Rear suspension bracket cushion assembly

A rear mount and assembly technology, which is applied in the power plant, jet propulsion device, internal combustion propulsion device, etc., can solve the problem of the inability to meet the service life of the car, the inability to meet the stiffness and strength, the vibration reduction effect, the limit performance and the fatigue resistance performance. Insufficient and other problems, to achieve the effect of excellent vibration reduction effect, high strength, good limit performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

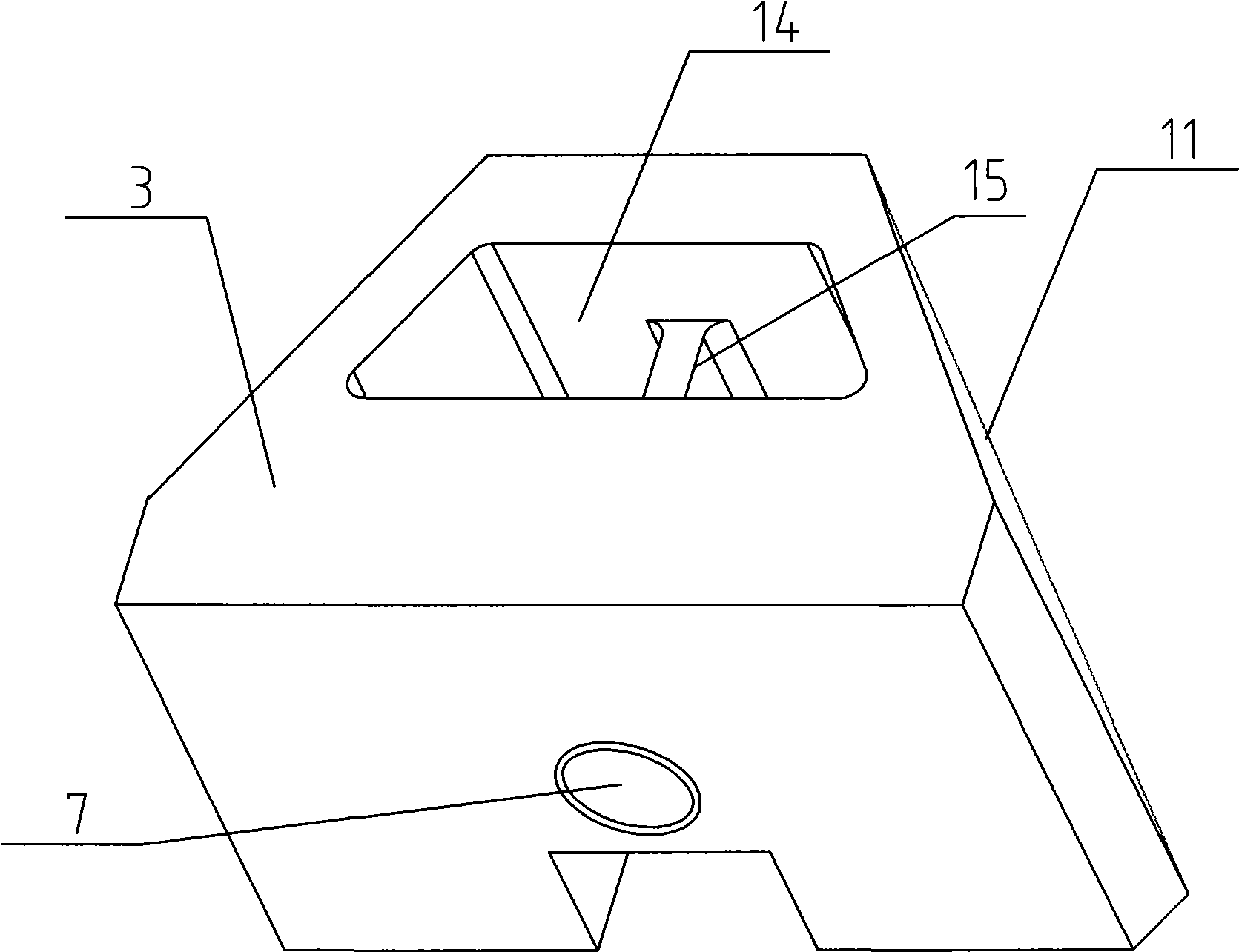

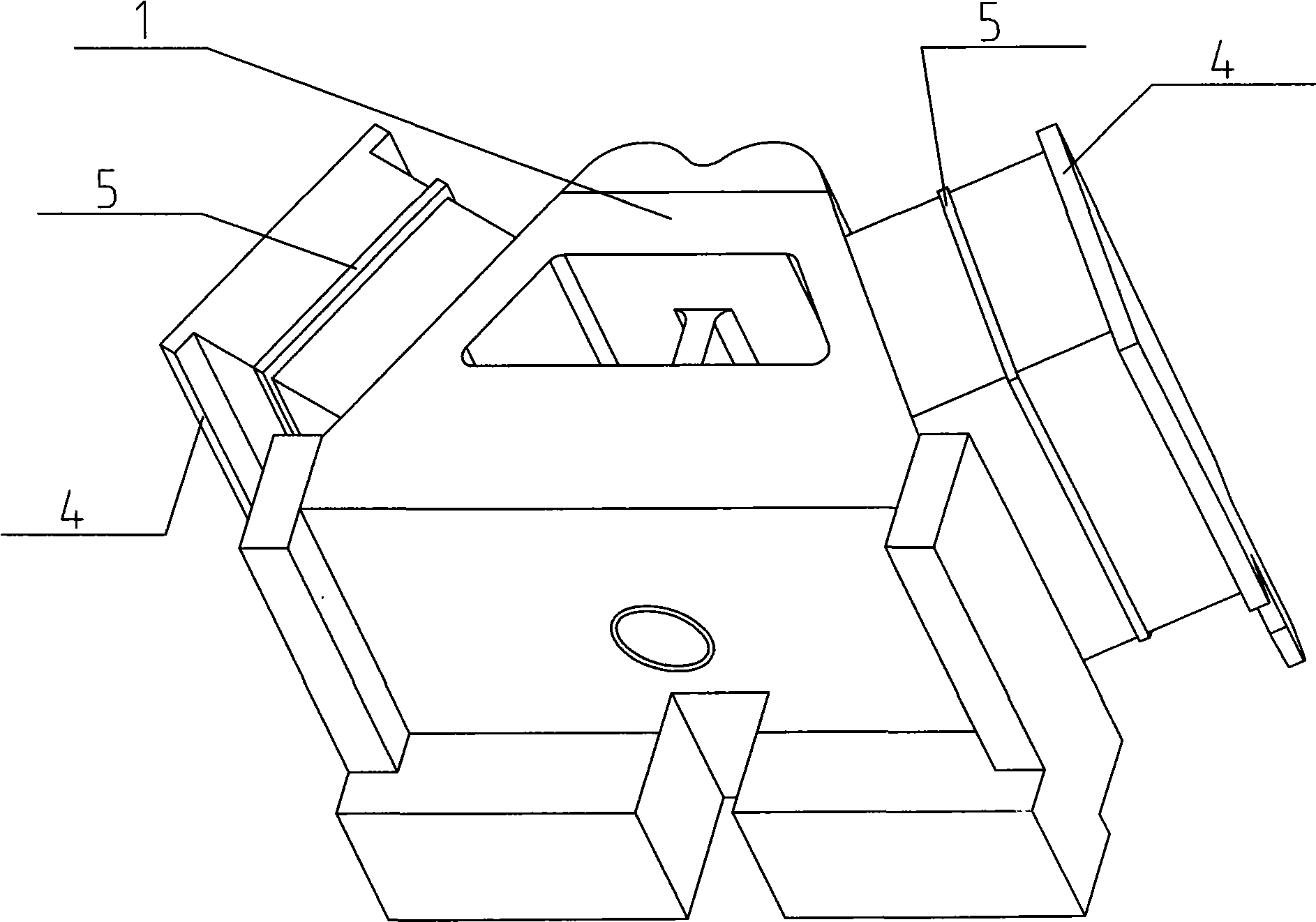

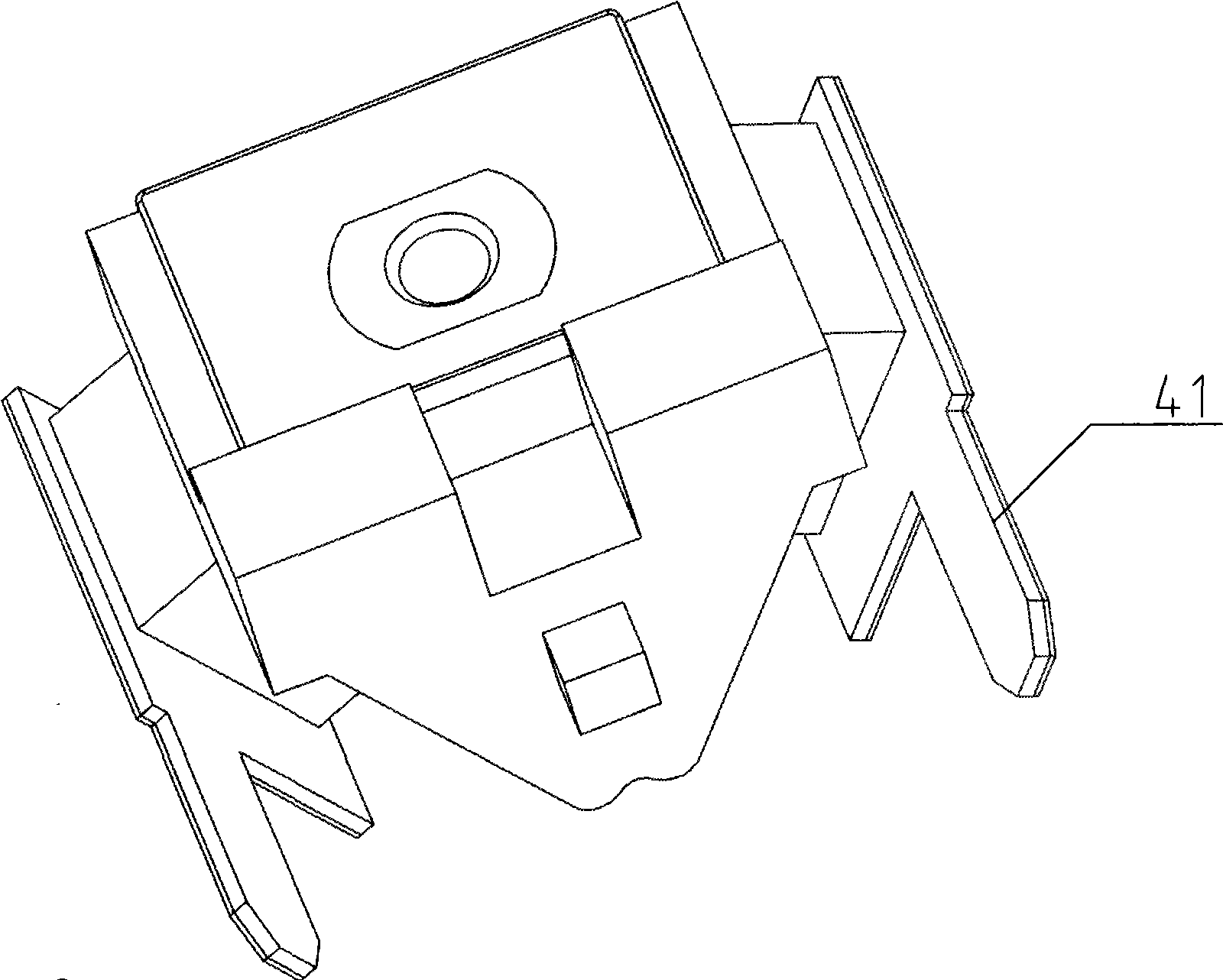

[0017] like Figure 5 shown, combined with Figure 1-4 as well as Figure 6 , Figure 7 Illustrate that the rear suspension bracket cushion assembly for the heavy-duty vehicle high-power engine of the present invention is composed of a rear suspension cushion assembly 1 and a rear suspension bracket assembly 2. Among them, the rear suspension cushion assembly 1 is inserted into the inner cavity of the rear suspension bracket assembly 2, and a certain pressure ( Figure 7 medium Z-direction load) until the two pieces fit together completely. Then its protruding part 41 of the steel limit plate 4 on the rear suspension soft cushion assembly (such as image 3 ) until it is flat against the bracket assembly (such as Figure 6 shown).

[0018] In the figure, the rear suspension cushion assembly 1 is an upper seat 3 made of die-cast aluminum (or cast steel or cast iron), a steel limiting plate 4, a steel middle plate 5 and a vulcanized integrated rubber between them. Composed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| V-shaped angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com