Detection system for long-range optical surface profile

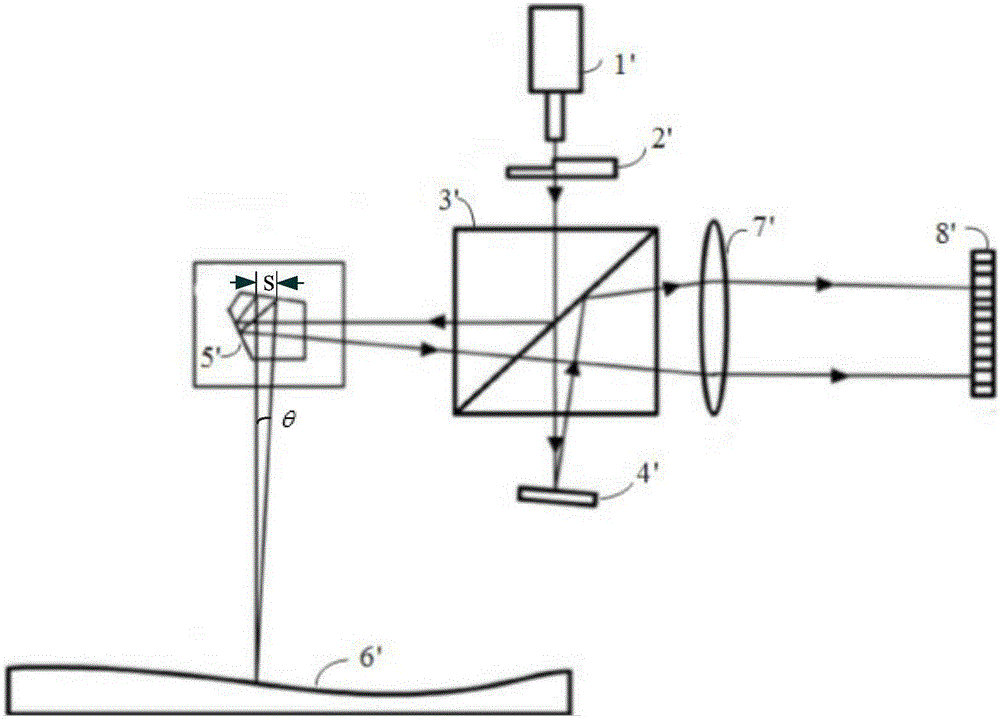

A detection system and surface technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve problems such as errors, and achieve the effects of compact structure, small spacing, reduction of number, and reduction of system errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

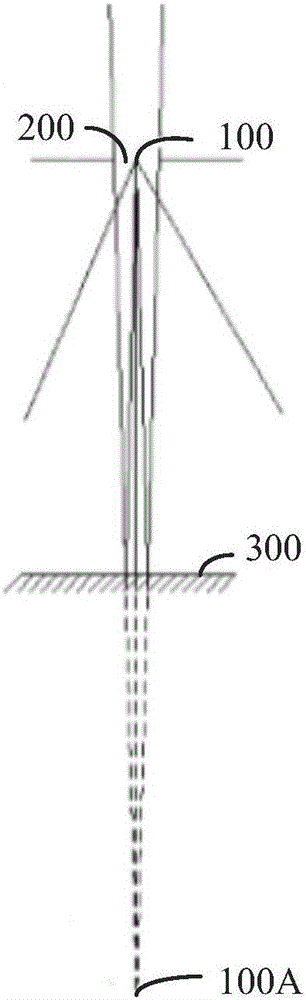

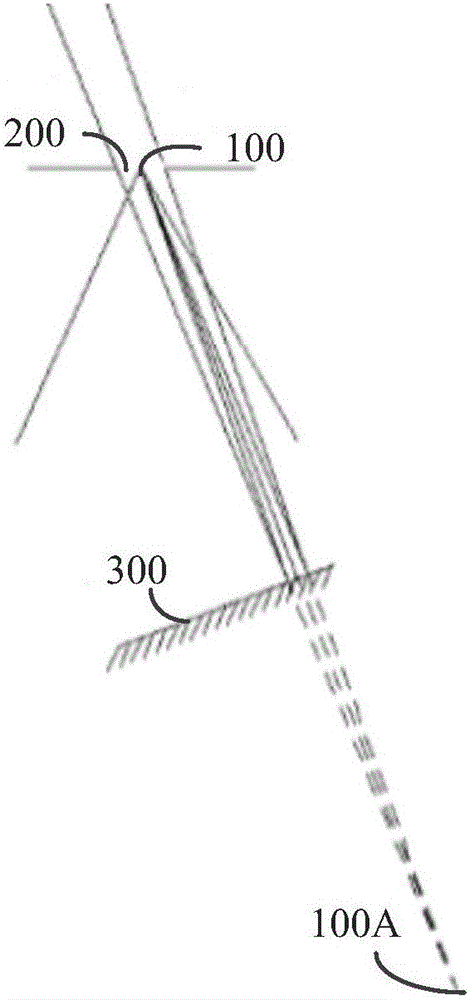

[0029] It is known in the art that, as Figure 2a As shown, if the point light source 100 is placed at the center of the hole 200, the light beam emitted by the point light source 100 can be regarded as the light beam emitted by the image 100A formed by the plane mirror 300 on the light source 100 after being reflected by the plane mirror 300. According to the principle of mirror reflection, the light beam passing through the center of the hole 200 after mirror reflection must propagate along the normal direction of the plane mirror 300, so the light beam passing through the hole 200 after mirror reflection is a cone that propagates along the normal direction of the mirror surface and has a small divergence angle. Shaped light beam, the size of its divergence angle is determined by the diameter of the hole 200 and the distance between the hole 200 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com