Transformer coil bending-shaped oil guide system

A technology of transformer coil and zigzag shape, which is applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor cooling, etc. To solve problems such as rising and falling, to achieve excellent performance parameters, good cooling effect, and reduce the effect of coil temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

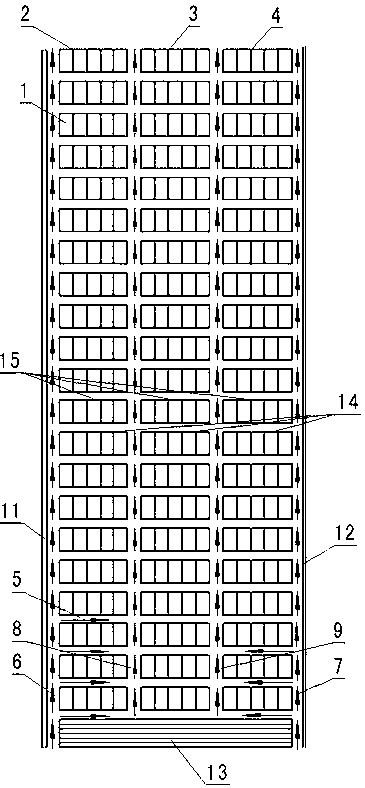

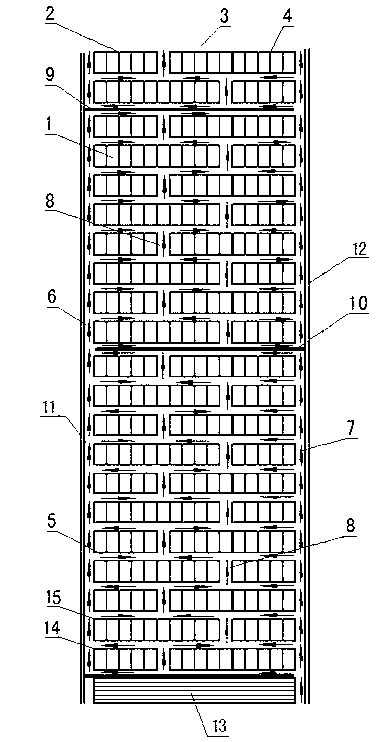

[0012] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment is a transformer coil zigzagging oil guiding system, which is characterized in that it includes a coil wire 1, a transverse oil passage 5, a longitudinal oil passage 6 on the inner diameter side of the coil, a longitudinal oil passage 7 on the outer diameter side of the coil, and a longitudinal oil passage 8 in the coil , the inner oil retaining ring 9 and the outer oil retaining ring 10; each wire cake in the coil is composed of the first part of the coil inner diameter side of the coil 2, the middle second part of the wire cake 3 and the third part of the coil outer diameter side The line cake 4 is composed of; when the second part of the line cake 3 is in the odd number of line cake 14, no longitudinal oil passage is designed between the third part of the line cake 4 of the same cake, and when the second part of the line cake 3 is in the even number of line cake 15 There i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com