Location fixture for prism roof ridge as well as location and manufacturing methods thereof

A technology for positioning tooling and prism houses, which is applied to metal processing equipment, manufacturing tools, grinding machines, etc., can solve the problem that the angle accuracy is difficult to reach within 30″, achieve simple and fast positioning, ensure grinding stability and precision, and avoid loosening or drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

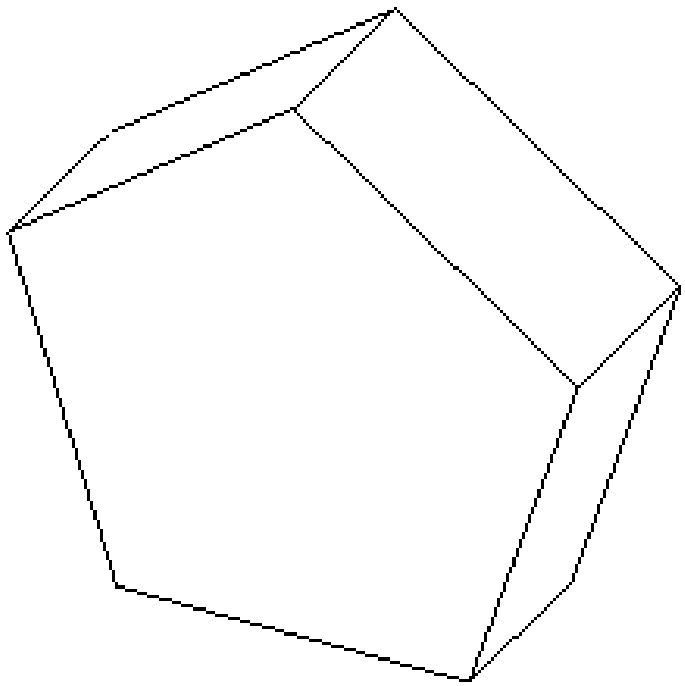

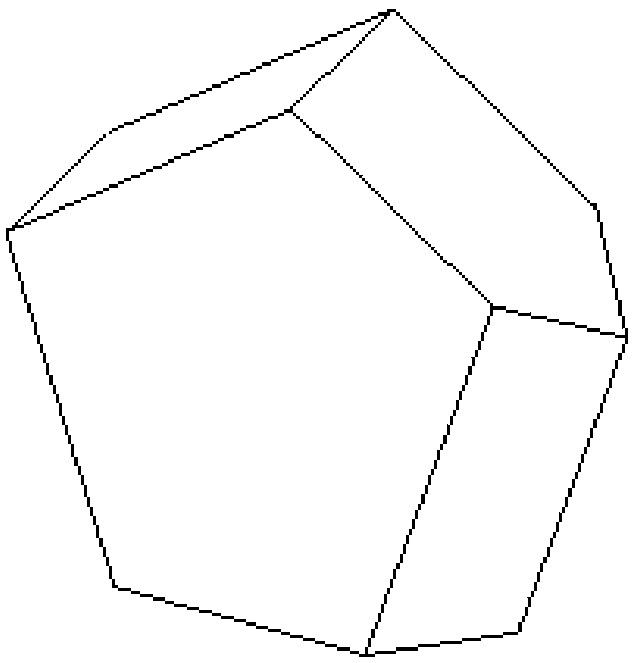

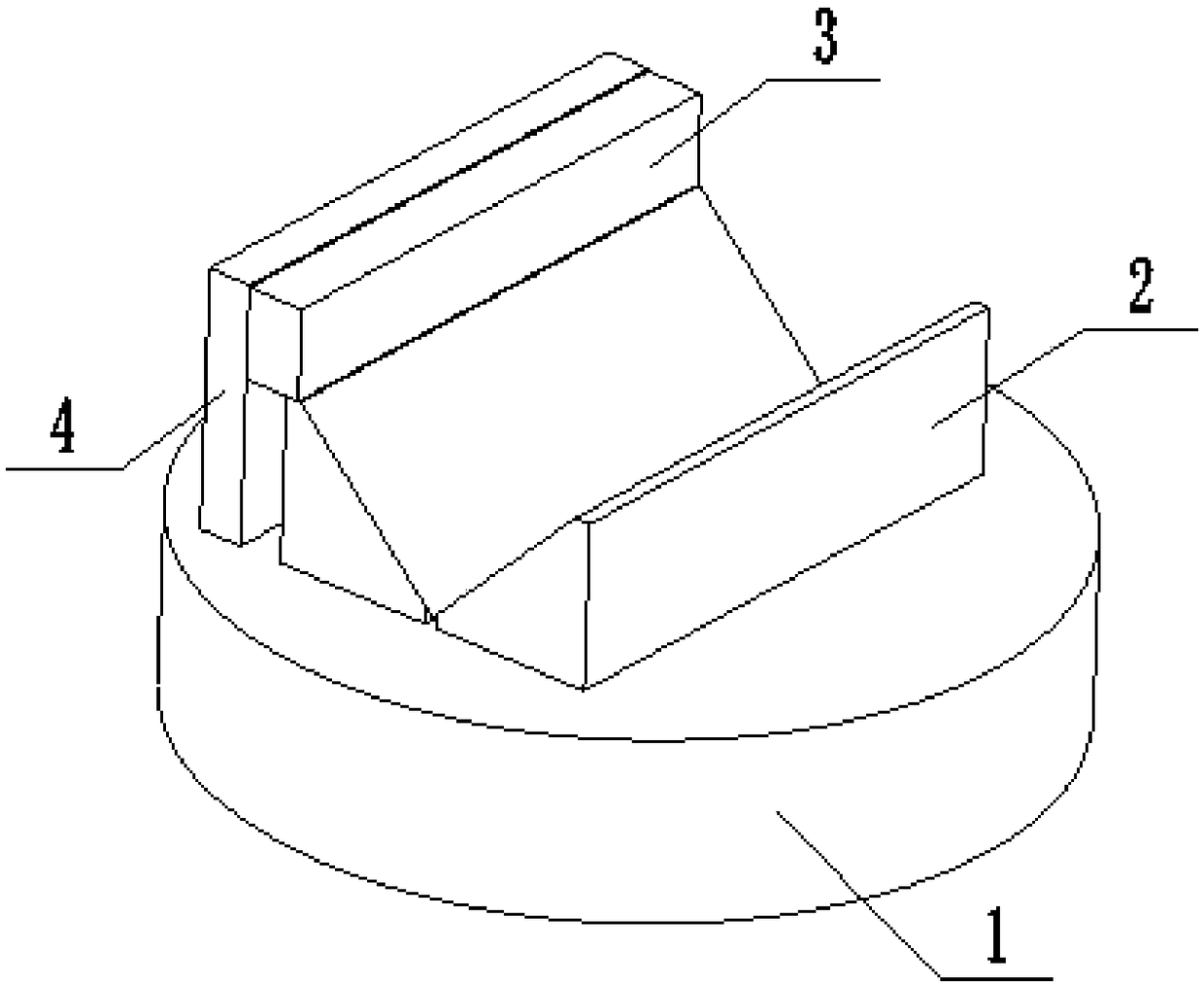

[0055] Such as image 3 As shown, a kind of prism roof edge positioning frock of the present embodiment is specially designed for the processing and positioning of the roof edge of the pentaprism. figure 1 The semi-finished pentaprism shown is ground into figure 2 The cost shown, has two hip faces that meet to form the hip rib. The pentaprism requires that the angle accuracy between the roof ridge and its opposite side is within 30", and the positioning tool is used for positioning to ensure the processing accuracy. The structure of the positioning tool will be described below.

[0056] The positioning tool of this embodiment includes a base plate 1 , a positioning prism 2 , a roof surface positioning block 3 and a supporting block 4 . Wherein, the positioning prism 2 and the supporting block 4 are fixed on the base plate 1, and the roof surface positioning block 3 is fixed on the supporting block 4; the positioning prism 2 is an isosceles right-angled prism, and the roof s...

Embodiment 2

[0066] Present embodiment provides a kind of positioning method of prism roof rib, adopts the positioning tool among the embodiment 1 to carry out positioning before pentaprism processing roof rib, and its operation steps are as follows:

