Porous polyimide oil storage and retention structure and preparation method and application thereof

A technology of polyimide and oil storage layer, which is applied in the field of porous polyimide oil storage and oil retention structure and its preparation, and can solve the problems that cannot meet the service life requirements of high-speed and high-precision bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

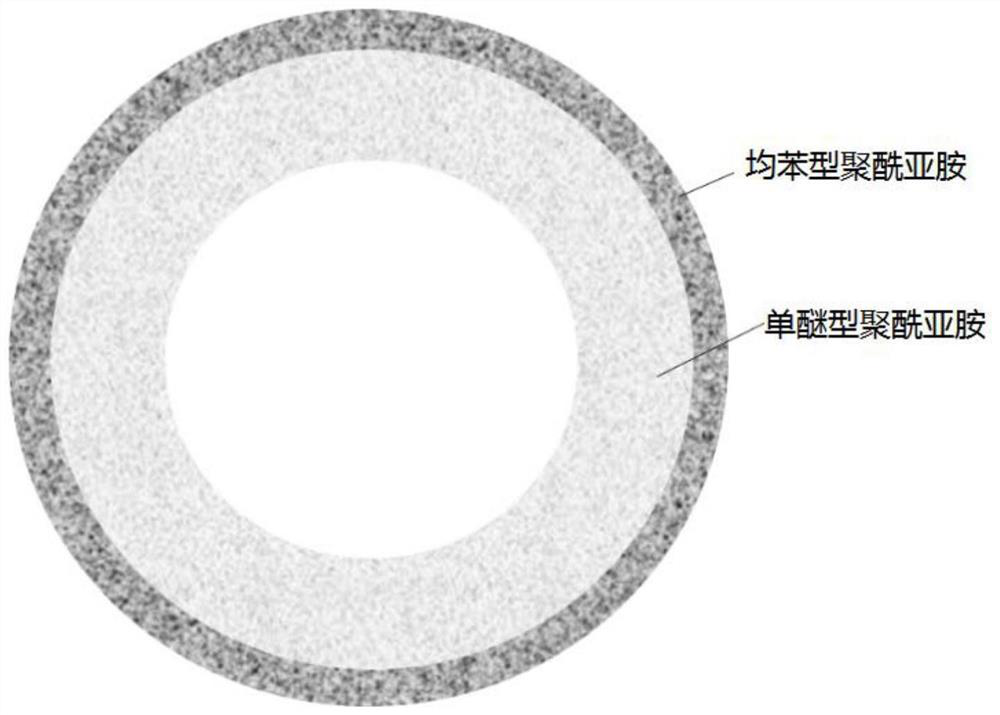

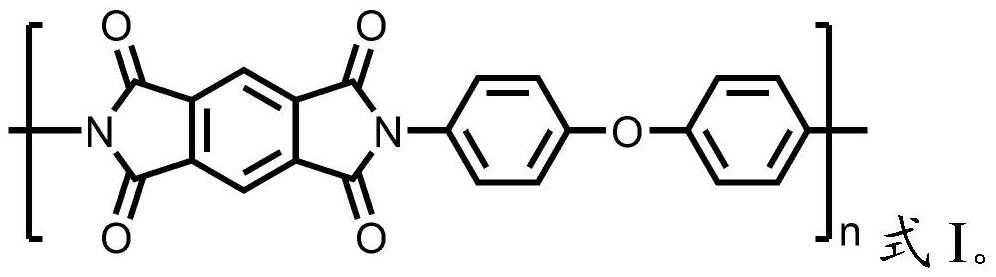

[0035] In the present invention, the homo-phenylene polyimide is preferably self-made, and the preparation method of the homo-phenylene polyimide preferably includes the following steps: in a protective atmosphere, the aromatic diamine 4,4' -Diaminodiphenylmethyl ether, pyromellitic anhydride and amide solvents are mixed and reacted to obtain an intermediate homogeneous solution; the intermediate homogeneous solution is mixed with a dehydrating agent for imidization reaction to obtain Benzene polyimide.

[0036] In the present invention, in a protective atmosphere, 4,4'-diaminodiphenylmethyl ether, pyromellitic anhydride and amide solvents are mixed and then reacted to obtain an intermediate homogeneous solution. In the present invention, the protective atmosphere is not particularly limited, and a protective atmosphere well known to those skilled in the art can be used, such as nitrogen or argon. In the present invention, the molar ratio of 4,4'-diaminodiphenylmethyl ether (...

