Irradiation cross-linking oil resistance type soft low smoke zero halogen flame-retardant cable material

A technology of flame-retardant cables and inorganic flame retardants, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of low hardness, softness and oil resistance, etc., and achieve the effect of good flexibility and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

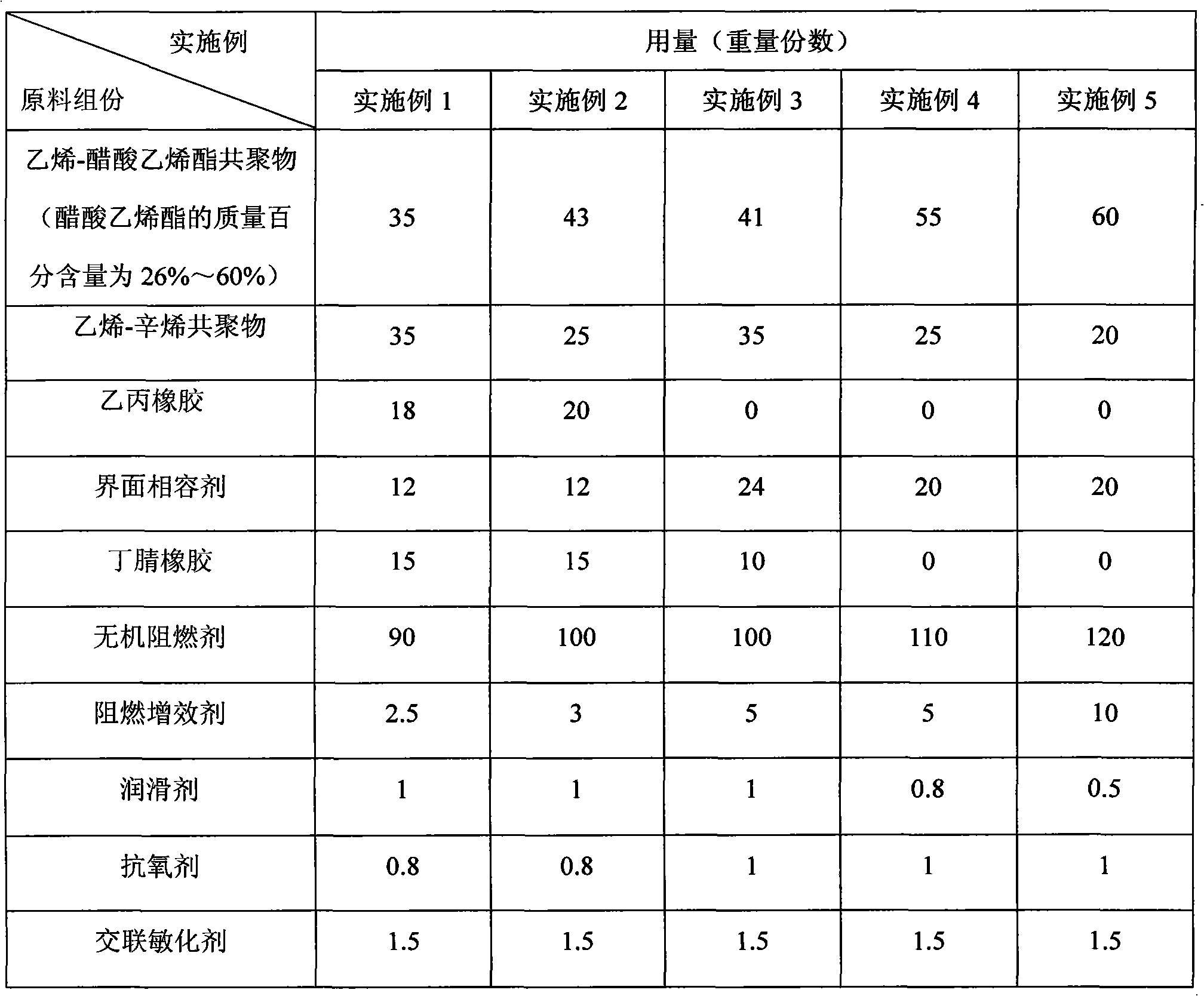

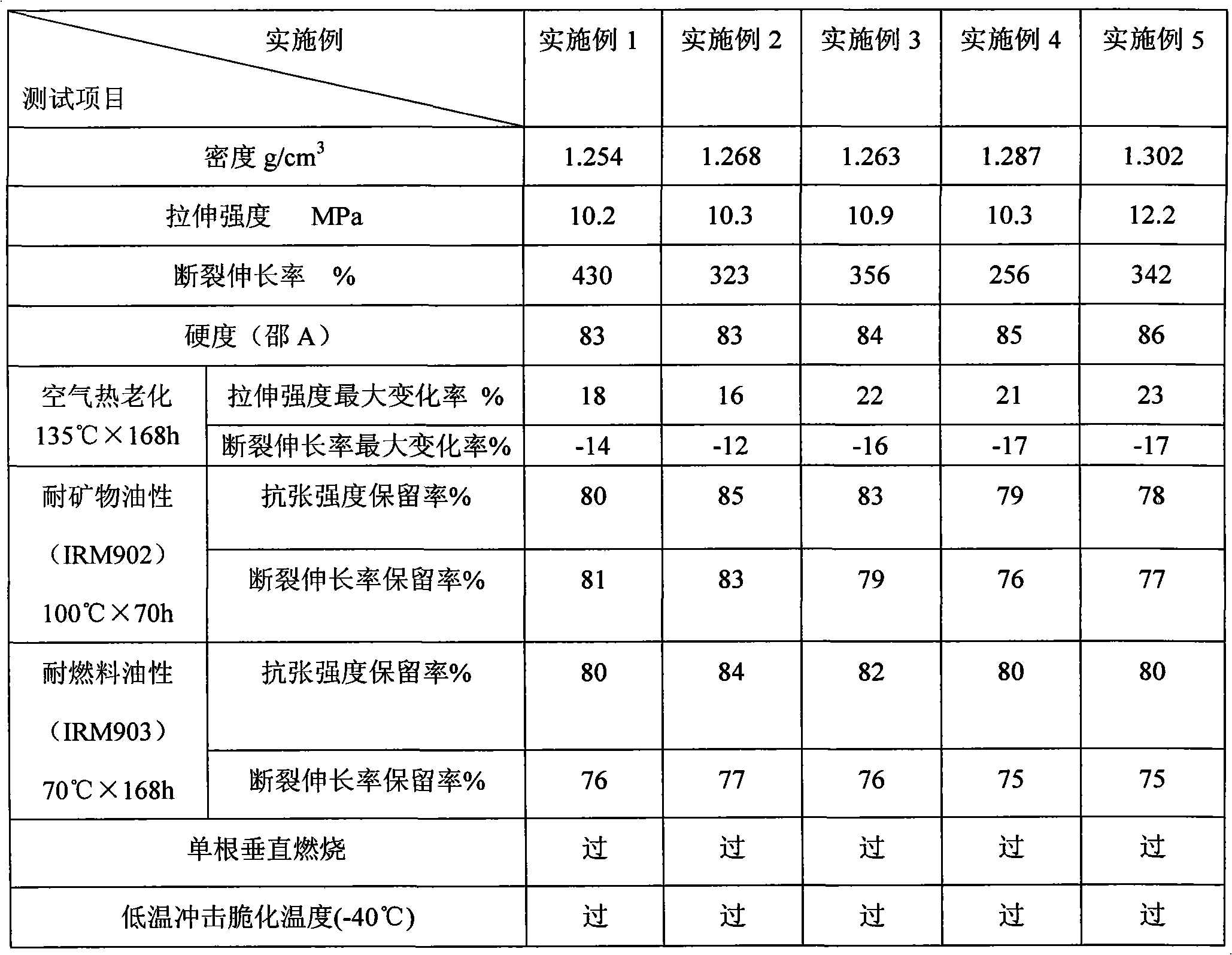

Examples

Embodiment 2

[0019] In embodiment 2, select vinyl acetate content to be respectively 33% and 50% ethylene-vinyl acetate copolymer, the ratio of the two is 2: 1, interface compatibilizer selects maleic anhydride grafted ethylene-propylene copolymer for use, Its Shore A hardness is 63, the inorganic flame retardant is magnesium hydroxide and aluminum hydroxide treated with silane, the ratio of the two is 2:1, the fineness is 5000 mesh, and the flame retardant synergist is red phosphorus and high molecular weight Silicone masterbatch, oxidized polyethylene wax and magnesium stearate as lubricant, tetrakis[methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol as antioxidant Ester and three [2.4-di-tert-butylphenyl] phosphite compound system, ratio is with example 1.

Embodiment 3

