Continuous oriented glass fiber-reinforced high-flame retardance and low-water absorption rate sheet molding compound and preparation method thereof

A technology of sheet molding compound and glass fiber, which is applied in the field of composite materials, can solve the problems of heavy weight, low water absorption performance, and no materials involved, and achieve the effect of high addition, high flame retardancy, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

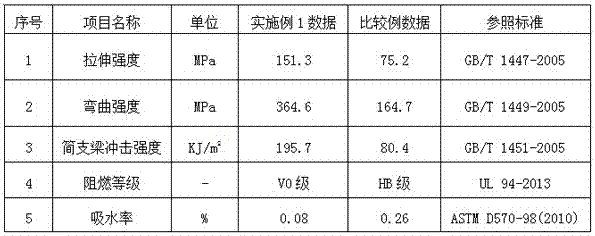

Examples

preparation example Construction

[0033] In this embodiment, a method for preparing a continuously oriented glass fiber reinforced sheet molding compound with high flame retardancy and low water absorption comprises the following steps:

[0034] a. Weigh the unsaturated polyester resin, low shrinkage agent, styrene, filler, initiator, polymerization inhibitor, internal mold release agent and processing aid according to a certain proportion, and fully stir and mix to obtain a resin paste;

[0035] b. Mixing the thickener with the carrier resin to obtain a thickener paste;

[0036] c. The resin paste and the thickener paste are mixed through the online mixing system of the sheet molding compound production unit, and then compounded with continuous oriented glass fiber and chopped glass fiber, and the sheet is obtained through the process of impregnation and compaction;

[0037] d. Place the sheet at a certain temperature to mature, and when the indentation hardness reaches a certain range, a continuously oriente...

Embodiment 1

[0039] Prepare 37 kg of isophthalic resin, 13 kg of polymethyl methacrylate, 2 kg of polyethylene micropowder, 1.5 kg of styrene, 75 kg of aluminum hydroxide, 42.5 kg of glass fiber (oriented continuous fiber and short fiber with a chopped length of 25.4 mm The ratio is 5:1), tert-butyl peroxybenzoate 0.65 kg, p-benzoquinone 0.02 kg, magnesium oxide 0.60 kg, zinc stearate 2.2 kg, BYK996 additive 0.5 kg, BYK972 additive 0.4 kg.

[0040]The above chemical raw materials except the thickener paste are weighed according to a predetermined ratio and fully mixed with a high-speed mixer to obtain a resin paste with a viscosity of about 120 P; the resin paste and the thickener paste are passed through the sheet molding compound production unit Mixed in an online mixing system, compounded with continuous oriented glass fiber and chopped glass fiber, and then impregnated and compacted to obtain a sheet molding compound sheet; place the sheet at 45°C for curing until the hardness reaches 3...

Embodiment 2

[0042] Prepare 34 kg of vinyl ester resin, 16 kg of polystyrene, 2.5 kg of polyethylene micropowder, 2.5 kg of styrene, 85 kg of aluminum hydroxide, and 41 kg of glass fiber (the ratio of oriented continuous fiber to short fiber with a chopped length of 25.4 mm 4:2), tert-butyl peroxyisopropyl carbonate 0.5 kg, p-benzoquinone 0.01 kg, magnesium oxide 0.55 kg, zinc stearate 2.5 kg, BYK996 additive 1.0 kg, BYK972 additive 0.5 kg.

[0043] Weigh the above chemical raw materials except the thickener paste according to a predetermined ratio and fully mix them with a high-speed mixer to obtain a resin paste with a viscosity of about 105 P; pass the resin paste and thickener paste through the sheet molding compound production unit Mixed in an online mixing system, compounded with continuous oriented glass fiber and chopped glass fiber, and then impregnated and compacted to obtain a sheet molding compound sheet; place the sheet at 45°C for curing until the hardness reaches 350-450 Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com