Resource-saving type high-boron high-speed steel composite roll and manufacturing method thereof

A composite roll and high-speed steel technology, which is applied to high-speed steel rolls and their preparation, resource-saving high-boron high-speed steel composite rolls and their preparation fields, can solve the problems of a large amount of precious alloys added to the rolls, low roll performance and high manufacturing costs. , to achieve the effect of excellent wear resistance, low cost and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

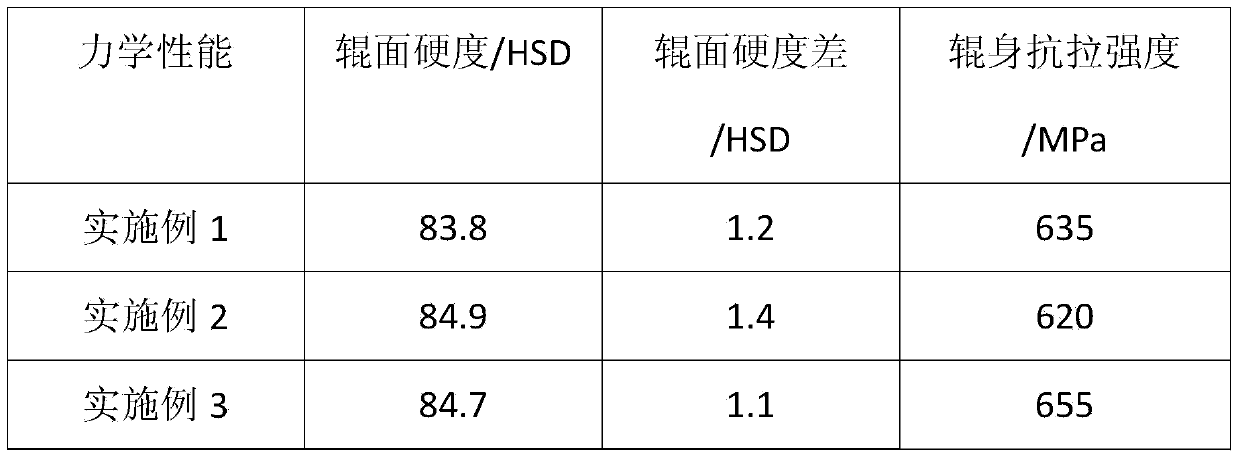

Embodiment 1

[0030] The resource-saving high-boron high-speed steel composite roll of the present invention (roll body length 600mm, roll body diameter 320mm) is composed of three parts: outer layer high-boron high-speed steel, intermediate transition layer graphite steel and roll core hot-rolled medium carbon round steel. High-layer boron high-speed steel and intermediate transition layer graphite steel are smelted in 1000 kg and 500 kg intermediate frequency induction furnaces respectively, and composited by a horizontal centrifuge, while transition layer graphite steel and roll core hot-rolled medium carbon round steel are composited by hot charging made. Its specific preparation process is:

[0031] ①Use scrap steel and high-chromium cast iron roll waste in the electric furnace first (the chemical composition and mass fraction of high-chromium cast iron roll waste are: 2.30~3.30%C, 0.30~1.00%Si, 0.50~1.20%Mn, P≤0.10% , S≤0.05%, 0.70~1.70%Ni, 18.01~22.00%Cr, 1.51~3.00%Mo, 0.00~0.60%V, ...

Embodiment 2

[0035] The resource-saving high-boron high-speed steel composite roll of the present invention (the length of the roll body is 600mm, and the diameter of the roll body is 350mm) is composed of three parts: high-boron high-speed steel in the outer layer, graphite steel in the middle transition layer, and hot-rolled medium carbon round steel in the roll core. High-layer boron high-speed steel and intermediate transition layer graphite steel are smelted in 1000 kg and 500 kg intermediate frequency induction furnaces respectively, and composited by a horizontal centrifuge, while transition layer graphite steel and roll core hot-rolled medium carbon round steel are composited by hot charging made. Its specific preparation process is:

[0036]①Use scrap steel and high-chromium cast iron roll waste in the electric furnace first (the chemical composition and mass fraction of high-chromium cast iron roll waste are: 2.30~3.30%C, 0.30~1.00%Si, 0.50~1.20%Mn, P≤0.10% , S≤0.05%, 0.70~1.70%...

Embodiment 3

[0040] The resource-saving high-boron high-speed steel composite roll of the present invention (roll body length 650mm, roll body diameter 380mm) is composed of three parts: outer layer high-boron high-speed steel, intermediate transition layer graphite steel and roll core hot-rolled medium carbon round steel. High-layer boron high-speed steel and intermediate transition layer graphite steel are smelted in 1000 kg and 500 kg intermediate frequency induction furnaces respectively, and composited by a horizontal centrifuge, while transition layer graphite steel and roll core hot-rolled medium carbon round steel are composited by hot charging made. Its specific preparation process is:

[0041] ①Use scrap steel and high-chromium cast iron roll waste in the electric furnace first (the chemical composition and mass fraction of high-chromium cast iron roll waste are: 2.30~3.30%C, 0.30~1.00%Si, 0.50~1.20%Mn, P≤0.10% , S≤0.05%, 0.70~1.70%Ni, 18.01~22.00%Cr, 1.51~3.00%Mo, 0.00~0.60%V, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com