Levelling and horizontal error testing device

A level error and equipment technology, which is applied in the field of leveling and level error testing equipment, can solve problems such as insufficient stability, unstable autocollimator data, accuracy of test data, poor consistency, etc., to achieve a fast zero position The effect of fast calibration and optical alignment and stable test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

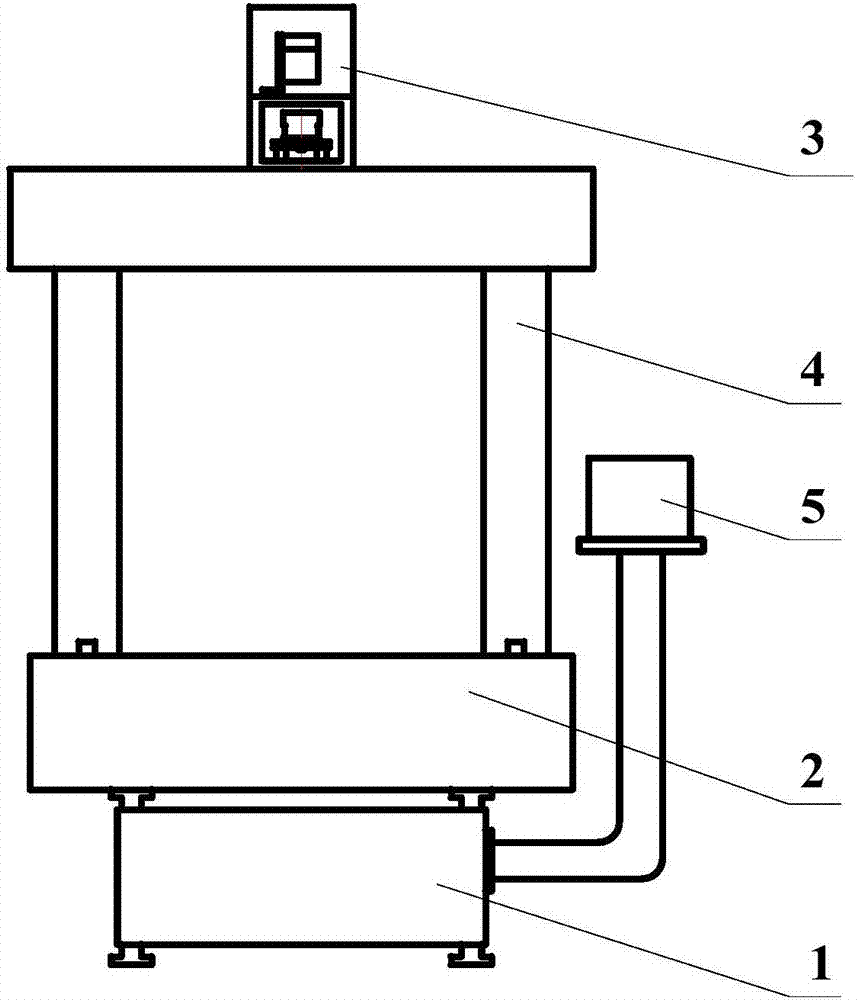

[0047] The overall structure of the present invention is as follows figure 1 As shown, it includes a base 1, a granite plate 2, a leveling and aiming device 3, a transmission system 4, and an electric control box 5;

[0048] The four corners of the base 1 are provided with horizontal adjustment pads, and the granite plate 2 is installed on the horizontal adjustment pad of the base 1. The granite plate 2 is adjusted to be in a horizontal position through the horizontal adjustment pad, and the granite plate 2 is used to place the product to be leveled. . Horizontal sliding guide rails are installed on the upper surface of the granite slab 2;

[0049] The transmission system 4 is a gantry bracket, the two support arms are connected to the horizontal sliding rails of the granite slab 2 , and the electric control box 5 controls the transmission system 4 to move on the horizontal sliding rails of the granite slab 2 .

