Method for verifying internal leakage fault of aircraft brake valve

A verification method and brake valve technology, which is applied in the testing of mechanical components, testing of machine/structural components, testing of fluid tightness, etc., can solve problems such as the large gap between the valve core and valve sleeve, and save development resources and energy, eliminate internal leakage failure mode, and shorten the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

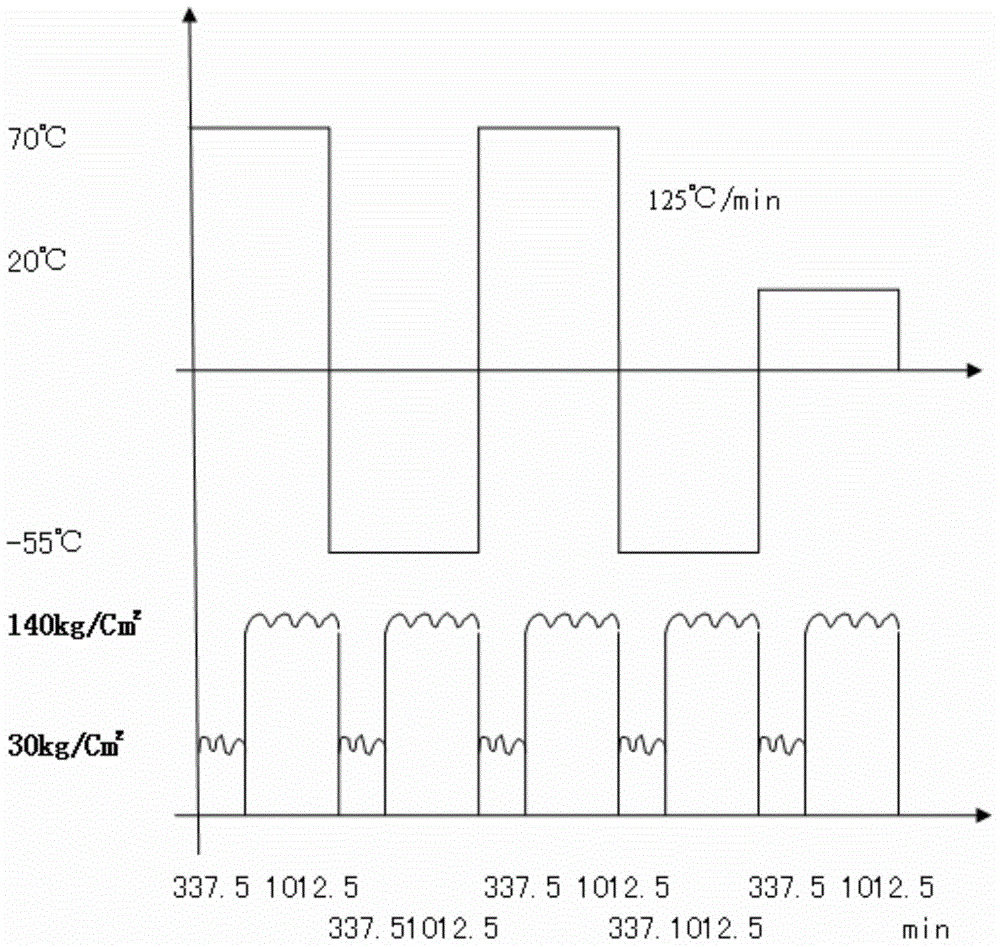

[0061] The brake valve of the aircraft brake system product of the present invention is a typical spring mass system, which is used to convert 210kg / Cm 2 The oil source pressure is converted to 140kg / Cm 2 brake pressure. The working principle is: when braking, the driver steps on the pedal, compresses the decompression spring, the spring force presses down the valve core, opens the oil inlet chamber, and makes the 210kg / cm 2 A part of the pressure oil enters the brake chamber and leads from the brake chamber to the brake wheel. The other part enters the pressure-sensing chamber through the oil hole inside the spool and acts on the bottom of the spool. When the pressure-sensing pressure at the bottom of the spool and the spring force reach a balance state, the spool moves to close the oil-inlet chamber.

[0062] The brake valve is composed of a spring assembly, slide valve assembly, sleeve assembly, housing, etc. During the assembly and debugging process, the spring force of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com