Titanium alloy artificial knee joint magnetorheological polishing device

An artificial knee joint and magnetorheological polishing technology, which is applied in the field of magnetorheological polishing processing devices for titanium alloy artificial knee joints, can solve the problems of easy wear and passivation of grinding wheels, low production efficiency, grinding micro-cracks, etc., and achieves environmental friendliness. , the effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below with reference to the accompanying drawings and embodiments.

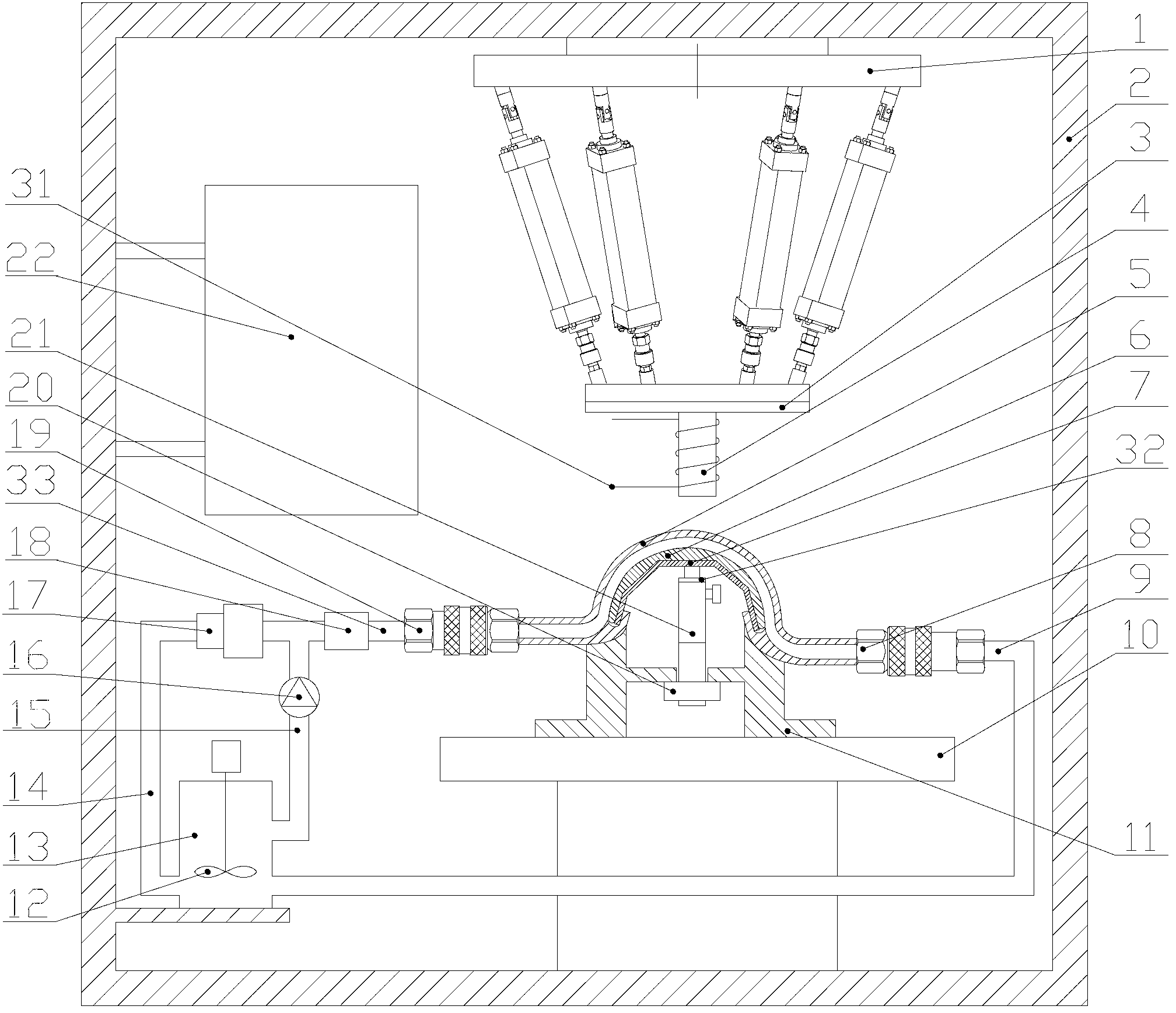

[0044] figure 1 It is a cross-sectional structural diagram of a magnetorheological polishing processing device for a titanium alloy artificial knee joint, which shows each component of the magnetorheological polishing processing device for a titanium alloy artificial knee joint. Depend on figure 1 It can be seen that the liquid storage tank 13 is fixed on the frame 2, wherein a stirrer 12 is installed in the liquid storage tank 13 to ensure uniform mixing of abrasive particles and magnetic particles in the magnetic fluid. An infusion pipeline 15 is opened in the upper part of the liquid storage tank 13, and a delivery pump 16 is installed on the infusion pipeline 15, so that the delivery pump 16 can deliver the magnetic fluid in the liquid storage tank 13 at a certain pressure. The other end of the infusion pipeline 15 is divided into two branches, name...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com