Butyl rubber composition, preparation method and method for preparing pressure hose

A technology of butyl rubber and pressure-resistant hoses, which is applied in the direction of hoses, pipes, mechanical equipment, etc., can solve the problems of easy peeling, poor bonding strength, and poor pressure resistance of hoses, and achieve good low temperature resistance and mechanical properties performance, good bonding performance, and the effect of improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

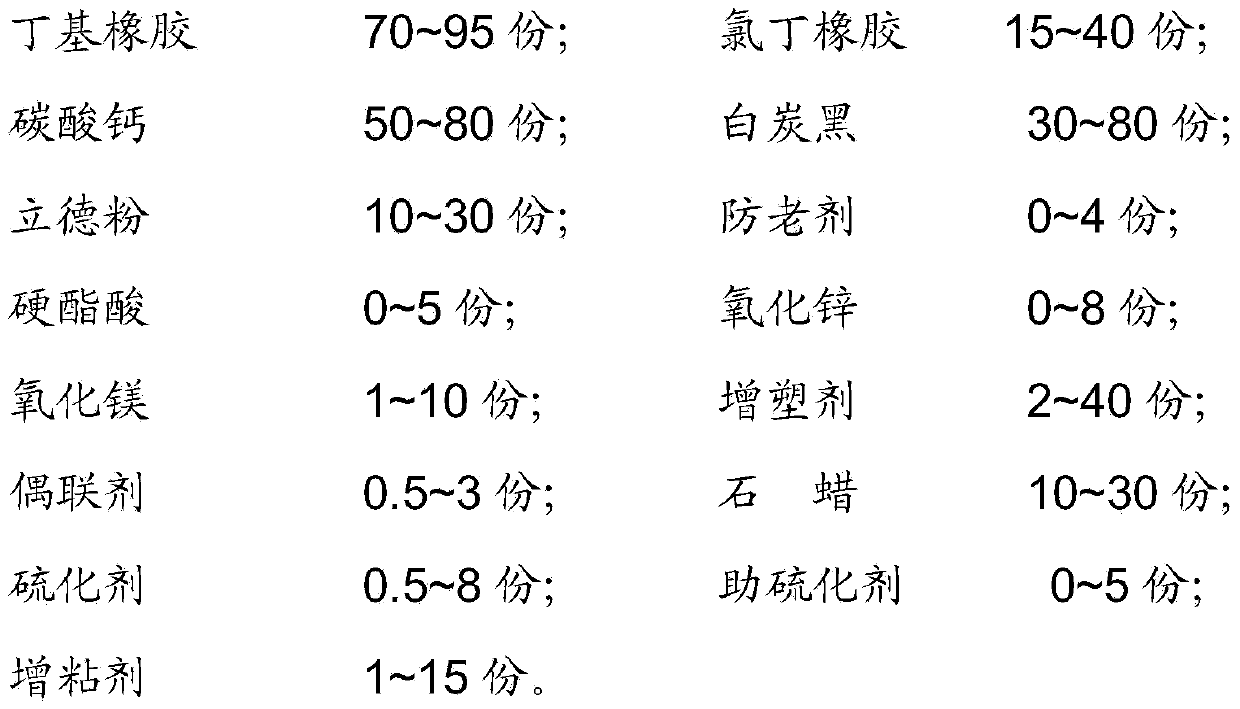

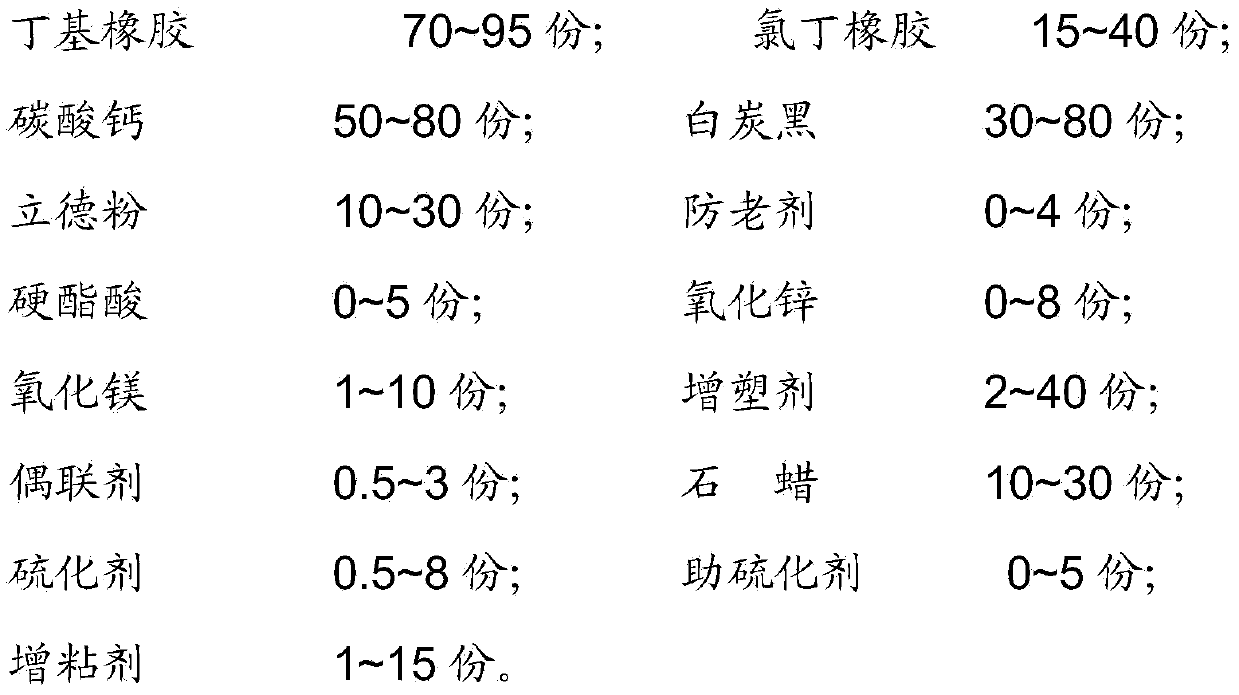

Method used

Image

Examples

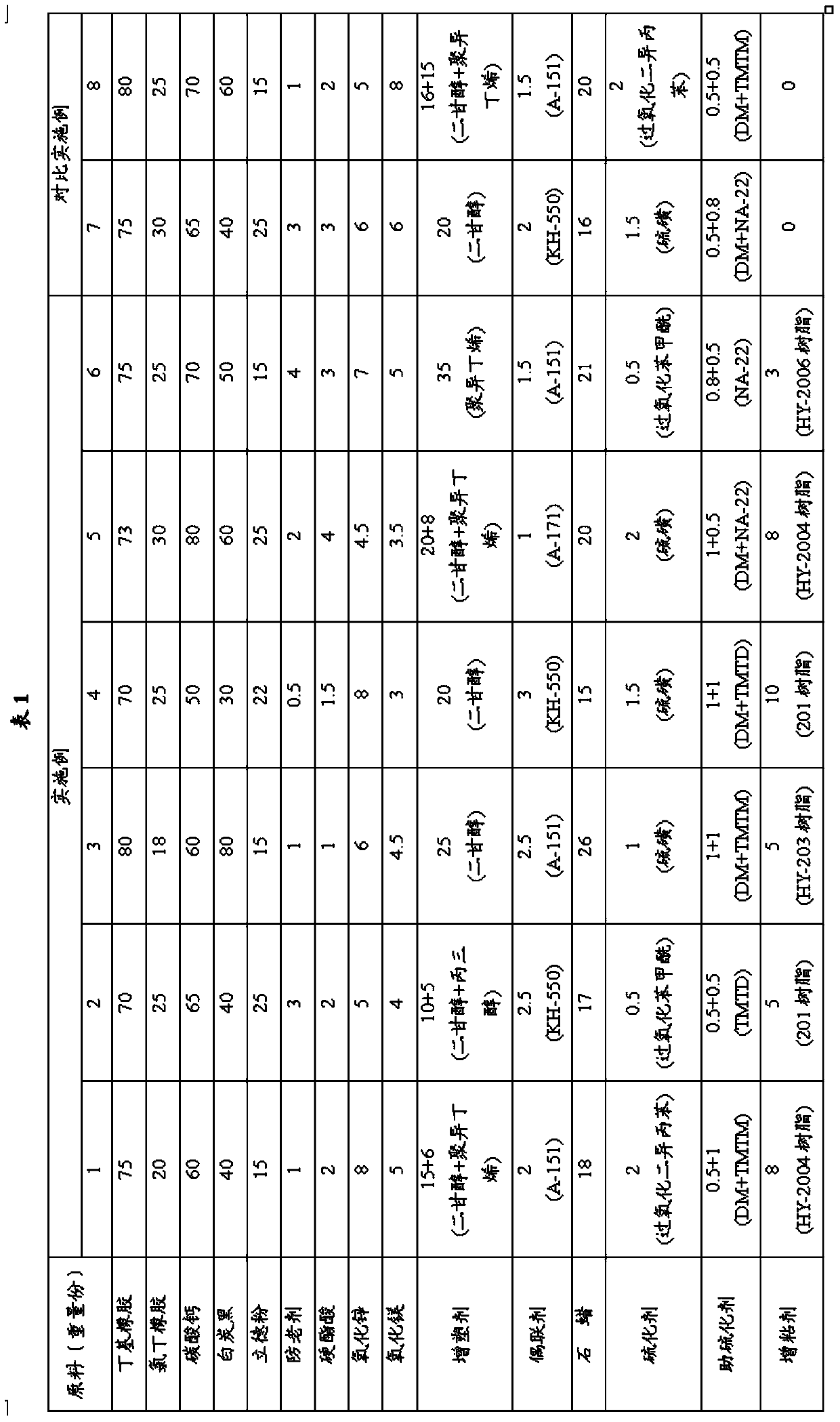

Embodiment 1~6

[0032] According to the mixing ratio in Table 1, use an open mill to mix the rubber materials. First, put the butyl rubber and neoprene raw rubber