[0020] In embodiment 3, select vinyl acetate content to be respectively 33% and 40% ethylene-vinyl acetate copolymer, the ratio of the two is 1: 2, interface compatibilizer selects maleic anhydride grafted ethylene-octene copolymer for use , whose Shore A hardness is 78, and the inorganic flame retardant is magnesium hydroxide and aluminum hydroxide treated with silane, and the ratio of the two is 2:1. The fineness is 5000 mesh, the flame retardant synergist is made of red phosphorus and silicon rubber, the lubricant is made of oxidized polyethylene wax and paraffin wax, and the antioxidant is made of thiobisphenol antioxidant.

Embodiment 4

[0021] In embodiment 4, select vinyl acetate content to be respectively 28% and 33% ethylene-vinyl acetate copolymer, both ratios are 1: 1, interface compatibilizer selects maleic anhydride grafted ethylene-propylene copolymer for use, The Shore A hardness is 63, and the inorganic flame retardant is magnesium hydroxide and aluminum hydroxide treated with silane, and the ratio of the two is 2:1. The fineness is 5000 mesh, the flame retardant synergist is made of silicone masterbatch and silicone rubber masterbatch, the lubricant is made of oxidized polyethylene wax and magnesium stearate, and the antioxidant is made of thiobisphenol antioxidant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com