Method of manufacturing polarization maintaining optical fiber

A technology for polarization-maintaining optical fibers and manufacturing methods, which is applied to cladding optical fibers, manufacturing tools, glass manufacturing equipment, etc., can solve problems such as easy fiber breakage, difficult optical fibers, and insufficient cladding out-of-roundness, etc., so as to improve mechanical strength, The effect of improving the mechanical performance and satisfying the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

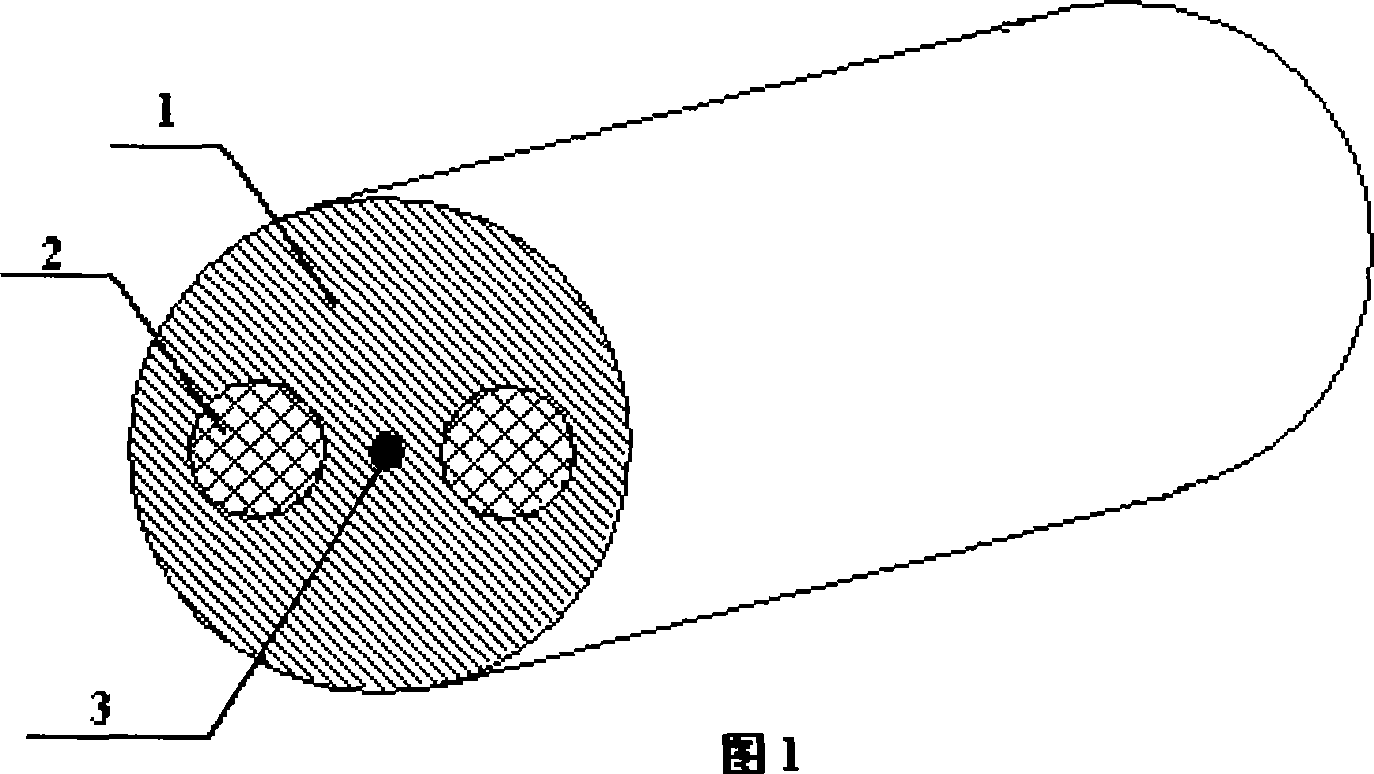

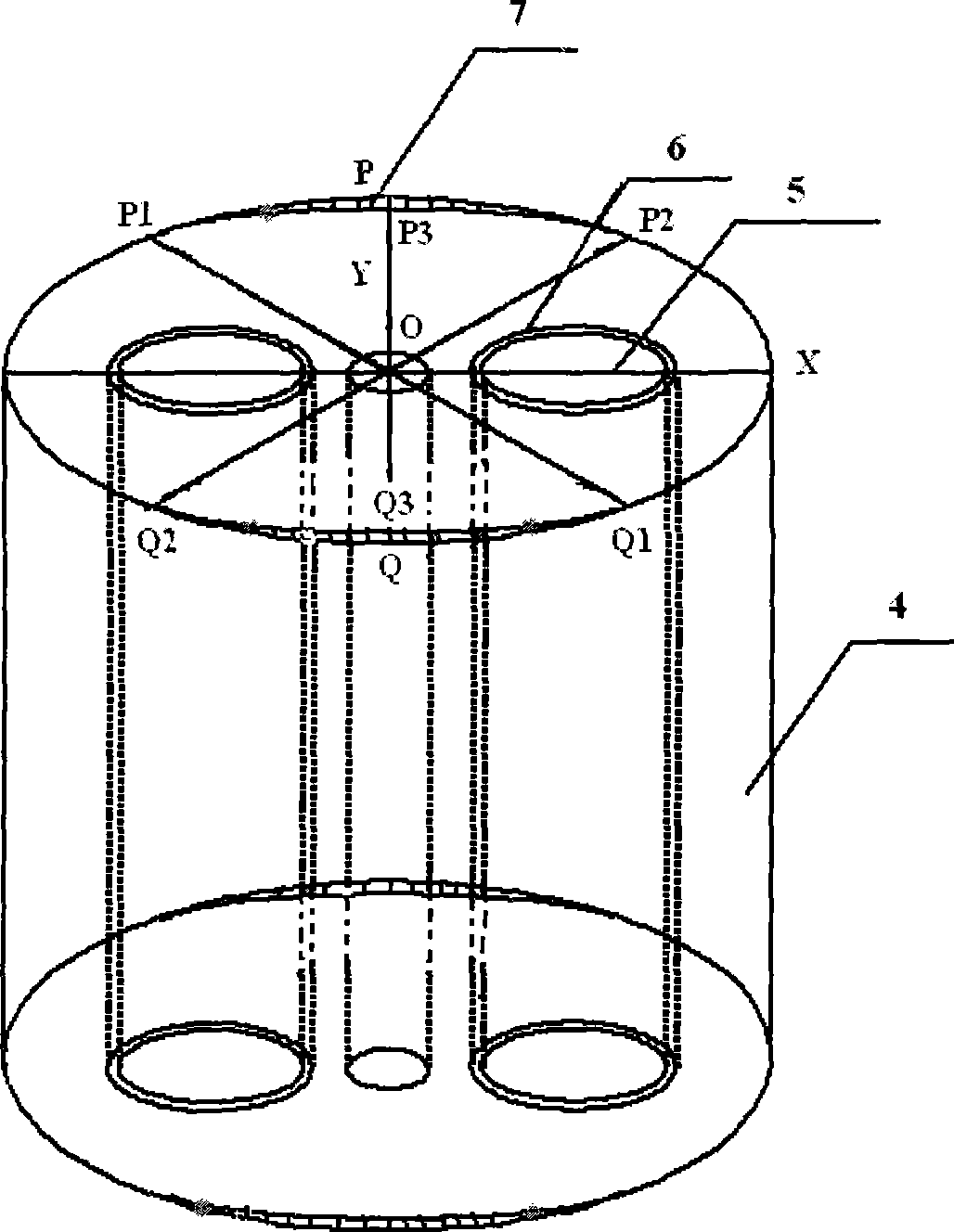

[0047] Use PCVD method to deposit and manufacture optical fiber core rods and stress rods, insert the core rods into the quartz sleeves, clean and dry them, and then go to the drawing tower to stretch the core rods and sleeve tubes into integrated optical fiber preform rods with a diameter of 50 mm. Holes were symmetrically drilled on both sides of the core of the manufactured optical fiber preform, and the diameter of the holes was 16 mm. At the same time, the diameter of the stress rod manufactured by deposition is adjusted to 15.2 mm by mechanical or corrosion methods. Since the 15.2mm diameter stress rod is inserted into the 16mm hole, the gap between the stress rod and the hole is 0.4mm. Using the HF acid etching process, the side of the perforated preform perpendicular to the direction of the double holes is immersed in the acid solution (such as image 3 P 1 PP 2 surface), the depth of immersion in the acid solution gradually changes from 0mm to 0.6mm, that is, the p...

Embodiment 2

