Articles with dispersed conductive coatings

a technology of conductive coating and dispersed conductive material, which is applied in the field of articles, can solve the problems of deterioration of the transparency of the anti-electrostatic layer, carbon fibers not well dispersed, and carbon fibers, so as to reduce the amount of ultra fine conductive fibers, improve the transparency, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

[0059] The multi-layered carbon nanotube (product of Tsinghua-Nafine Nano-Powder Commercialization Engineering Center, with the average outer diameter of 10 nm) and tertiary amine modified alkyl co-polymer as the disperser are added to and equally dispersed in ethanol solvent. This coating solution is prepared such that it has 0.007 weight % of the multi-layered carbon nanotube and the 0.155 weight % of the disperser.

[0060] This coating solution is applied to the surface of a polycarbonate plate, which is a product of Takiron Co. Ltd., with the thickness of 3 mm, the light transmission of 90.2%, and the haze of 0.40%. The transparent conductive polycarbonate resin plate with the conductive layer of the thickness of 29 nm and the estimated content of the multi-layered carbon nanotube of 2.5 mg / m2 is obtained after the solution is dried. The surface resistivity and the light transmission of the conductive layer of the resin plate are measured by the same way as that of the example 1....

example 3

[0061] 1.7 weight % of the powdered vinylchloride resin as the binder is solved into cyclohexanon solvent. The single-layered carbon nanotube (product of Carbon Nano Technology, with the diameter of 0.7-2 nm) and alkylammonate solution of acid polymer, as a disperser are added to and equally dispersed in the solution. This coating solution has 0.3 weight % of single-layered carbon nanotube and 0.18 weight % of disperser. This coating solution is applied to and dried on the surface of acryl film with the thickness of 100 μm, acquiring the conductive laminate film. The transparent conductive vinylchloride resin plate is obtained by pressing the laminate film described above to the vinylchloride resin plate with the thickness of 3 mm in the temperature of 160° C. with the pressure of 30 Kg / cm2.

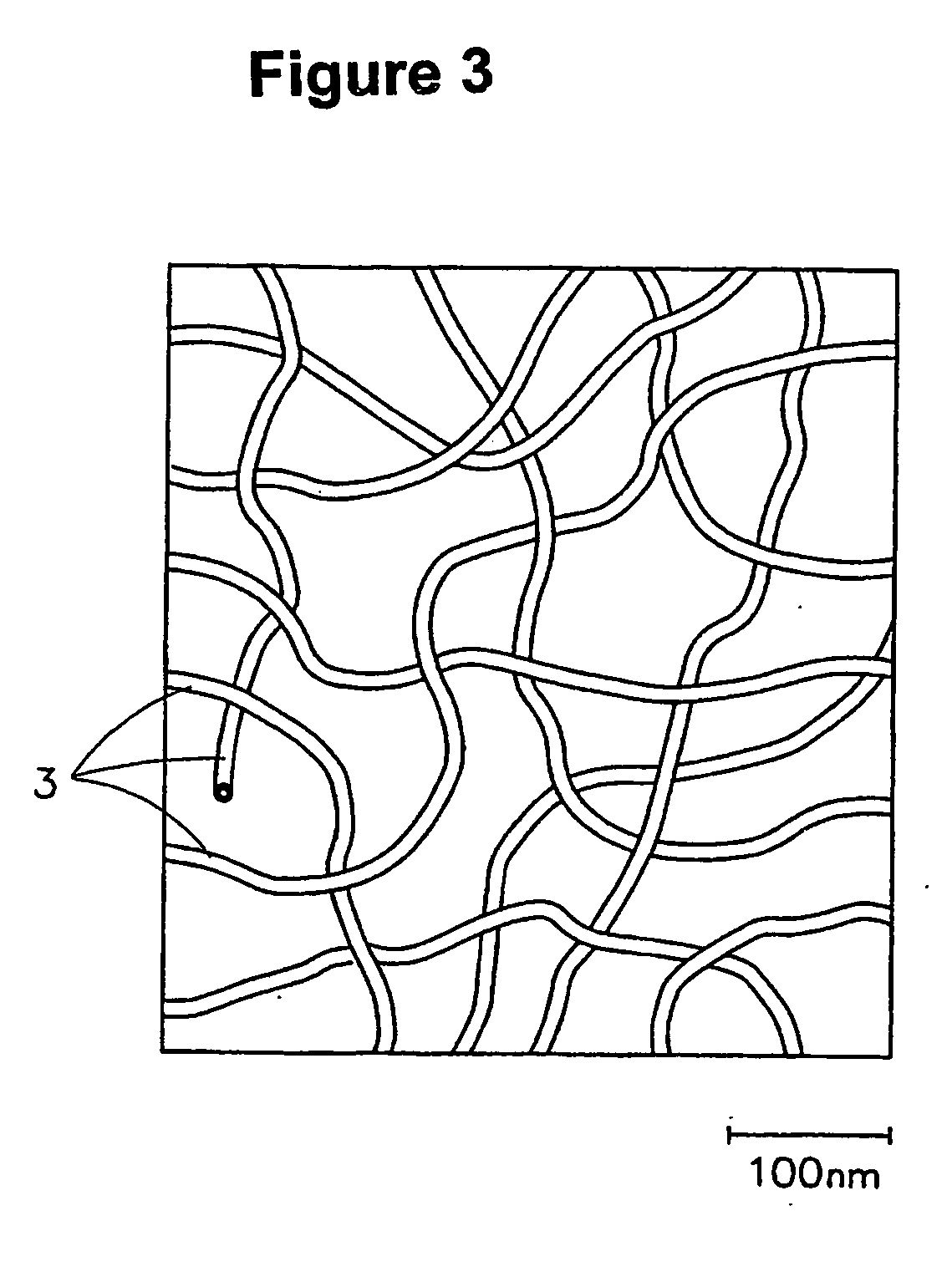

[0062] The conductive layer of this resin plate is observed by a transmission electron microscopy (a product of Nihon Denshi Kogyo Corp., JEM-2010), measuring the area ratio of the single-layere...

example 4

[0064] The coating solution is prepared by the following procedure. Single-layered Carbon nanotube (synthesized by referring to Chemical Physics Letters, 323 (2000) P 580-585, with the diameter of 1.3-1.8 nm) and the co-polymer between poly oxy-ethylene and poly oxy-propylene as the disperser are added to and dispersed in the mixture of isopropylene alcohol and water (with the compound ratio of 3:1) as a solvent. This coating solution is prepared such that it has 0.003 weight % of single-layered carbon nanotube and 0.05 weight % of disperser. This coating solution is applied to the surface of a polyethyleneterephtalate film with the thickness of 100 μm (with the light transmission of 94.5%, and the haze of 1.5%). After drying the solution, the film is coated with the urethane acrylate solution diluted to 1-600th with methyl isobutyl ketone, and then dried. The transparent conductive polyethyleneterephtalate film is obtained.

[0065] The conductive layer of the film is observed by a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| light transmittance | aaaaa | aaaaa |

| light transmittance | aaaaa | aaaaa |

| light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com