Piston for rotary compressor and manufacturing method of piston

A technology of a rotary compressor and a manufacturing method, which is applied in the direction of rotary piston/oscillating piston pump components, manufacturing tools, mechanical equipment, etc., and can solve problems such as high cost and large pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

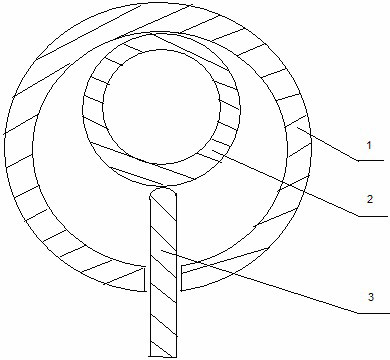

Image

Examples

Embodiment 1

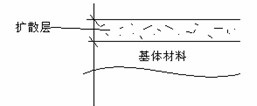

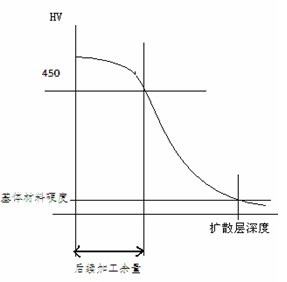

[0018] The piston is made of 20CrMnTi material, which is cold-extruded to form a piston base blank. After rough machining, it is subjected to heat stabilization treatment at 580°C for three times in an unprotected air furnace. After finishing, it is gas nitrided at a temperature of 550°C for 8 Hours, the gas is ammonia and carbon dioxide. After finishing, it reaches the use precision, forms a 30 um diffusion layer, and the surface hardness HV is greater than 450, which fully meets the use requirements.

Embodiment 2

[0020] The piston is made of 42CrMo material, and the piston base blank is formed by warm extrusion. After rough machining, heat stabilization treatment at 650°C is performed twice in a vacuum furnace, and ion nitriding is carried out after finishing machining. The temperature is 560°C and the time is 10 hours. , the gas introduced is ammonia and carbon dioxide. After finishing, it reaches the use precision, forms a 30 um diffusion layer, and the surface hardness HV is greater than 450, which fully meets the use requirements.

Embodiment 3

[0022] The piston is made of 38CrMoAi material, which is cold-rolled into a precision steel pipe and cut according to the size of the piston. After rough machining, it is subjected to a thermal stabilization treatment at 800°C in an ammonia cracking atmosphere protection furnace. After finishing machining, it is subjected to liquid salt bath nitriding treatment. at 570°C for 4 hours, the ion concentration CNO - % is 36%, CN - % is 4%, CO 2 2- % is 19%, Na + % is 21%, K + % is 19%, Li + % is 1.2%, and the use precision is reached after finishing, forming a diffusion layer of 50 um, and the surface hardness HV is greater than 450, which fully meets the use requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com