Mobile phone shell polishing device

A technology of polishing device and mobile phone case, which is applied to grinding/polishing equipment, grinding workpiece support, grinding machine, etc., can solve the problems of high cost, low polishing efficiency, limiting production efficiency of mobile phone case, etc., and achieve the effect of improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] to combine Figure 1 to Figure 7 , the present invention is further described:

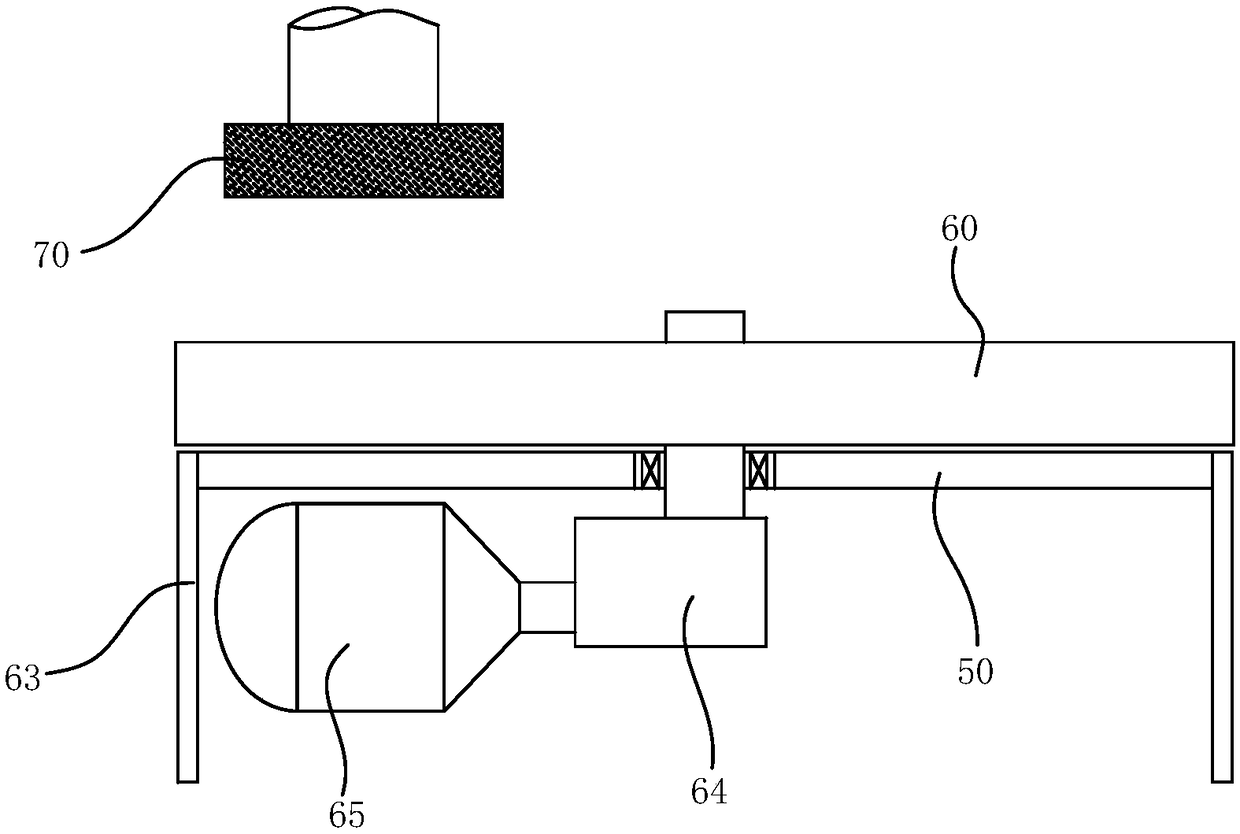

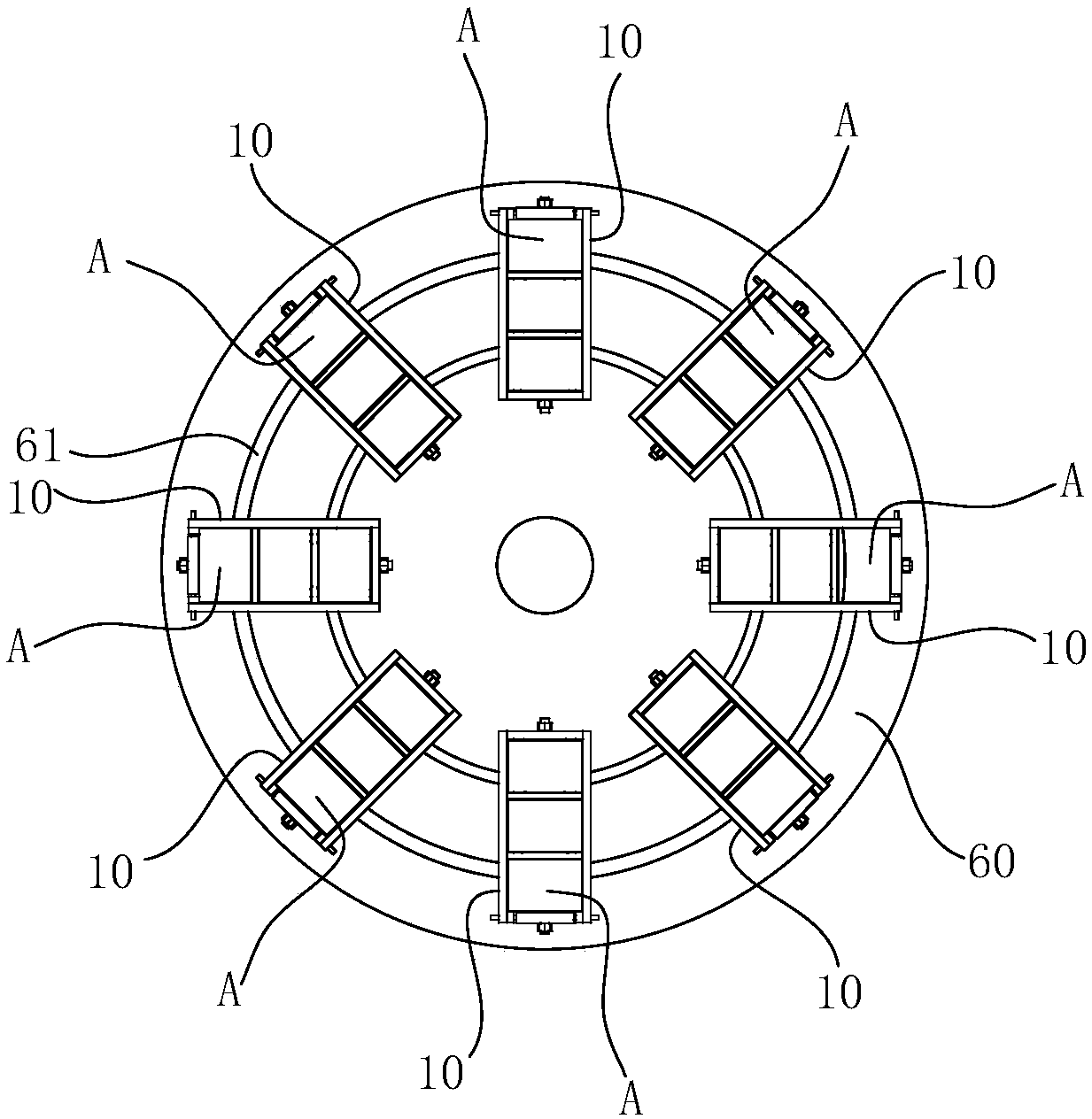

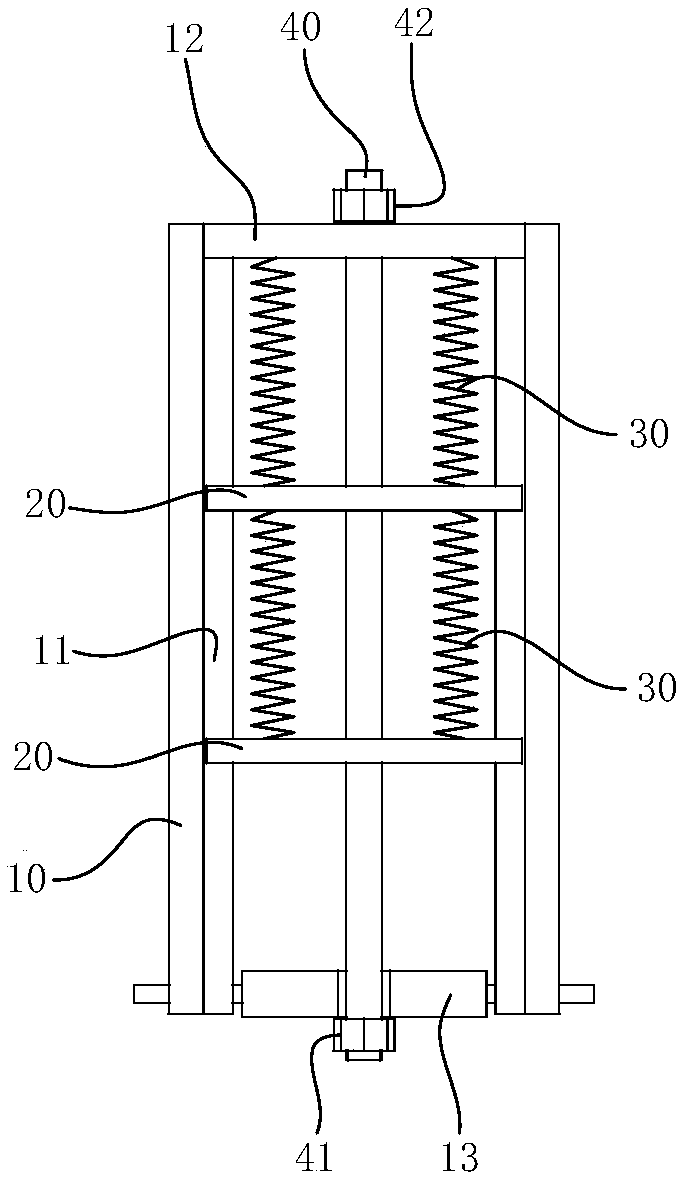

[0015] The mobile phone shell polishing device includes a workbench 50, on which a chuck 60 is rotatably arranged, the disk surface of the chuck 60 is horizontal, and the drive mechanism drives the chuck 60 to rotate around the axis, and the chuck 60 The upper disk surface is provided with an annular clamping groove 61, the annular clamping groove 61 is concentric with the chuck 60, and the clamp is arranged on the circular clamping groove 61, and a plurality of clamps are arranged at intervals along the annular clamping groove 61. The top of the disk 60 is rotated with a polishing disk 70. The fixture includes a rectangular box body 10, and a clamping plate 20 is slidably arranged in the box opening of the rectangular box body 10. The plate surface of the clamping plate 20 is vertical and along the The longitudinal direction of the rectangular box body 10 is provided with a plurality of i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com