Mirror polishing machine

A polishing machine, frame technology, used in surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

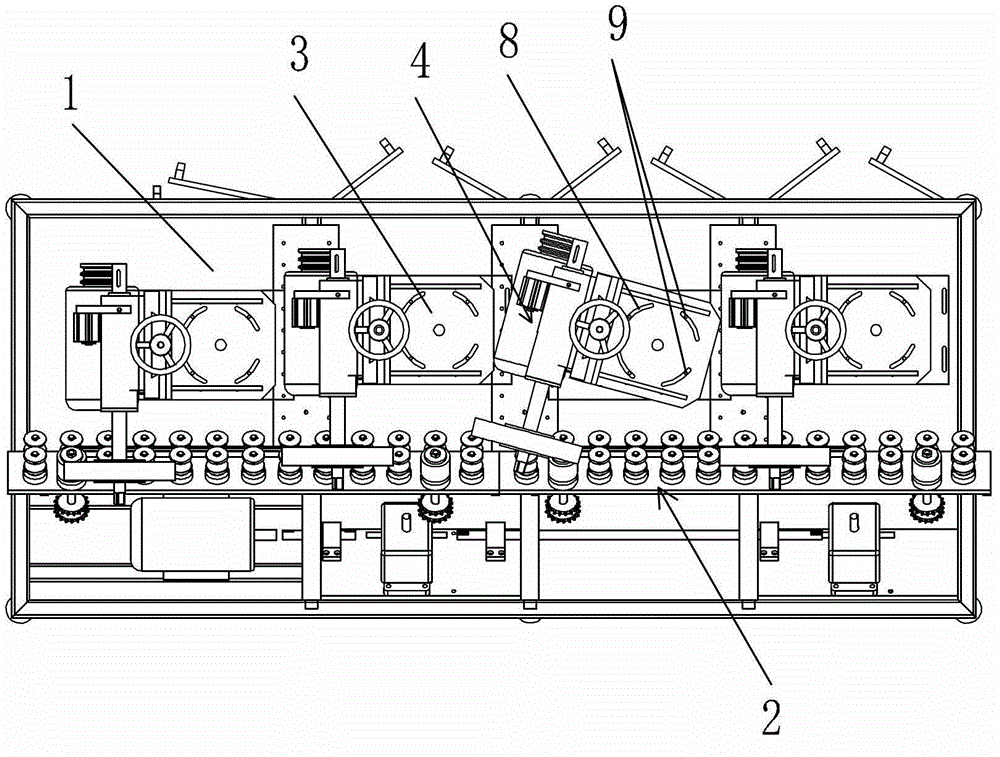

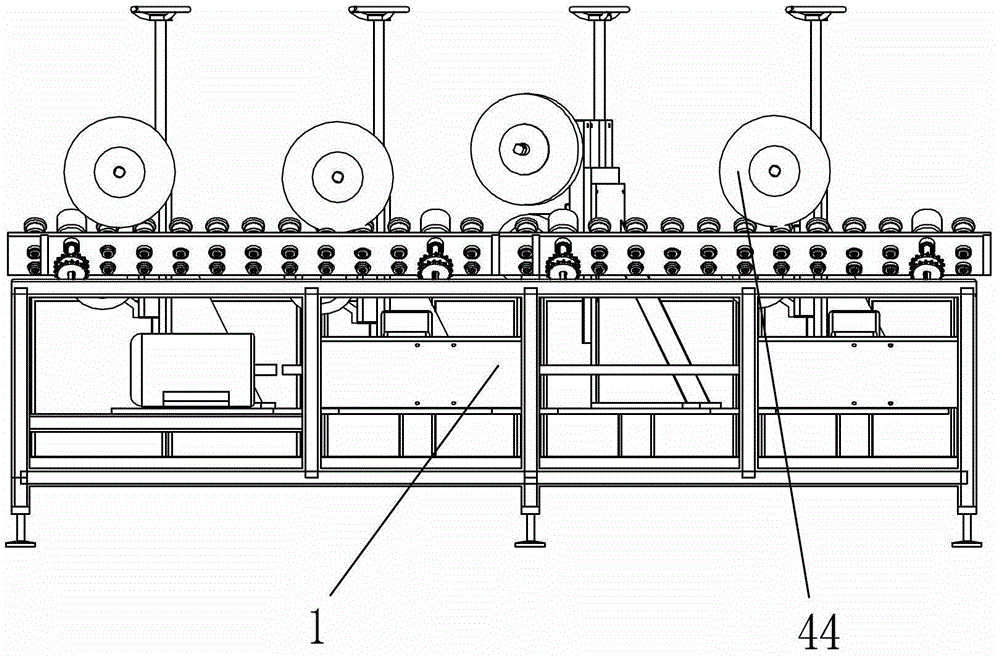

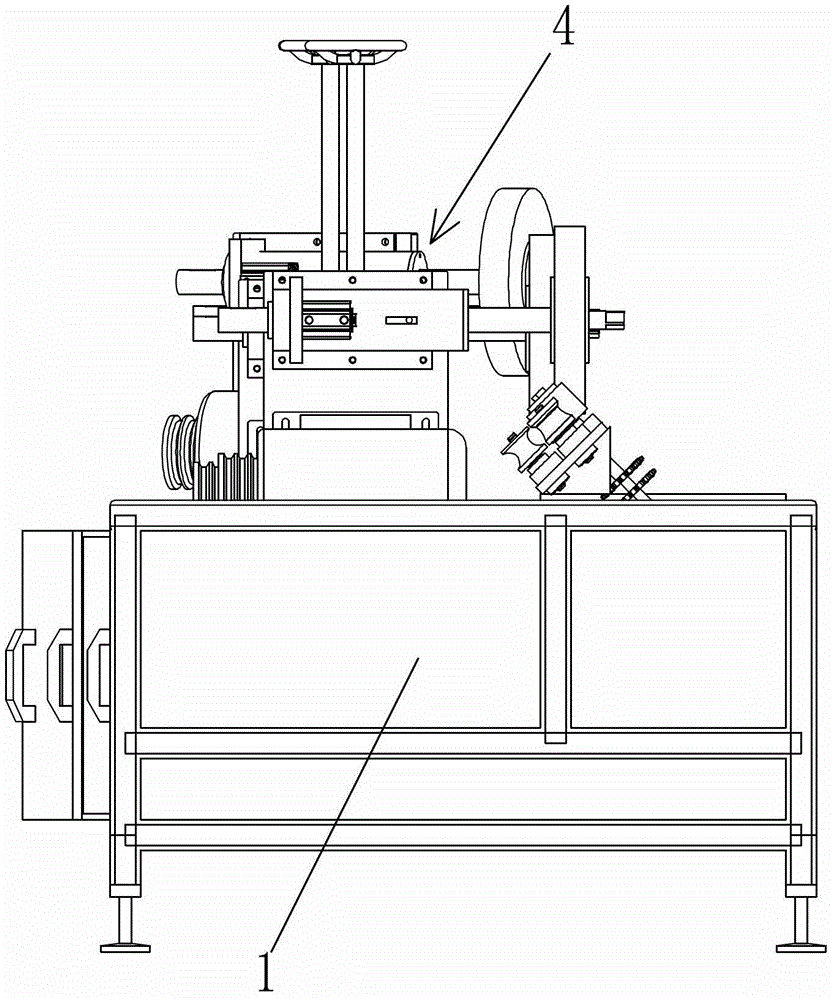

[0018] As shown in the figure, the mirror polishing machine includes a frame 1, on which a conveying mechanism 2 capable of conveying special-shaped pipes is provided, and on the frame 1, a grinding device for polishing special-shaped pipes is also provided. A mounting base 3 is included, and a polishing assembly 4 is arranged on the mounting base 3 . The frame 1 is provided with a rotation adjustment structure that can adjust the rotation of the mounting base 3 . A vertical adjustment structure that can adjust the upward and downward movement of the polishing assembly 4 is provided on the mounting base 3 . The conveying mechanism 2 includes multiple sets of guide wheels arranged on the frame 1, and a sprocket wheel is arranged at the bottom of the frame 1 to drive each set of guide wheels to rotate, so as to achieve the purpose of conveying the special-shaped pipe.

[0019] Specifically, the polishing assembly 4 includes a mounting plate 41 on which a motor 42 and a rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com