Synchronization device and method for producing a sliding sleeve of the same

A technology of sliding sleeve and synchronizing equipment, applied in mechanical equipment, mechanical driving clutch, clutch, etc., can solve the problem of large axial structure length, shift transmission installation space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

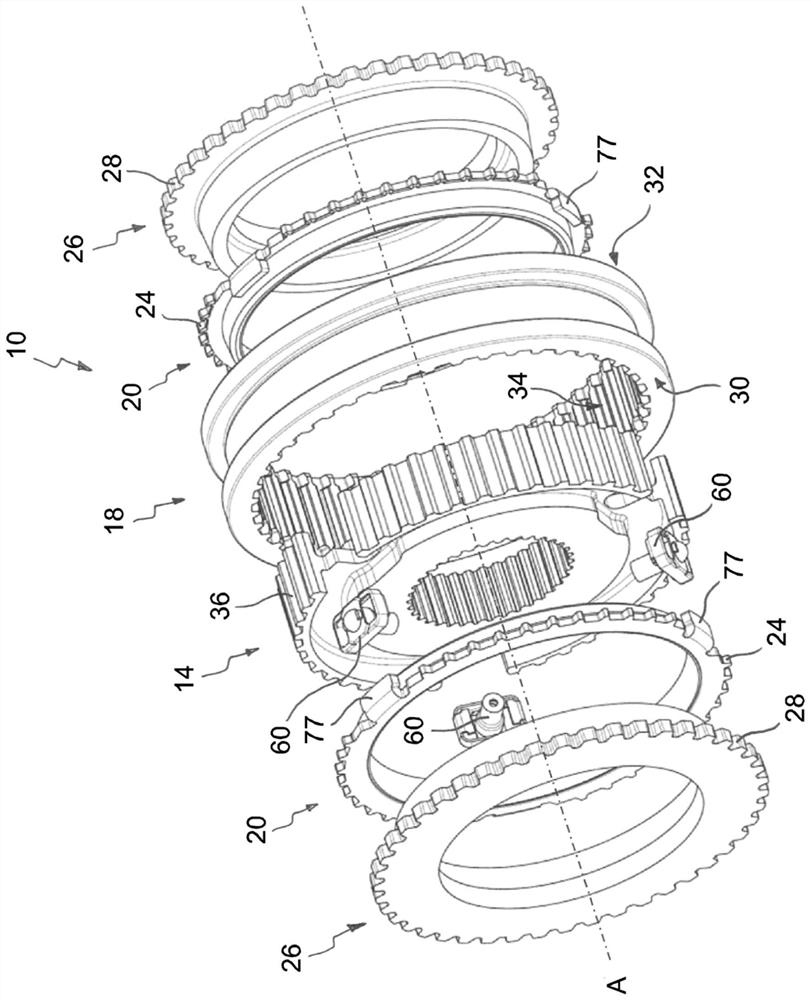

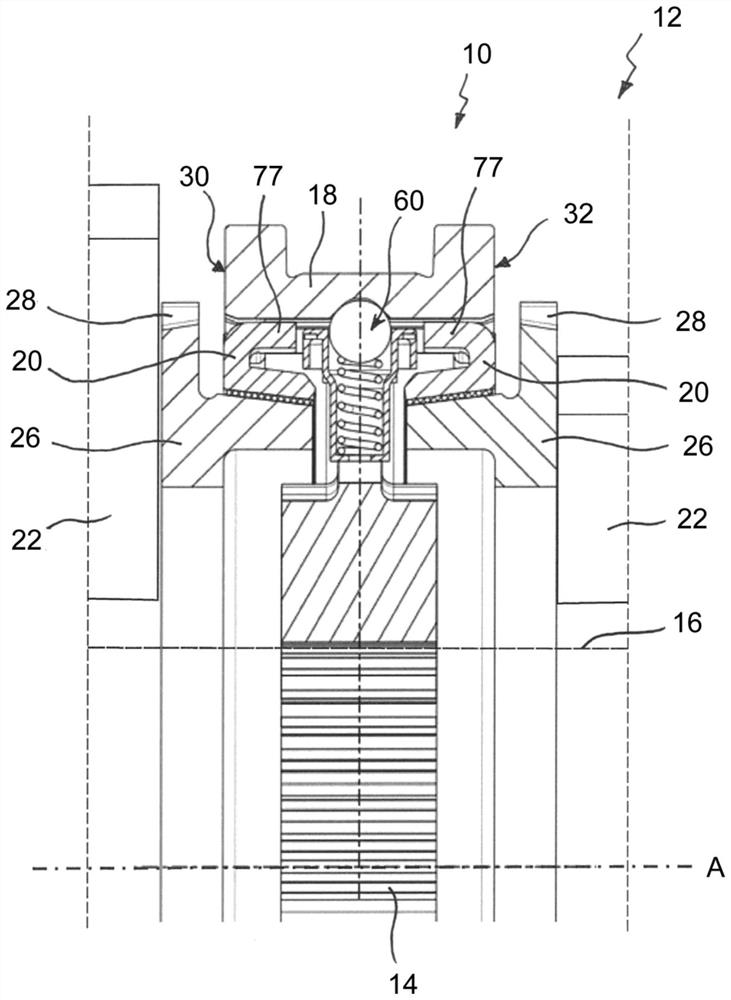

[0046] figure 1 and figure 2 Shown is a synchronizing device 10 for a gearshift transmission 12 of a motor vehicle, which has: a transmission shaft 16 rotatable about a longitudinal axis A; a hub 14 mounted on the transmission shaft 16 in a rotationally fixed manner; sliding a sleeve 18 , which is arranged in a