Eccentric sleeve mechanism for cone crusher

A technology of cone crusher and eccentric sleeve, applied in grain processing and other directions, can solve the problems of reducing the working efficiency and production capacity of the cone crusher, large wear of the eccentric copper sleeve and the main shaft of the moving cone, and increasing the use cost of the machine, so as to provide crushing Efficiency and yield, increased service life, reduced equipment operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

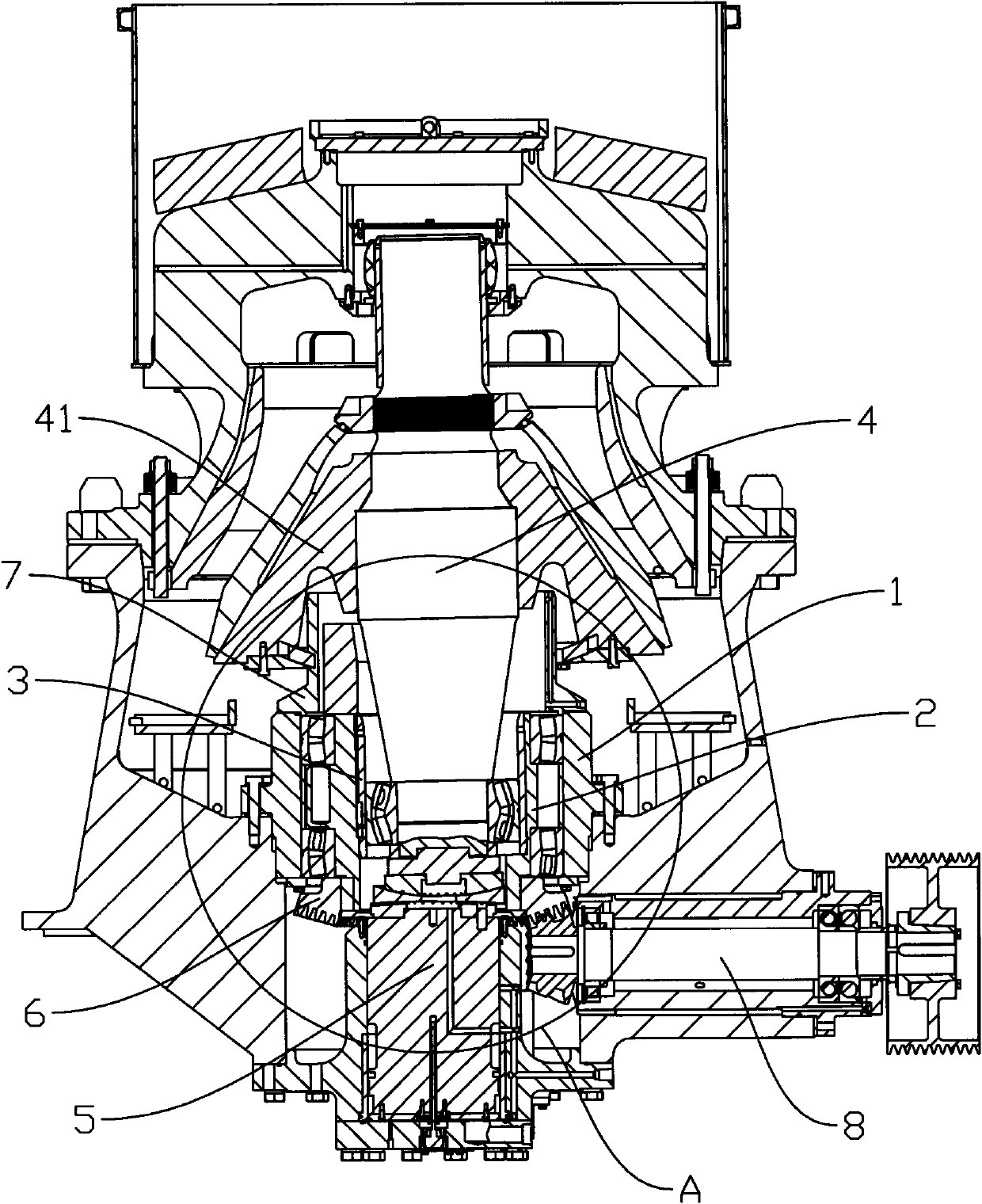

