Water based environmental barrier coatings for high temperature ceramic components

a technology of ceramic components and environmental barriers, applied in water-setting substances, blade accessories, machines/engines, etc., can solve the problems of unsatisfactory effects, inability to stabilize silicon oxide in high-temperature steam, and increased durability of high-temperature engine components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

Example 1

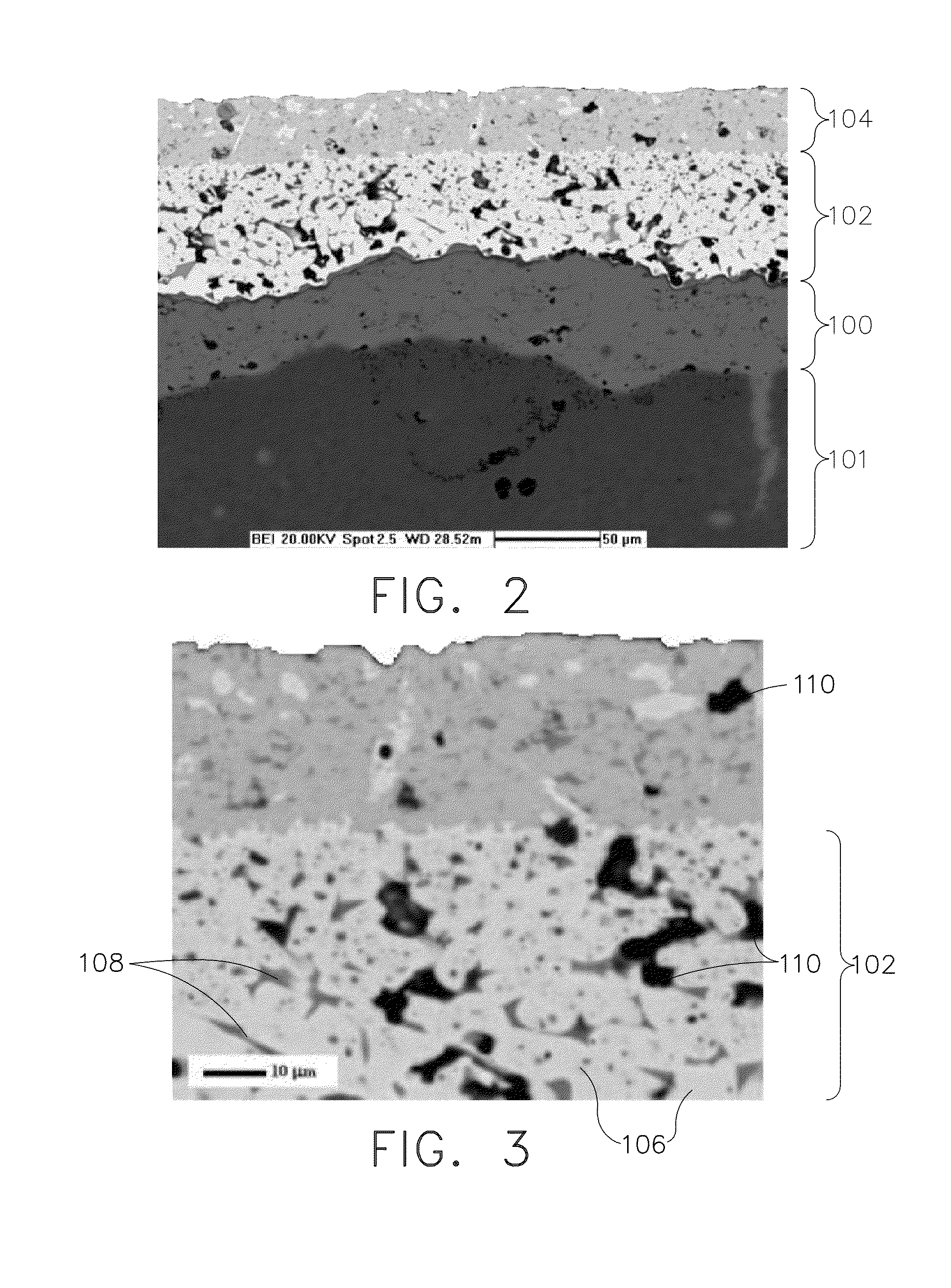

[0081]A silicon bond coat was applied to a SiC—SiC CMC using a conventional air plasma spray process. Next, a primary transition material slurry was made by first mixing yttrium disilicate powder, aluminum oxide powder, water, polyacrylic acid-polyethylene oxide copolymer, Surfynol 502®, and glycerin in a plastic container, along with enough 0.25 inch (6.35 mm) diameter, cylindrical alumina media to line the bottom of container. This mixture was placed on a roller mill for 15 hours. After taking the container off of the roller mill, the alumina media was removed. Xanthan gum was then added and the mixture was shaken for 15 minutes using a paint shaker. Finally, Rhoplex® HA8 emulsion was added and the container was placed back onto the roller mill for 1 hour (without media).

[0082]The resulting primary transition material slurry (Slurry A) consisted of 65.87% yttrium disilicate (primary transition material), 4.85% aluminum oxide (sintering aid), 6.59% polyacrylic acid-polyeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| operating temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com