Composite material of wear-resisting rod piece and preparation method thereof

A technology of composite materials and wear-resistant rods, applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of complex manufacturing process, low production efficiency, thermal shock fatigue, etc., and achieve simple production process, Low investment in equipment and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

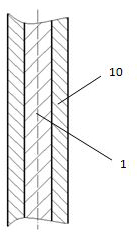

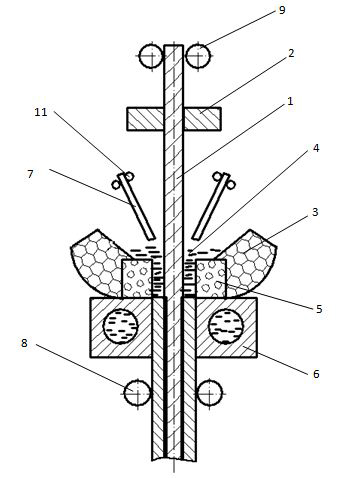

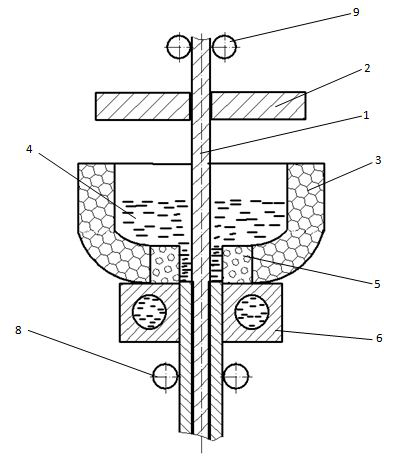

[0051] There are two preparation methods for the above-mentioned wear-resistant rod composite material, method one (see figure 2 ) includes the following steps:

[0052] (1) Choose a cross-sectional area of 3mm 2 ~3000mm 2 The metal rod 1, the length of the metal rod 1 is arbitrarily determined according to needs. Pickling or mechanical methods are used to remove dirt such as rust and oil on the surface of the metal rod 1 .

[0053] The pickling adopts the existing hydrochloric acid or sulfuric acid pickling process, and the mechanical method adopts the existing wire brush derusting process.

[0054] (2) The metal rod 1 prepared in step (1) is vertically inserted into the former 5 at the lower part of the ladle 3 through the guide mechanism 2 and the existing feeding mechanism 9 . The guide mechanism 2 and the drawing mechanism 8 at the lower part of the ladle 3 ensure that the metal rod 1 passes through the center of the former 5, and make the gap between the latter an...

Embodiment 1

[0075] Prepare wear-resistant rod composite materials, the core metal rod 1 is low-alloy steel Q345, the geometric shape of the cross-section is a circle with a diameter of 18mm, the wear-resistant alloy layer 10 is high-chromium alloy cast iron, the thickness is 4mm, and the wear-resistant alloy The alloy composition of layer 10 is designed (mass %): 3.5C, 24.0Cr, 0.25B, 0.7Mn, 0.5Si, 0.8V, S less than 0.035, P less than 0.035, and the rest is Fe. The wear-resistant rod composite material can be used for screening sintered ore and other materials with abrasive wear.

[0076] (1) The cross-sectional diameter is selected to be 18mm (the area is 254.34mm 2 ) bar-shaped Q345 steel with a length of 1.2m. The existing hydrochloric acid pickling process is used to remove dirt such as rust and oil on the surface of the rod-shaped steel, and the metal rod 1 is obtained.

[0077] (2) The metal rod 1 prepared in step (1) is vertically inserted into the former 5 at the lower part of th...

Embodiment 2

[0089] Prepare bimetal wear-resistant rod composite material, the core metal rod 1 is Q235 low-carbon steel, the geometric shape of the cross-section is a circle with a diameter of 6.5mm, the wear-resistant alloy layer 10 is high-chromium alloy cast iron, and the thickness is 2mm. The alloy composition of the wear-resistant alloy layer 10 is designed (mass %): 3.8C, 22.0Cr, 0.5Mn, 0.8Si, 1.2V, 1.2Mo, S less than 0.035, P less than 0.035, and the remainder being Fe.

[0090] (1) The cross-sectional diameter is selected to be 6.5mm (the area is 33.17mm 2 ) rod-shaped Q235 low-carbon steel wire rod with a length of 0.8m. The rust on the surface of Q235 was removed by the existing wire brush derusting process, and the metal rod 1 was obtained.

[0091] (2) The metal rod 1 prepared in step (1) is vertically inserted into the former 5 at the lower part of the ladle 3 through the guide mechanism 2 and the existing feeding mechanism 9 . The guide mechanism 2 and the billet drawing m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com