rotationally fixed but axially displaceable manner relative to the hub 14 ; a synchronizer ring 20 for coupling the hub 14 to a gearwheel 22 of the shift transmission 12 via a frictional connection; and A clutch body 26 is connected in a rotationally fixed manner to the gearwheel 22 .

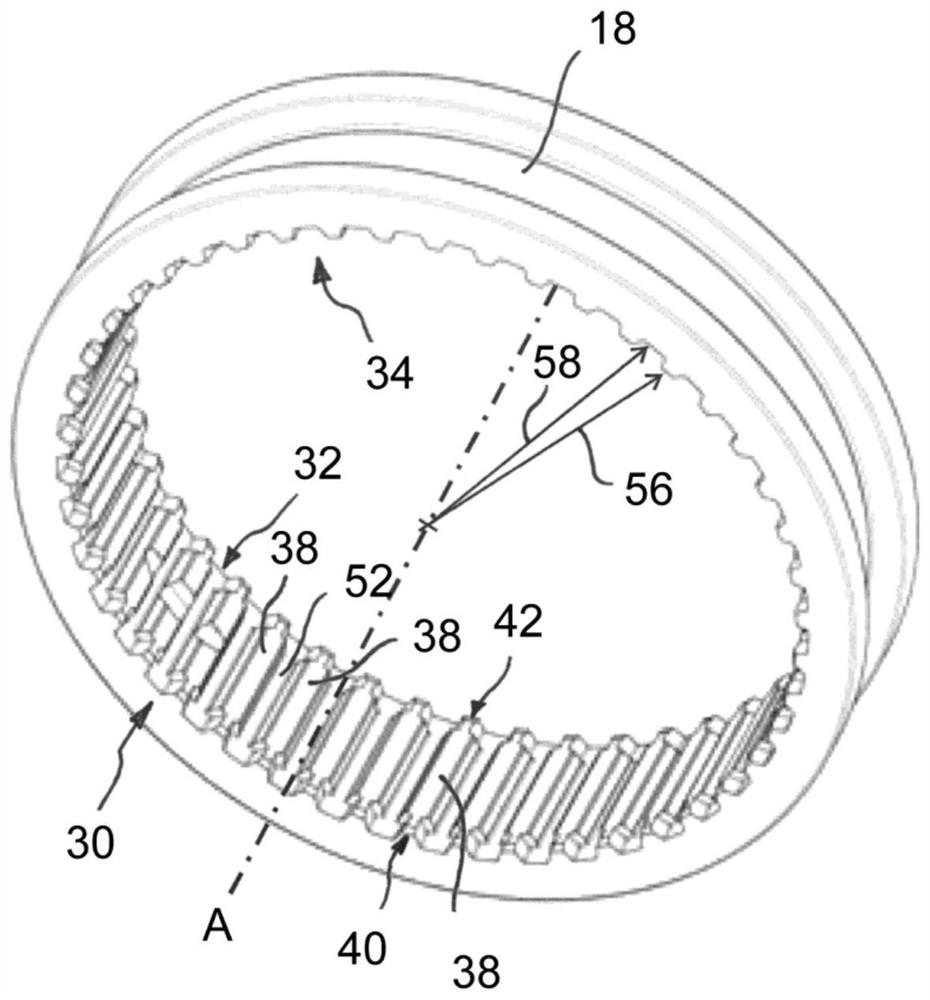

[0047] Synchronizer ring 20 has synchronizer outer toothing 24 and clutch body 26 has clutch body outer toothing 28 .

[0048] The sliding sleeve 18 of the synchronization device 10 is rotatable about the longitudinal axis A and comprises an internal toothing 34 which engages in an external toothing 36 of the hub 14 . In the corresponding axial position of the sliding sleeve 18 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com