Reactive compensation equipment with LED (light emitting diode) constant-current driver

A compensation equipment, constant current drive technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation, lighting and heating equipment, etc. Adaptation and other problems to achieve the effect of meeting the requirements of LED service life, convenient maintenance and repair, and less electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

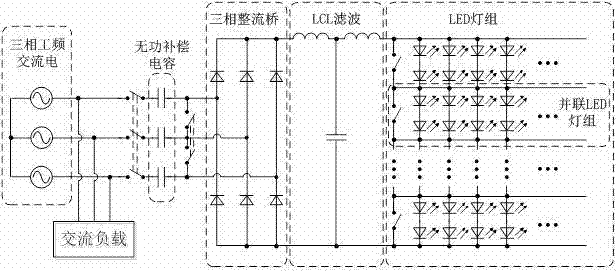

[0017] The schematic diagram of the circuit structure of the present invention is as figure 1 As shown, it includes three-phase power frequency AC power supply, reactive power compensation capacitor, three-phase rectifier bridge, LCL filter and LED lamp group connected in sequence, where each phase of the three-phase power frequency AC power is connected to a reactive power compensation capacitor through a switch One end and the other end of the reactive power compensation capacitor are connected to the midpoint of the corresponding bridge arm on the three-phase input side of the three-phase rectifier bridge. On the side of the reactive power compensation capacitor close to the rectifier bridge, there are two switches. When the two switches When the conduction is closed at the same time, the three reactive power compensation capacitors form a star connection. In order to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com