Earphone cord

A technology for earphone cables and earphones, applied in conductors, multi-core cable end parts, insulated cables, etc., can solve the problems of inability to pass thousands of times, loosening, and broken insulated conductive wires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

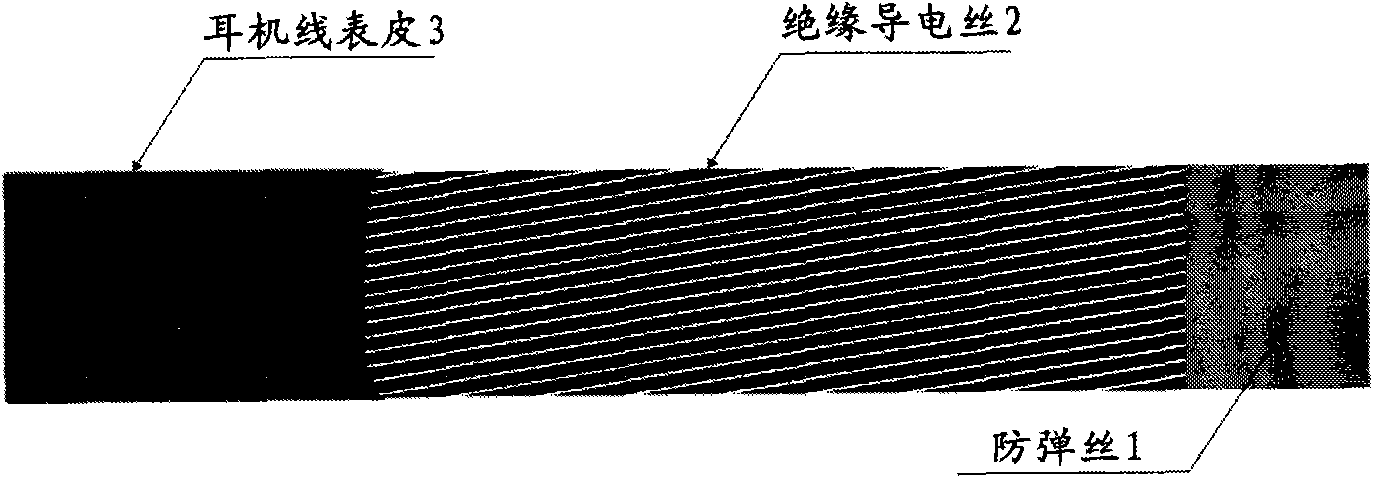

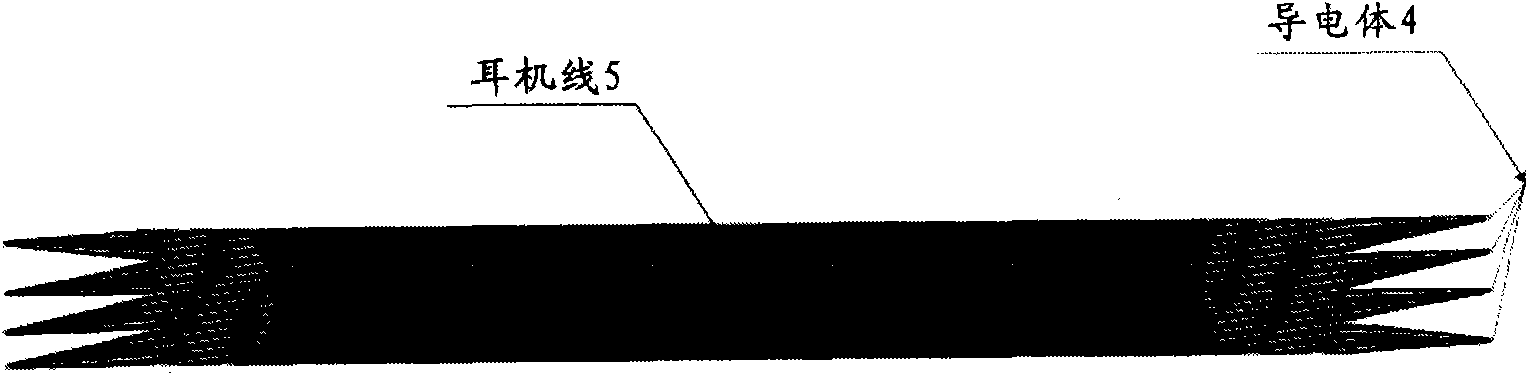

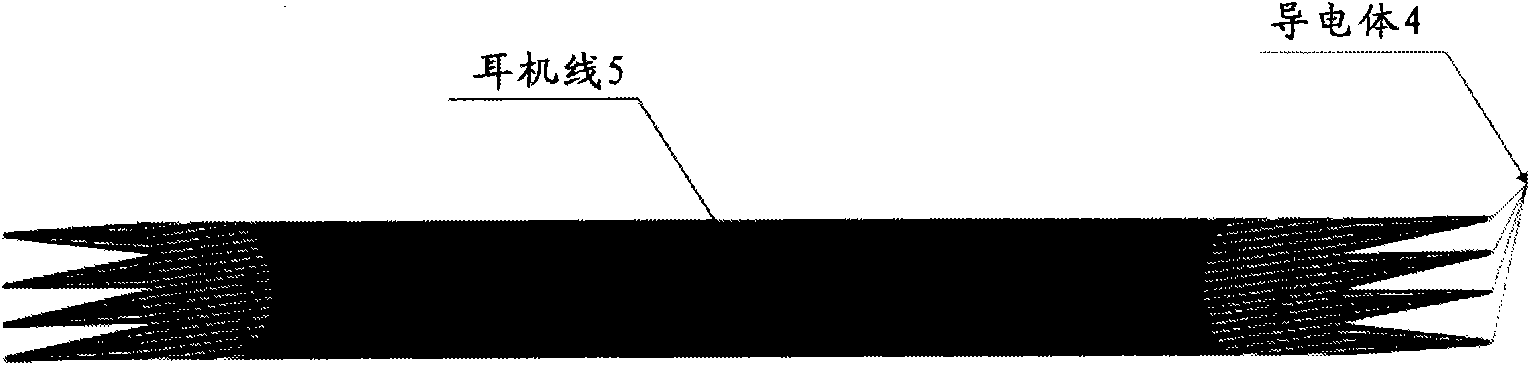

[0017] Such as figure 1 , figure 2 As shown, the novel earphone wire 5 of the present invention includes a bulletproof wire 1 , an insulated conductive wire 2 , a conductor 4 , and an earphone wire skin 3 . The insulated conductive thread 2 is wound on the bulletproof thread 1 in a helical shape, wherein the helical shape means that the insulated conductive thread 2 is at a certain angle to the longitudinal direction of the bulletproof thread 1, so that the insulated conductive thread 2 is not parallel to the longitudinal direction of the bulletproof thread 1, but each The insulated conductive threads are longitudinally parallel, such as figure 1 shown. The earphone wire skin 3 is attached and wrapped on the surface of the insulated conductive wire 2 wound on the bulletproof wire, forming a layer of ultra-thin, soft and wear-resistant skin. The conductor 4 is located at the two ends of the earphone wire 5 that has been cut according to the required length, and is formed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com