Laser mark automatic tracking extensometer control method based on uncalibrated visual servo

A technology of laser marking and automatic tracking, applied in the direction of adaptive control, control using feedback, general control system, etc., can solve the problems of error, complicated and complicated measurement process, etc., and achieve the effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

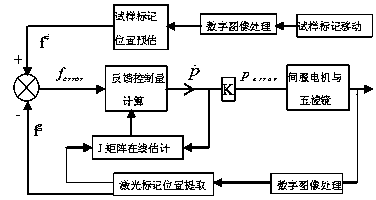

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings and embodiments.

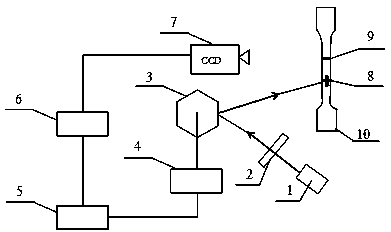

[0030] Material deformation measurement device based on automatic tracking of laser marking, such as figure 2 As shown (see invention patent ZL201110197130.5), the device is also called video extensometer in the present invention, which mainly includes a laser scanning automatic tracking control system (consisting of laser 1, reticle 2, pentaprism 3, servo motor and Drive 4), computer 5, image acquisition card 6, CCD7, laser marking 8, sample marking 9 and sample 10 and other parts. When the system is working, the CCD is fixed in front of the mark of the sample to be tested, and records the movement trajectory of the laser mark and the sample mark in the same plane. The servo motor drives the pentaprism to rotate, so that the laser mark tracks the sample mark and completes the measurement of material deformation.

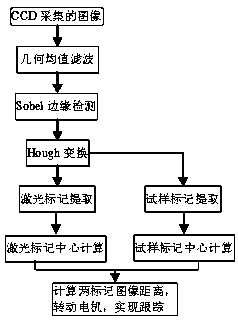

[0031] A digital image processing meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com