Balance suspension plate spring seat lining assembly

A technology of balanced suspension and leaf spring, which is applied in the field of bushings, can solve the problems of unsatisfactory service life, uneven stiffness and strength, easy deformation of impact, etc., and achieve excellent vibration damping effect, high bonding performance, and reduced impact Effects of deformation and dynamic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

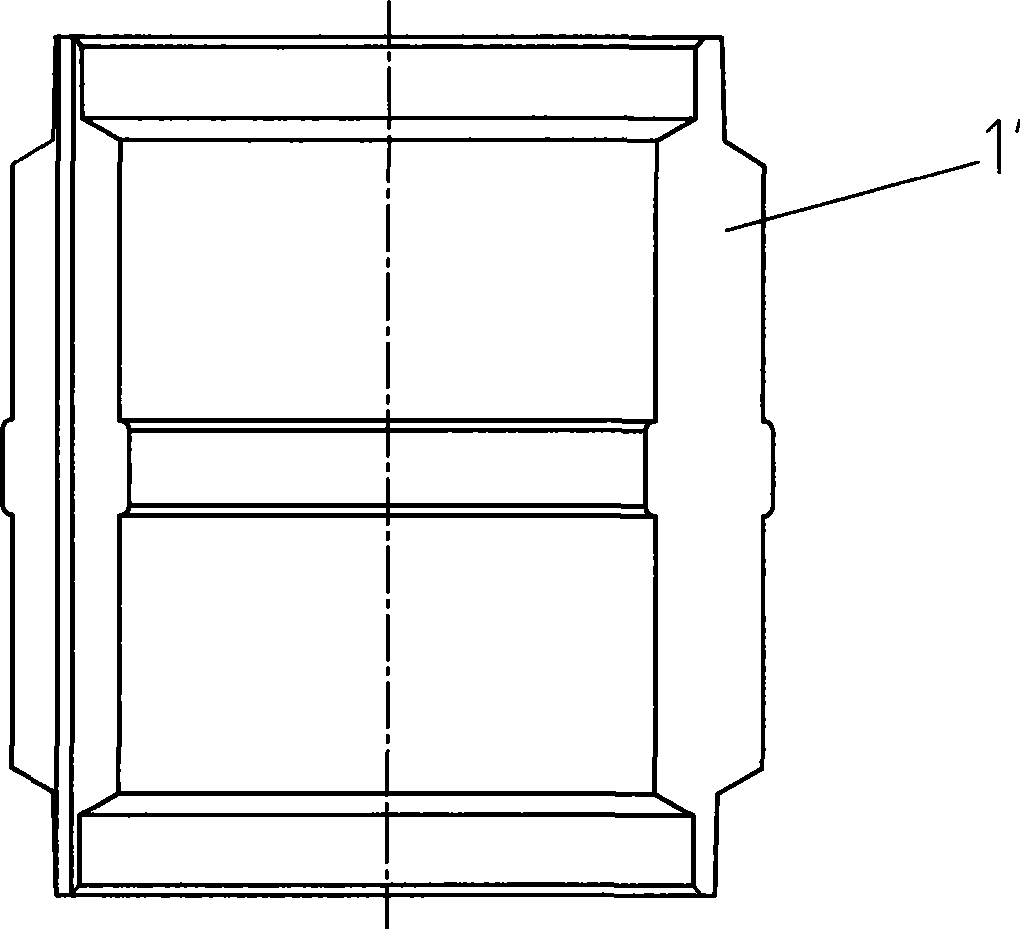

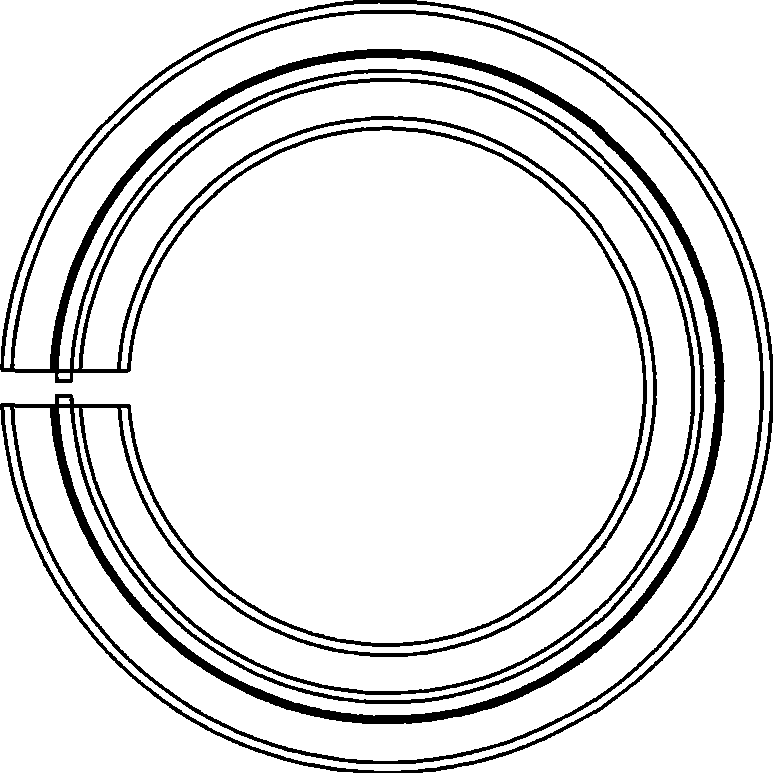

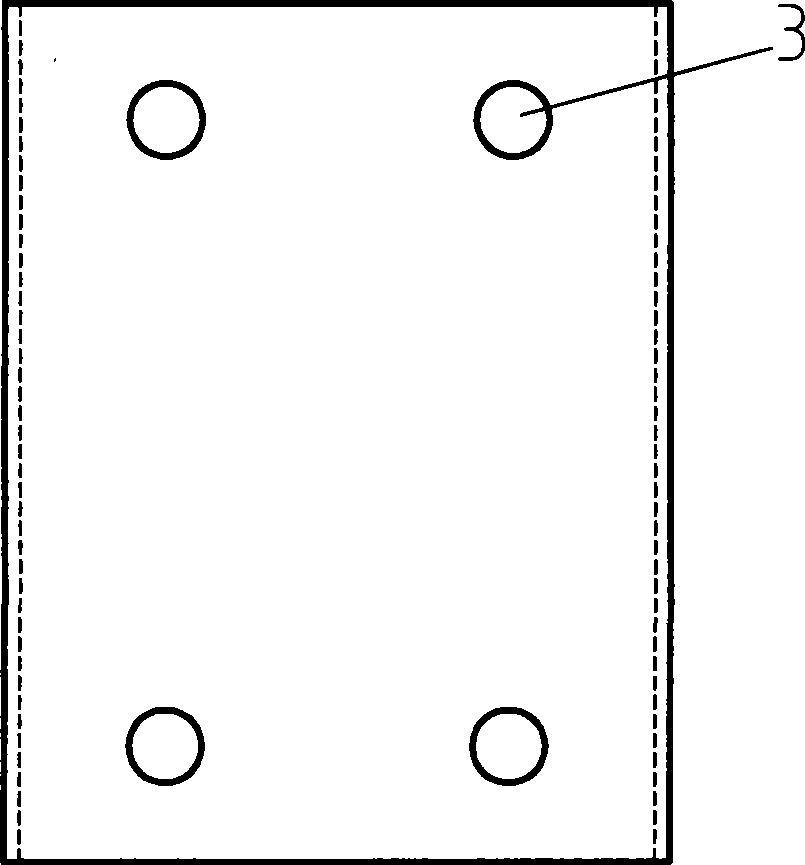

[0014] Such as figure 1 shown, refer to Figure 2-4 Describe the leaf spring seat bushing assembly of the balance suspension for automobiles of the present invention. Such as image 3 and 4 As shown, the automobile bushing of the present invention includes two semicircular steel plates 2 that are butted into a tubular shape as a skeleton, and through holes 3 are opened on the two semicircular steel plates 2 corresponding to each other. In a preferred manner, four through holes 3 are opened on each semicircular steel plate 2, arranged in a rectangular shape; and the thickness of the semicircular steel plate 2 is selected as 3 mm. Such as figure 1 and 2 As shown, the automotive bushing is integrally bonded with rubber 1 vulcanized into a prescribed shape on the inner and outer sides of the semicircular steel plate 2 through the above-mentioned through hole 3 by means of injection or pressing. Such as figure 1 As shown, the shape of the rubber 1 is located on both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com