on the rollers. After the rubber materials are completely covered with the rollers, add calcium carbonate and stearin. Acid and lithopone, mixing 120~300 seconds (embodiment 1~2 mixing 180 seconds; Embodiment 3~4 mixing 210 seconds; Embodiment 5~6 mixing 250 seconds;), mixing time according to adding Whether the compounding agent is mixed or not shall prevail; to adjust the roller distance, white carbon black may be added according to the principle of a small amount of multiple batches, and the mixing time is 120 to 240 seconds (Examples 1 to 2 are mixed for 180 seconds; Examples 3 to 4 are mixed Refining for 150 seconds; Example 5-6 mixing for 200 seconds;); then add magnesium oxide, zinc oxide, anti-aging agent, and plasticizer (half of the total mass), and mix for 120-360 seconds according to the dispersed state of the compounding...

Embodiment 1

[0039] The hardness of the vulcanized rubber of the lining rubber butyl rubber composition is 55, the tensile strength is 6.6MPa, the elongation at break is 701%, and the brittle temperature reaches -50°C;

[0040] The T-peel strength of the braided jacket and the rubber lining is 9.36N cm;

[0041] The hydraulic burst pressure of the pressure hose is 4.12MPa.

Embodiment 2

[0043] The hardness of the vulcanized rubber of the lining rubber butyl rubber composition is 48, the tensile strength is 5.7MPa, the elongation at break is 721%, and the brittle temperature reaches -40°C;

[0044] The T-peel strength of the braided jacket and the rubber lining is 3.70N cm;

[0045] The hydraulic burst pressure of the pressure hose is 3.28MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com