Spring bushing assembly for automobile front steel plates, and production process thereof

A leaf spring and assembly technology, which is applied in the field of automobile front leaf spring bushing assembly and its production process, can solve the problems of low service life, affecting automobile shock absorption performance, unsatisfactory compression stiffness and torsional stiffness, etc., and achieve high Strength, excellent vibration damping effect, excellent fatigue resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

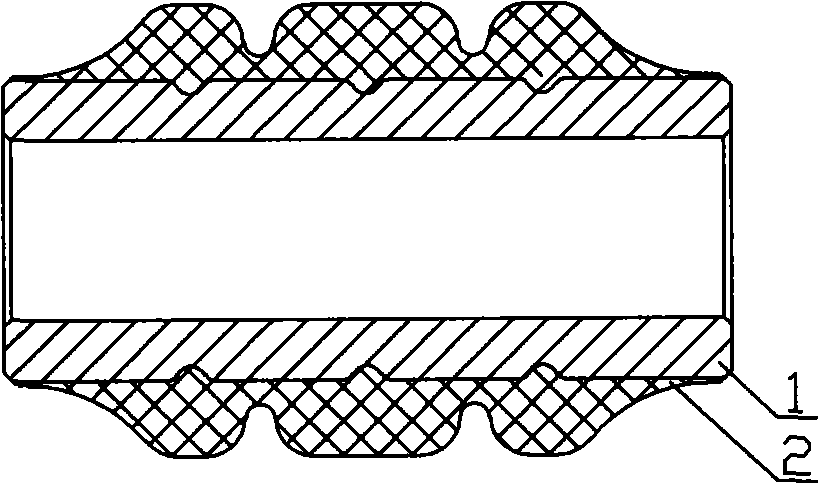

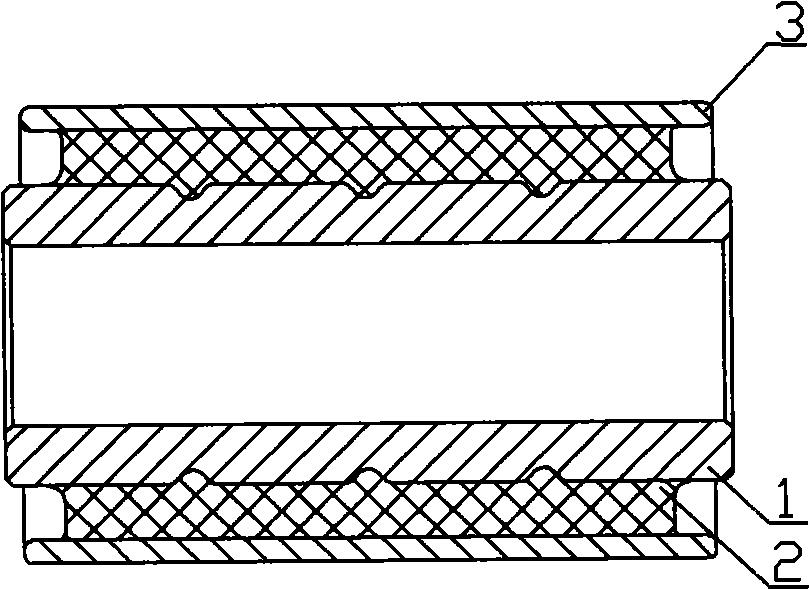

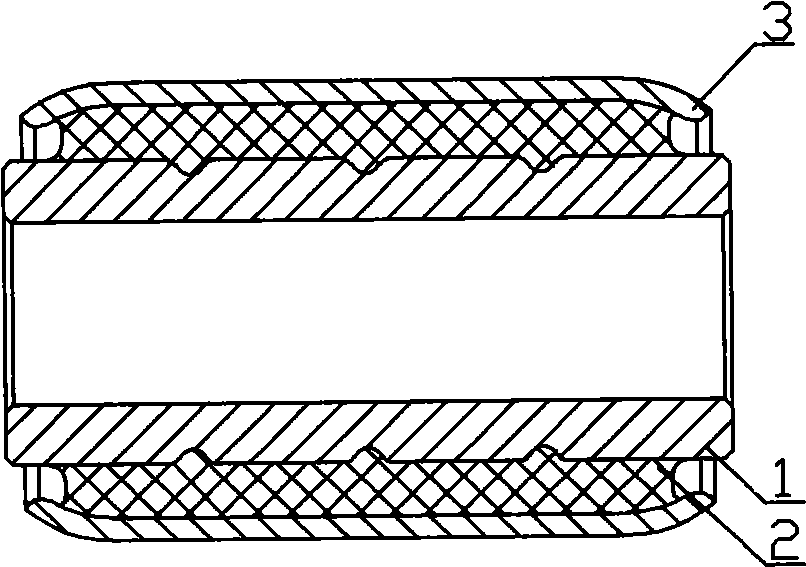

[0016] figure 1 , figure 2 and image 3 It is a preferred embodiment of the automobile front leaf spring bushing assembly and its production process of the present invention: the automobile front leaf spring bushing assembly includes an inner sheath 1, a rubber assembly 2 and an outer sheath 3; the rubber assembly 2 is nested on the outside of the inner sheath 1; the outer sheath 3 is nested on the outside of the rubber assembly 2; there are three arc-shaped grooves on the outer diameter of the inner sheath 1, and the rubber is vulcanized and fixed on the outer diameter of the inner sheath 1. The inner sheath 1 is circular, with chamfers on both sides of its inner hole, and an arc groove in the middle of its outer diameter; the rubber assembly 2 is circular; the outer sheath 3 is circular, and its two sides It is in the shape of a tapered hole, with a cylindrical ring in the middle; the outer sheath 3 is made by reducing the diameter and closing the mouth twice. The outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com