Reflector adjusting method of laser rotary table

An adjustment method and mirror technology, applied in optics, optical components, installation, etc., can solve problems such as laser interference, inaccurate irradiation position, and low tracking accuracy, and achieve improved tracking accuracy, improved emission pointing accuracy, and high adjustment accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

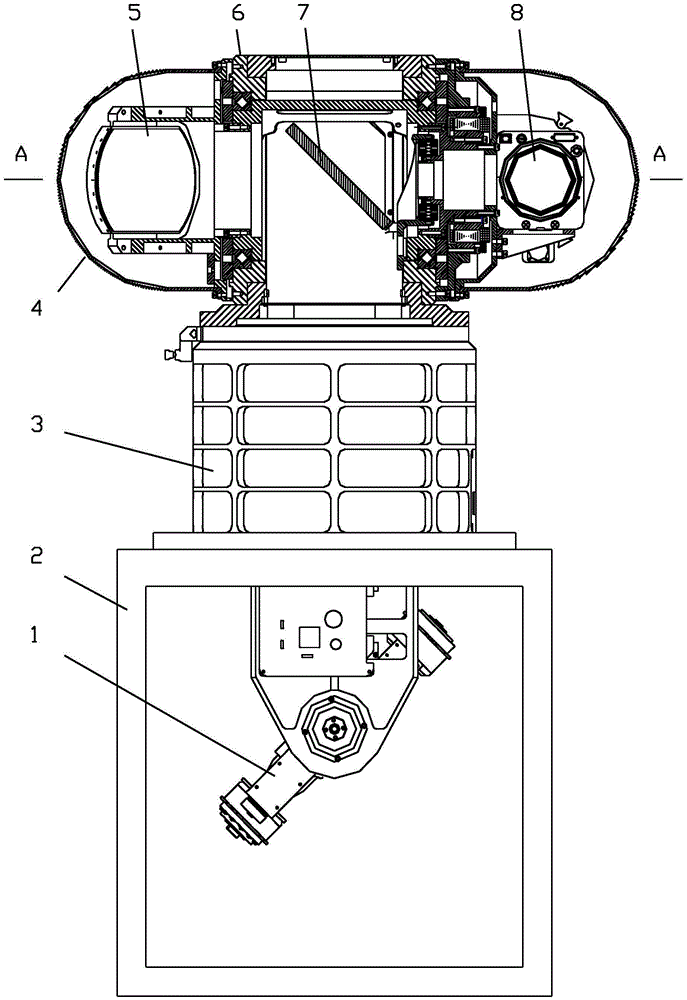

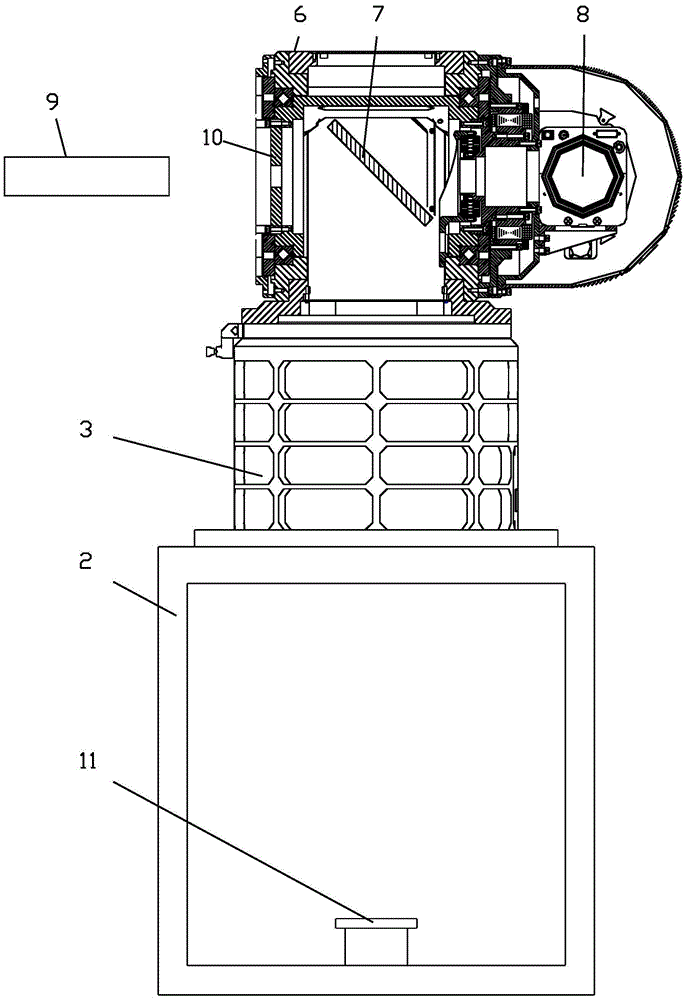

[0015] The present invention comprises the following steps: 1), adjust the third reflector 7: remove the first reflector 1 and the second reflector 5, the first frock reflector 10 is fixed on the left end face of the laser turntable 6, turn the laser turntable For the pitch axis, adjust the