[0049] Use PCVD method to deposit and manufacture optical fiber core rods and stress rods, insert the core rods into the quartz sleeves, clean and dry them, and then go to the drawing tower to stretch the core rods and sleeve tubes into integrated optical fiber preform rods with a diameter of 50 mm. Holes were symmetrically drilled on both sides of the core of the manufactured optical fiber preform, and the diameter of the holes was 16 mm. At the same time, the diameter of the stress rod manufactured by deposition is adjusted to 15.2 mm by mechanical or corrosion methods. Since the 15.2mm diameter stress rod is inserted into the 16mm hole, the gap between the stress rod and the hole is 0.4mm. Using the HF acid etching process, the side of the perforated preform perpendicular to the direction of the double holes is immersed in the acid solution (such as image 3 P 1 PP 2 surface), the depth of immersion in the acid solution gradually changes from 0mm to 0.8mm, that is, the p...

Embodiment 3

[0051]Use PCVD method to deposit and manufacture optical fiber core rods and stress rods, insert the core rods into the quartz sleeves, clean and dry them, and then go to the drawing tower to stretch the core rods and sleeve tubes into integrated optical fiber preform rods with a diameter of 50 mm. Holes were symmetrically drilled on both sides of the core of the manufactured optical fiber preform, and the diameter of the holes was 16 mm. At the same time, the diameter of the stress rod manufactured by deposition is adjusted to 15.2 mm by mechanical or corrosion methods. Since the 15.2mm diameter stress rod is inserted into the 16mm hole, the gap between the stress rod and the hole is 0.4mm. Using the HF acid etching process, the side of the perforated preform perpendicular to the direction of the double holes is immersed in the acid solution (such as image 3 P 1 PP 2 surface), the depth of immersion in the acid solution gradually changes from 0mm to 1.0mm, that is, the pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com