Novel structure for polyethylene reinforced compound pipe

A reinforced composite and polyethylene technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of poor crack resistance of the outer wall of the composite pipe, low strength of the inner wall of the composite pipe, easy cracking or peeling, etc., to achieve Improved quality and reliability, high pressure bearing capacity and smooth inner wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

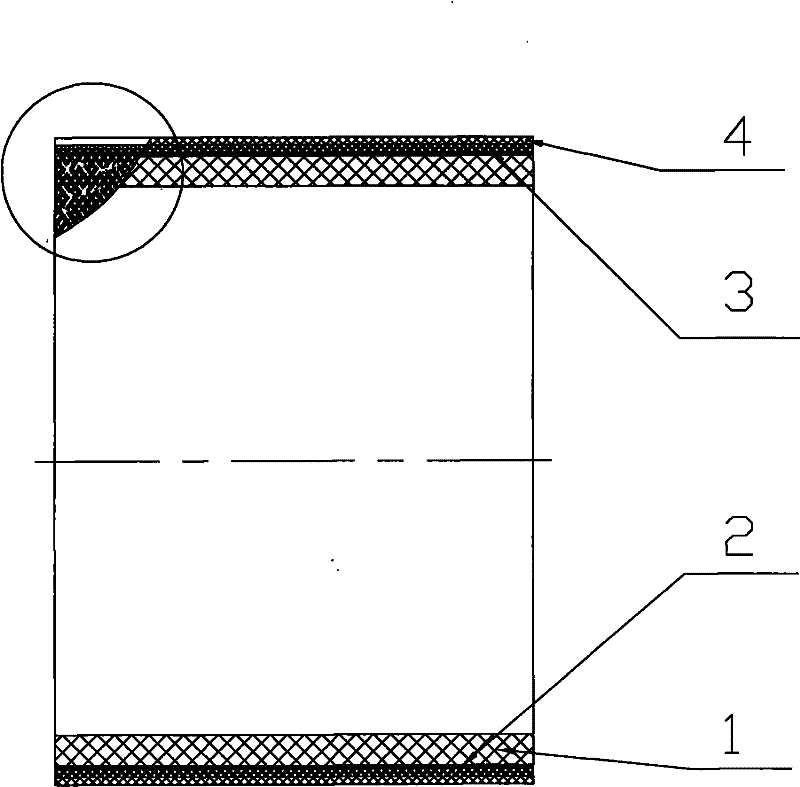

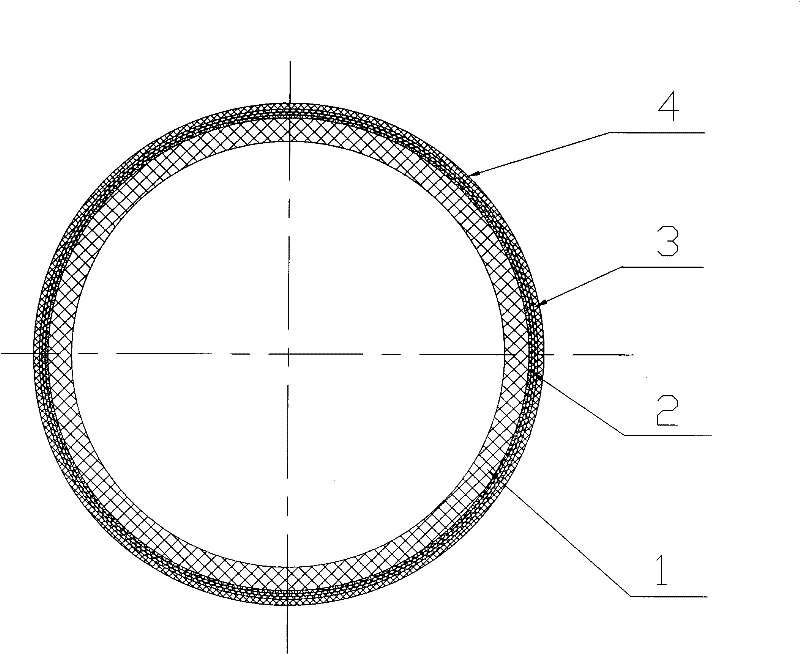

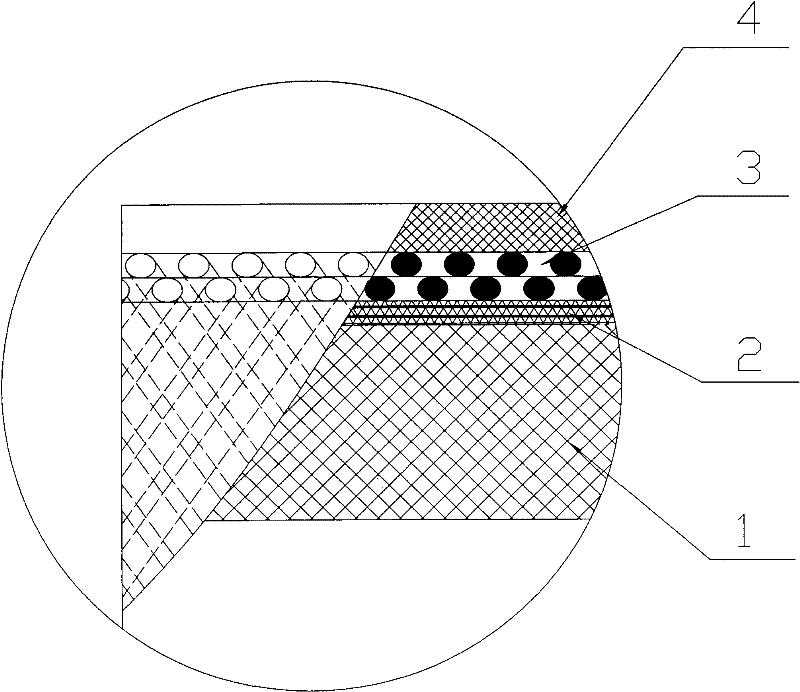

[0026] The present invention as figure 1 , figure 2 , image 3 As shown, a new type of polyethylene reinforced composite pipe structure includes a base pipe, a metal reinforcement layer, a fiber reinforcement layer, and an outer wall. The fiber reinforcement layer and the metal reinforcement layer are provided with at least one layer, placed between the base pipe and the Between the outer walls, between the base tube and the fiber-reinforced layer, between the fiber-reinforced layer and the metal-reinforced layer, between the metal-reinforced layer and the metal-reinforced layer, are bonded together with special polyethylene glue by heating.

[0027] The fiber-reinforced layer is placed between the base pipe and the metal-reinforced layer, arranged equidistantly from the axis of the pipe at an angle of 0°, and arranged as one layer.

[0028] The metal reinforcement layer is placed between the fiber reinforcement layer and the outer wall, at an angle of 60° to the axis of th...

Embodiment 2

[0033] The present invention as Figure 4 , Figure 5 , Image 6 As shown, the pipe structure is the same as that of Example 1, except that the fiber reinforced layer is set in two layers, and the metal reinforced layer has two layers of right-helical winding layers and left-helical winding layers.

[0034] Example 2 The nominal pressure of the pipe is 11-15MPa.

[0035] Pipes are manufactured by special equipment.

[0036] In summary, the present invention has the advantages of reasonable structural design, strong wear resistance and corrosion resistance, and high pressure bearing capacity. Compared with existing pipes, its pressure bearing capacity is increased by 2-3 times, and it can replace Steel pipe is a new polyethylene reinforced composite pipe structure with wide application range and long service life.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| bearing capacity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com