Orthogonal double-pendulum shaft calibrating and debugging method as well as reflector assembling and adjusting method for laser processing

A technology of laser processing and calibration method, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of complex calibration method, and achieve the effect of high measurement accuracy, convenient implementation and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

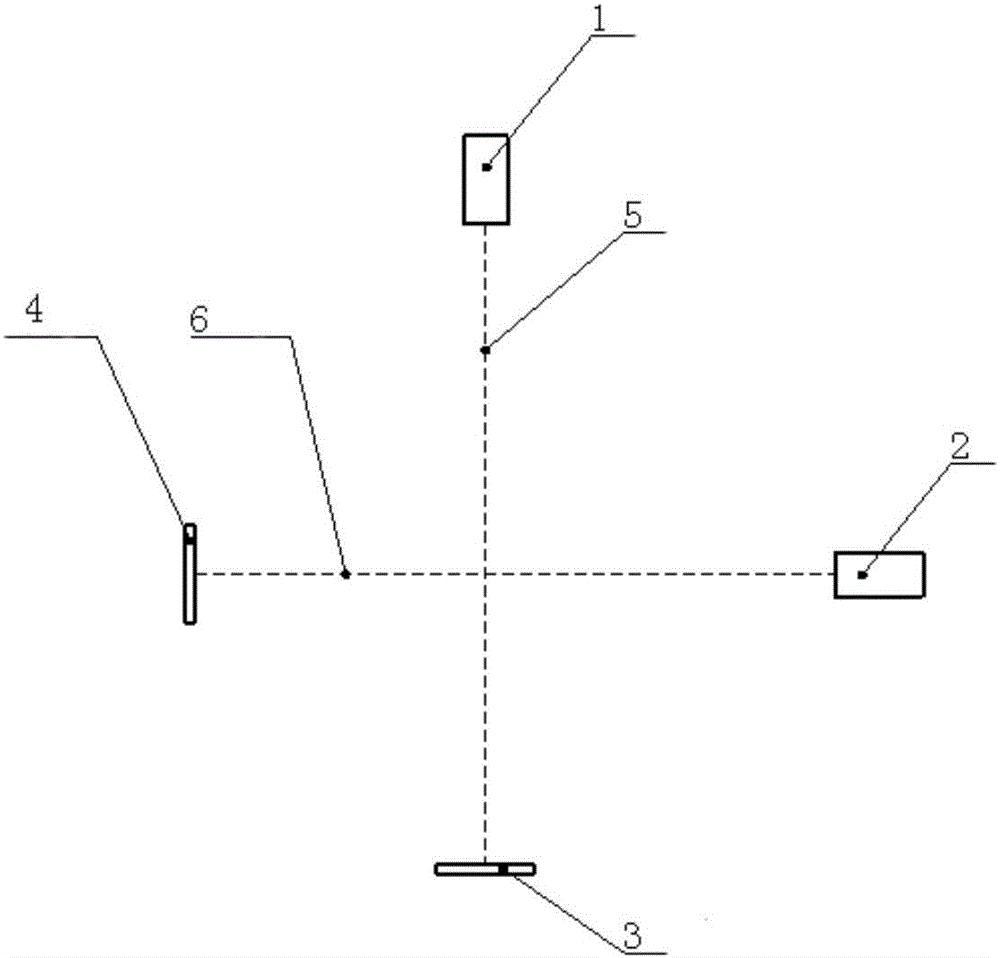

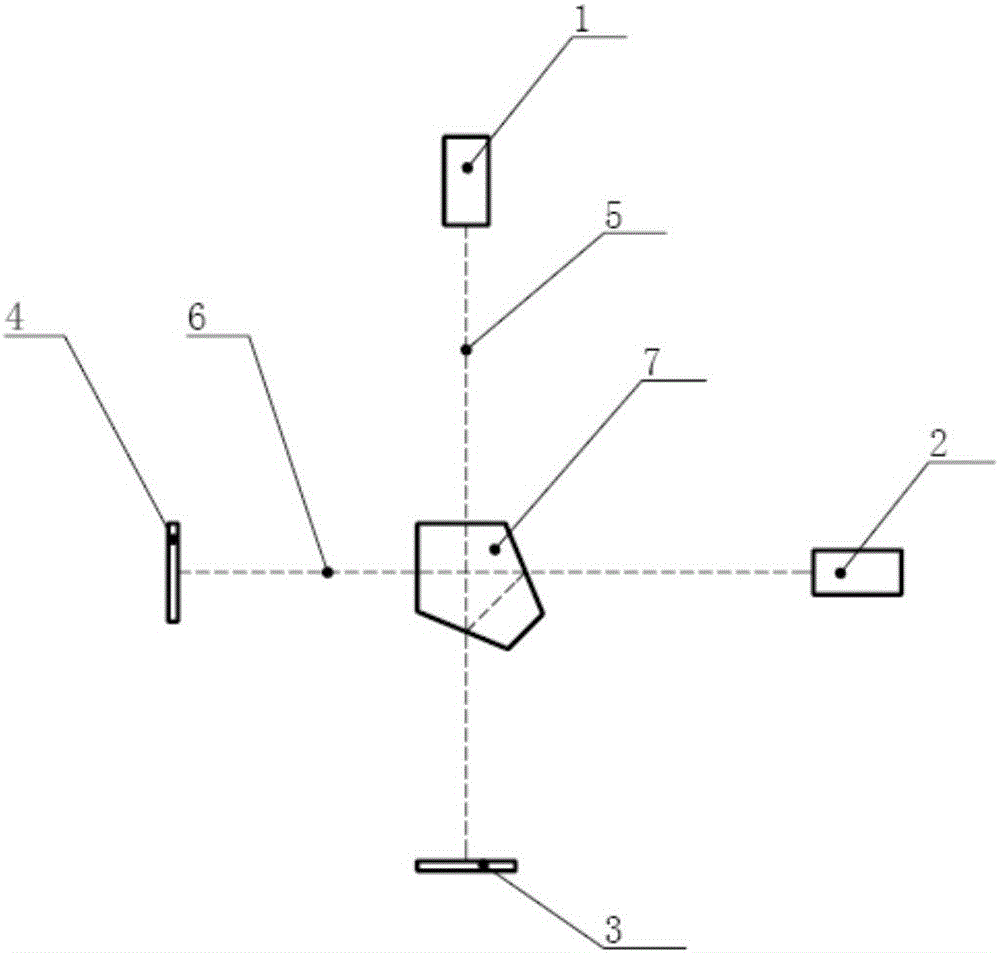

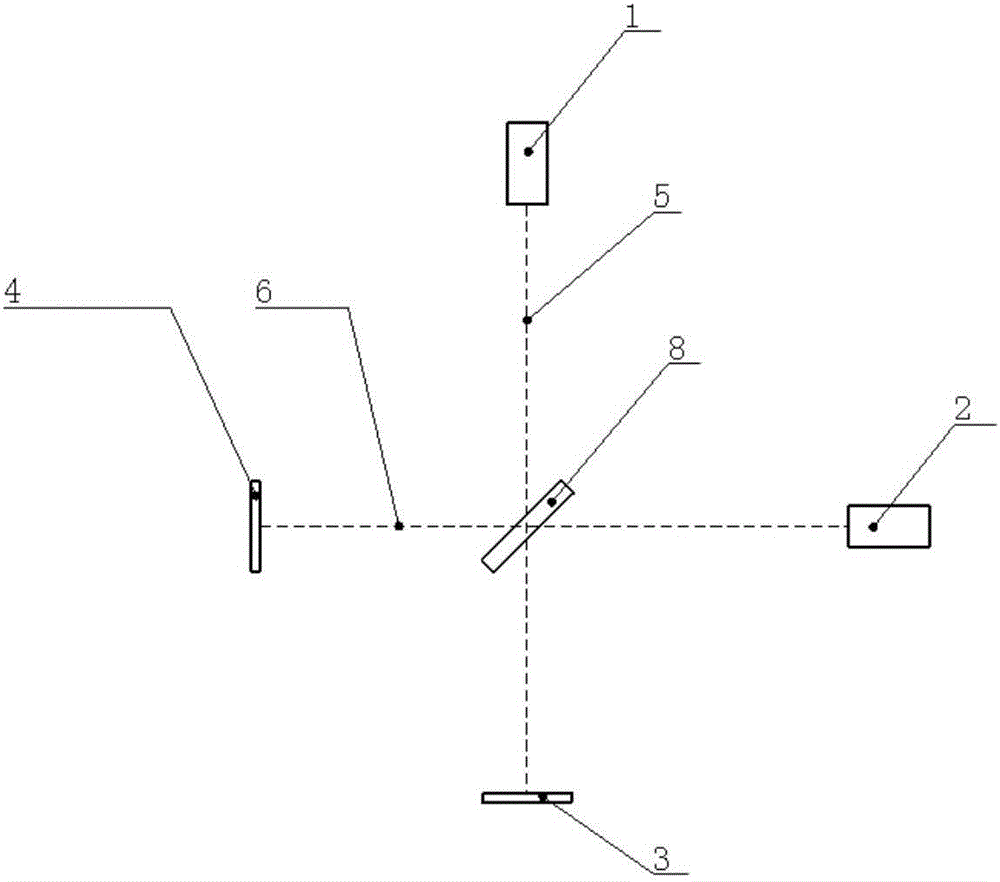

[0034] Such as figure 1 and figure 2 As shown, the method for calibrating orthogonal double pendulum axes applied to laser processing provided by the present invention is used to calibrate the quadrature error of the first pendulum axis and the second pendulum axis 5, and the method includes the following steps:

[0035] 1) Plane reflector 1 and autocollimator 1 are respectively arranged at both ends of the first pendulum axis, and the positions of plane reflector 1 and autocollimator 1 are adjusted so that the mirror surface of plane reflector 1 is aligned with the first pendulum The axis is vertical, so that the outgoing beam of the autocollimator 1 is parallel to the rotation axis of the first pendulum shaft; the rotation accuracy Δδ of the first pendulum shaft is measured by the autocollimator 12 1 .

[0036] 2) Plane reflector 2 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com