Embodiment 1

[0062] (1) Under nitrogen protection atmosphere, room temperature, normal pressure, and stirring conditions, dissolve the aromatic diamine 4,4'diaminodiphenylmethanol (ODA) in an amide solvent, and then add an equal amount of the same substance Pyrylenetetracarboxylic anhydride (PMDA), and add solvent so that the total mass concentration of ODA and PMDA is 15wt%, stir and react at room temperature for 16h, obtain intermediate homogeneous solution; then add dehydrating agent toluene and mix uniformly in intermediate homogeneous solution , the temperature was raised to 155°C for imidization reaction, after the reaction was completed, the reaction system was poured into water to precipitate isophthalic polyimide, filtered, the obtained solid product was washed with ethanol, and vacuum-dried at 150°C to obtain homogeneous polyimide Benzene polyimide; wherein, the mass ratio of the intermediate homogeneous solution and toluene is 5:1.

[0063] (2) Sieve and classify the monoether p...

Embodiment 2

[0067] Prepare porous polyimide oil storage and oil retention structure according to the method of embodiment 1, and the difference with embodiment 1 is:

[0068] In step (2), the particle size of the monoether polyimide is 40-70 μm; the pressing pressure of the first cold isostatic press is 90 MPa;

[0069] In step (3), the pressure that the second cold isostatic press presses is 120MPa;

[0070] In step (4), the composite sintering temperature is 350° C., the pressure is 10 MPa, and the time is 30 minutes.

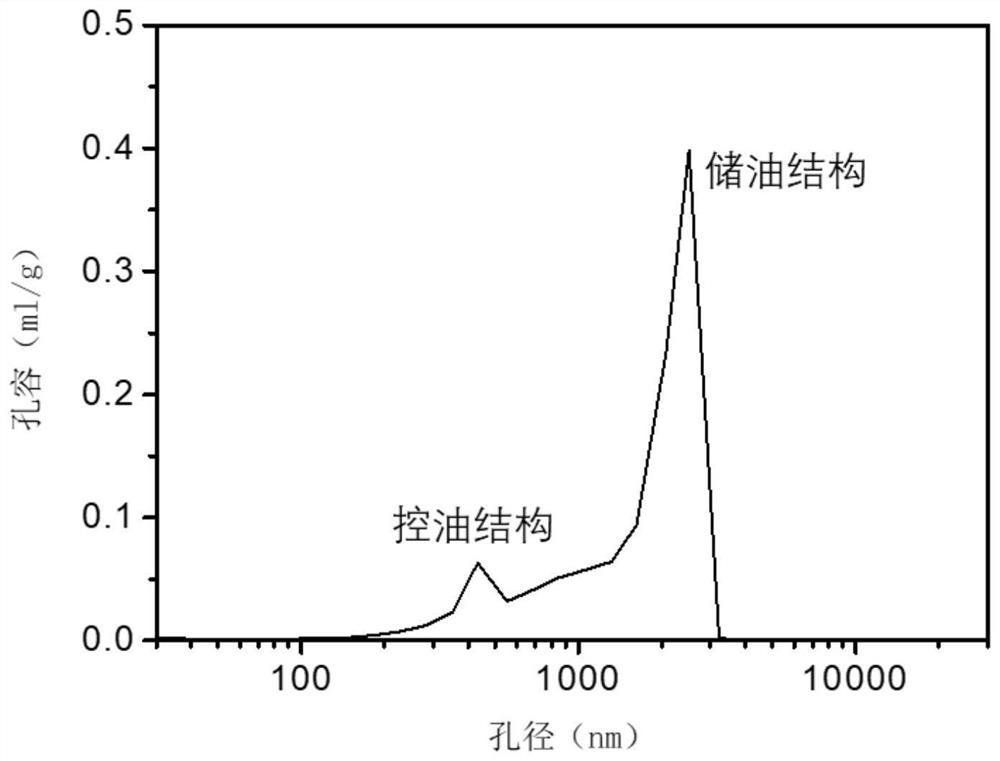

[0071] The pore size distribution diagram of the porous polyimide oil storage and oil retention structure prepared in this example is as follows figure 2 shown by figure 2 It can be seen that the pore size of the oil control layer of the porous polyimide oil storage and retention structure is mainly distributed in the range of 0.3-0.5 μm, the pore size of the oil reservoir is mainly distributed in the range of 1-2.25 μm, and the pore volume of the oil storage layer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com