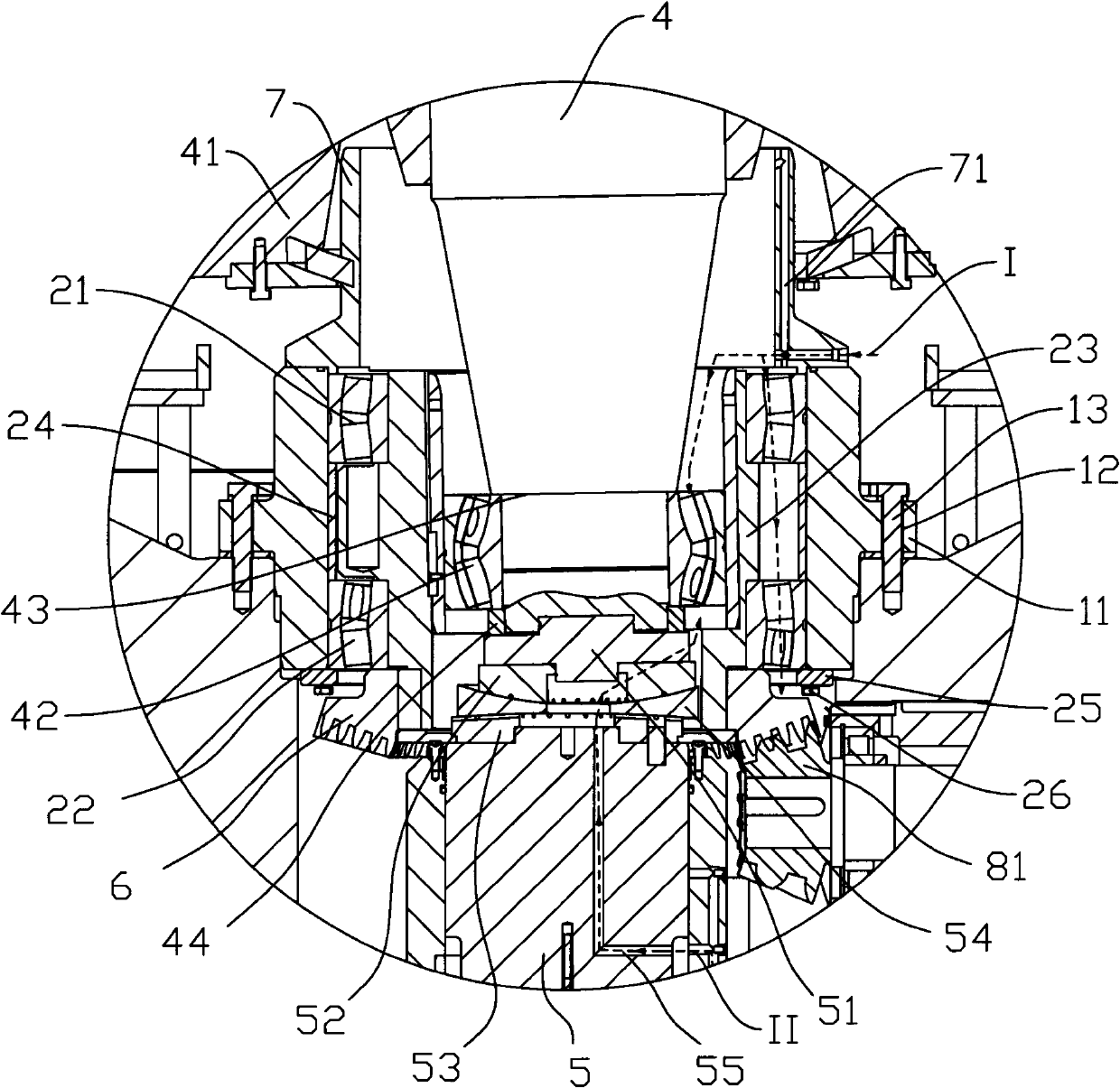

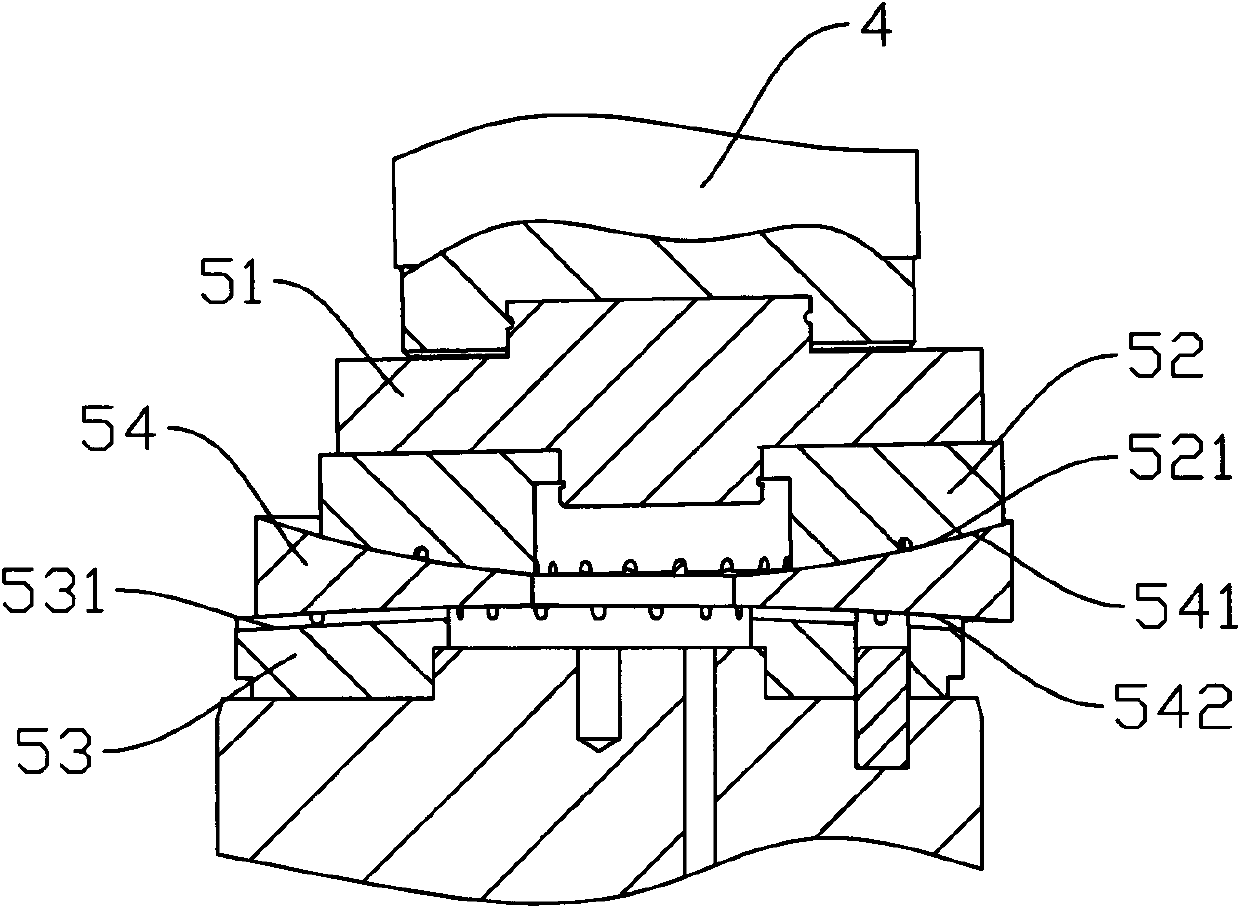

[0019] Such as figure 1 , 2 Figure 3 shows a schematic structural view of an embodiment of the present invention. An eccentric sleeve mechanism for a cone crusher includes a central sleeve 1 arranged on the frame. The outer wall of the central sleeve is horizontally provided with mounting ears 11, The ears are provided with mounting holes 12, the central sleeve is fixed on the frame through the mounting holes by bolts 13, the central sleeve is provided with an eccentric sleeve 2, and a bearing assembly I is provided between the eccentric sleeve and the central sleeve. The eccentric bushing is provided with an eccentric bushing 3, the moving cone main shaft 4 of the cone crusher passes through the eccentric bushing and is pressed on the support base 5. The support base is provided with a lubrication channel II55, between the eccentric bushing and the moving cone main shaft Bearing assembly II, the lower end of the eccentric sleeve is provided with a gear 6 that meshes with the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com