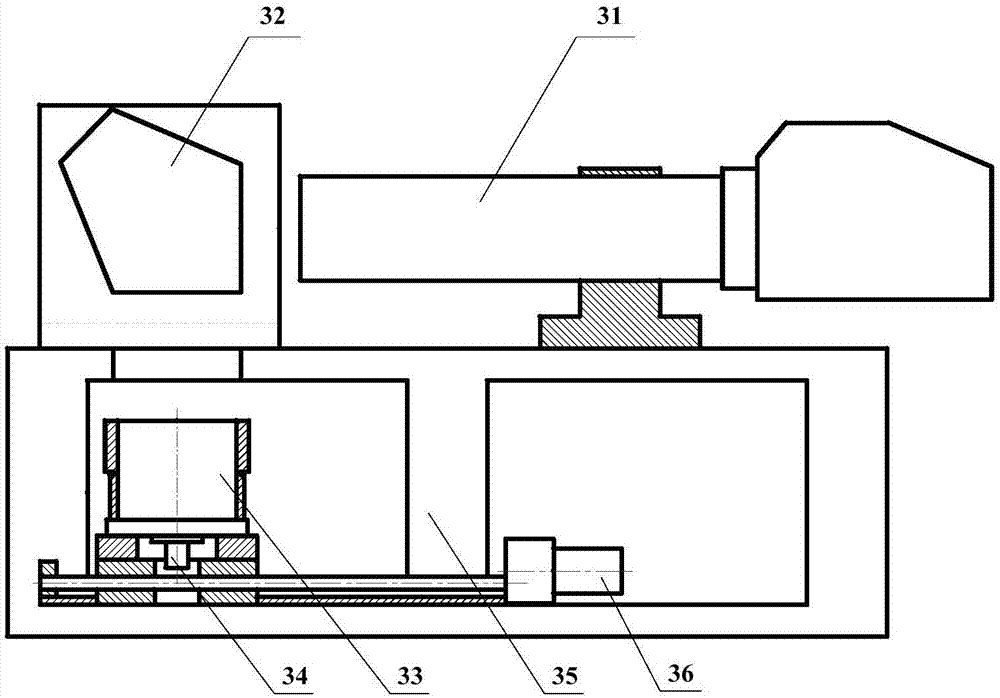

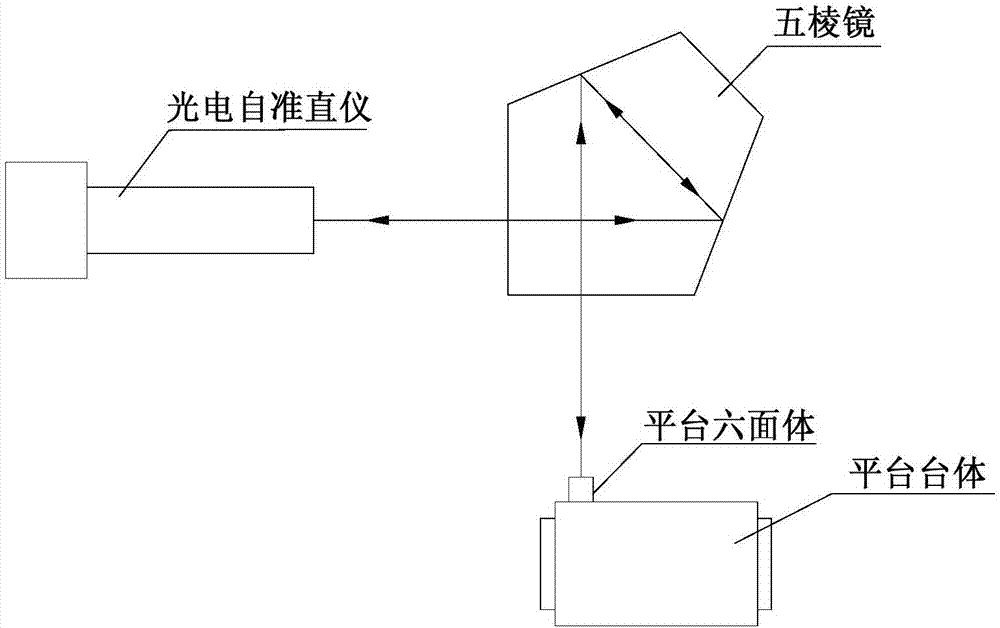

[0050] The leveling and aiming device 3 is assembled with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com