[0067] 1. Preparation of verification documents

[0068] The accuracy of the calibration piece directly determines the assembly accuracy of the positioning tool. The key is to ensure that the vertical accuracy between the detection surface of the reference square prism 6 and the slope of the reference triangular prism 5 is within 5″. For this reason, a second-level optical goniometer is used for calibration The inspection piece is assembled.

[0069] During assembly, a right-angled surface of the reference triangular prism 5 is bonded to the workbench of the goniometer; then, an edge of the reference square prism 6 is in contact with the workbench, and the reference square prism 6 is moved closer to the inclined plane of the reference triang...

Embodiment 3

[0080] This embodiment provides a method for processing the prism roof rib, which is used to figure 1 The semi-finished pentaprism shown is processed into figure 2 As shown in the finished pentaprism, two ridge surfaces are ground and processed, and the ridge is formed at the junction, and the angular accuracy between the ridge and its opposite rectangular side is difficult to reach within 30″. The specific operation steps of this method are:

[0081] 1. Pentaprism blank preparation

[0082] Take a pentaprism blank, satisfying that the parallelism of the two pentagonal faces is within 5", the vertical accuracy between the pentagonal face and the side is within 5", the smoothness of each surface is 80-50, and the aperture is within 1 / 10λ.

[0083] 2. Pentaprism positioning

[0084] The method of Example 2 is used to position the blank of the pentaprism to be processed, and the pentaprism to be processed together with the support body 8 is heated in an oven at a temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com