first tooling reflector 10 to be perpendicular to the pitch axis, adjust the azimuth seat 3 to be horizontal, place the second tooling reflector 11 under the azimuth seat 3 and adjust the level, use the collimator 9 to observe the reflection through the third reflector 7 Image, adjust the third reflector 7 to make the reflected image coincide with the crosshairs of the collimator 9, remove the first frock reflector 10, and the adjustment of the third reflector 7 is completed, as figure 1 , 2 shown.

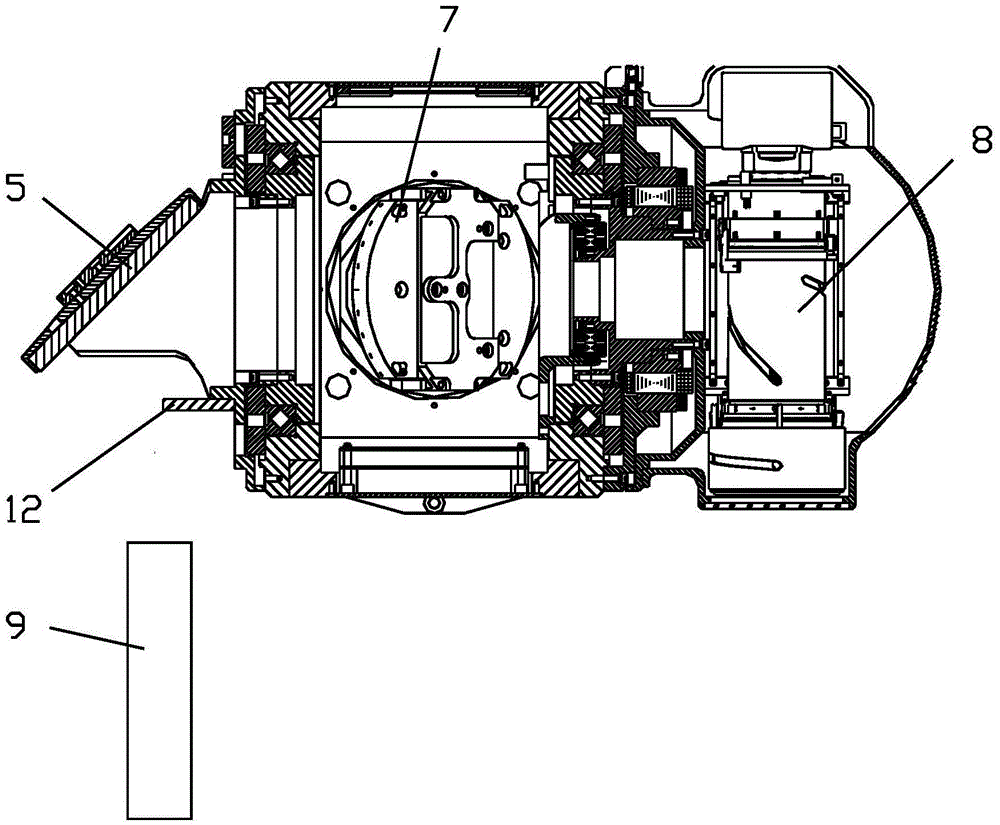

[0016] 2), adjust the second reflector 5: install the second reflector 5 on the left end surface of the laser turntable, stick the third frock reflector 12 on the front end of the fixing frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com