Impacting tester with double pendulum and testing method thereof

A technology of impact testing machine and test method, which is applied in the direction of testing the strength of materials with one-time impact force, can solve the problems of lack of impact test methods and equipment for thin plates and their connecting joints, and achieve simple and easy test methods and accurate test results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

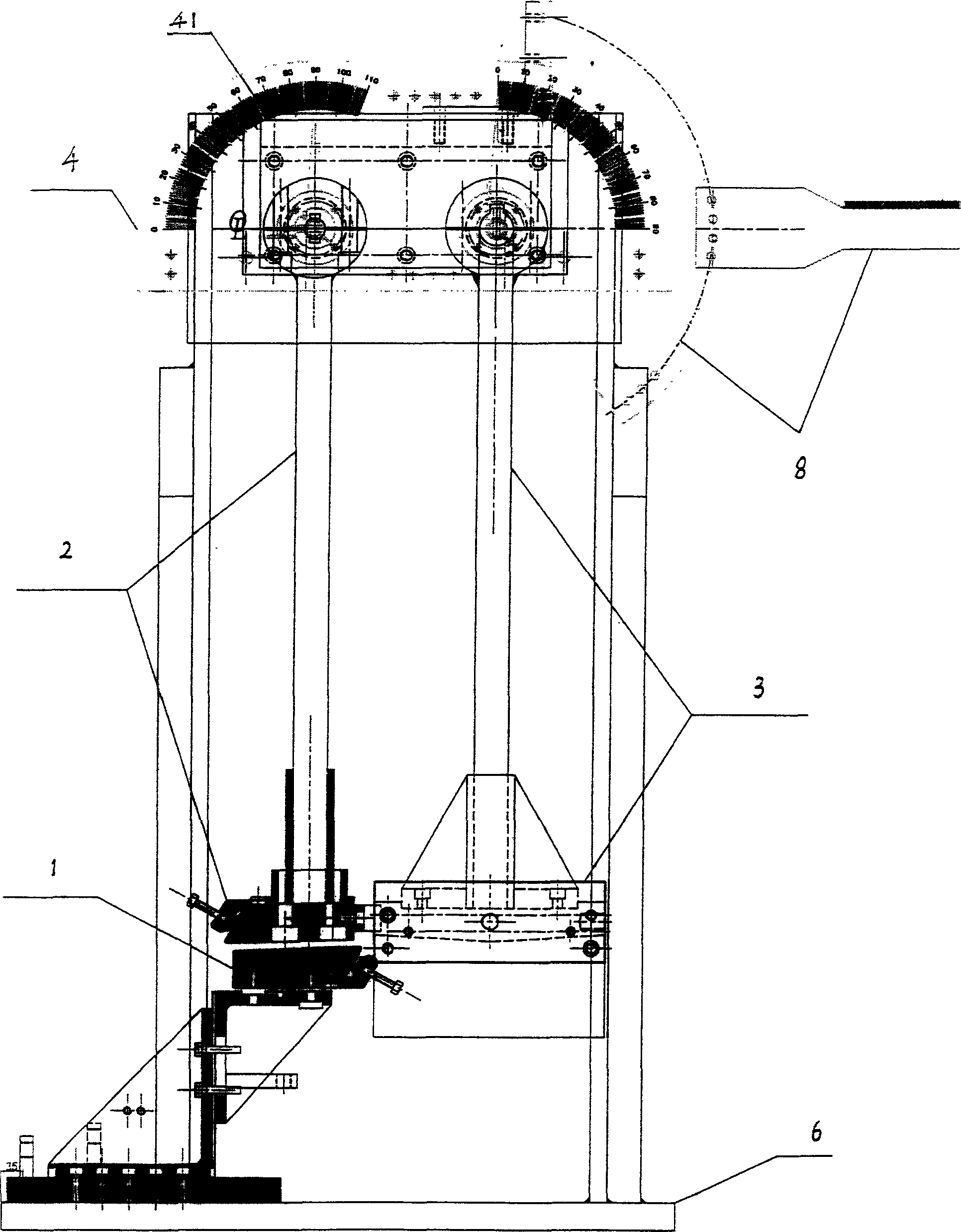

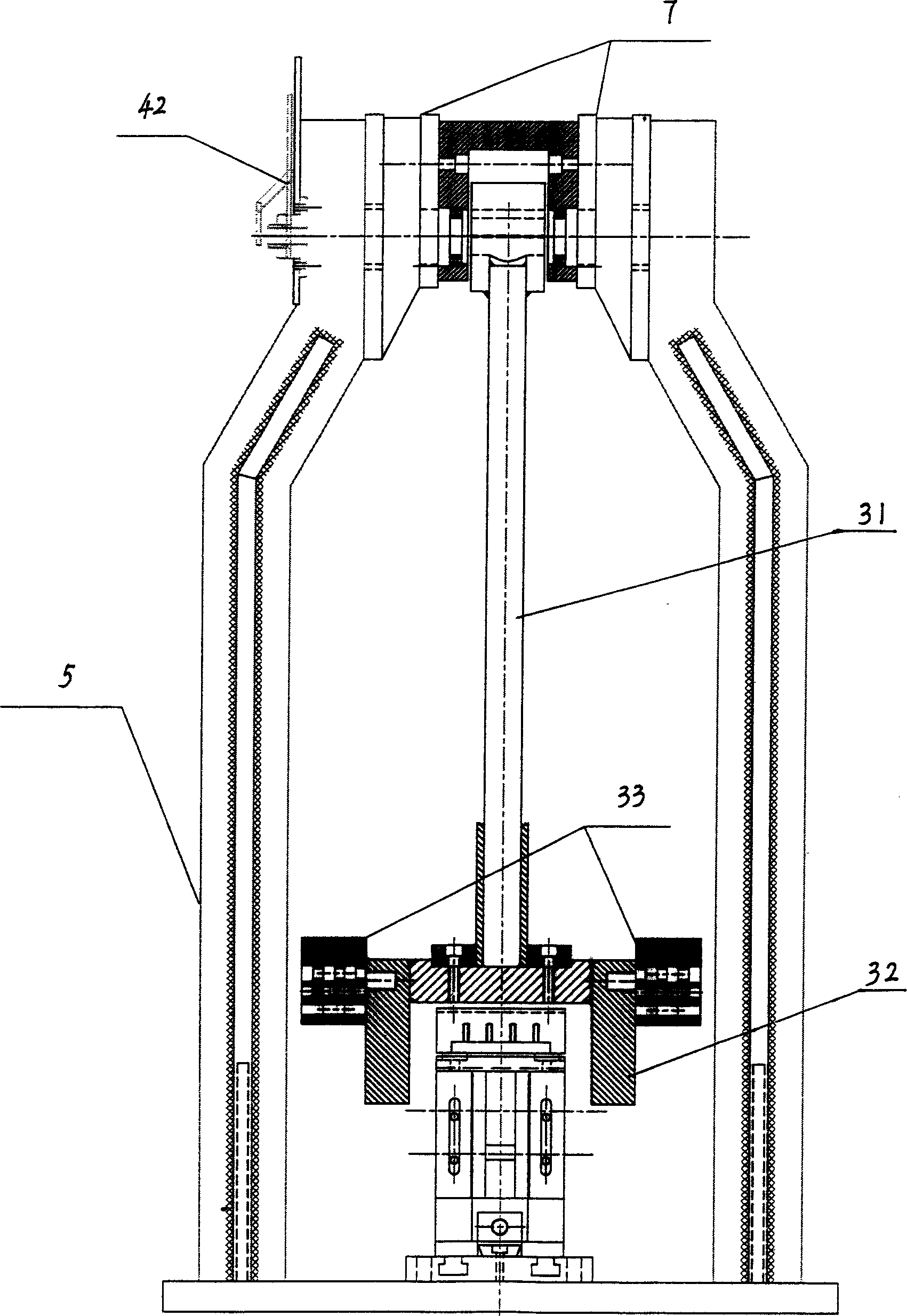

[0035] Such as Figure 1~8 As shown, the present invention is composed of a frame, a sample base 1, a driven pendulum 2, an active pendulum 3, a dial 4, and a braking system.

[0036] 1. It has a frame composed of 4 or more uprights 5, bottom plate 6, axle frame 7, active pendulum lifting angle setting and release mechanism 8, see attached figure 1 ;

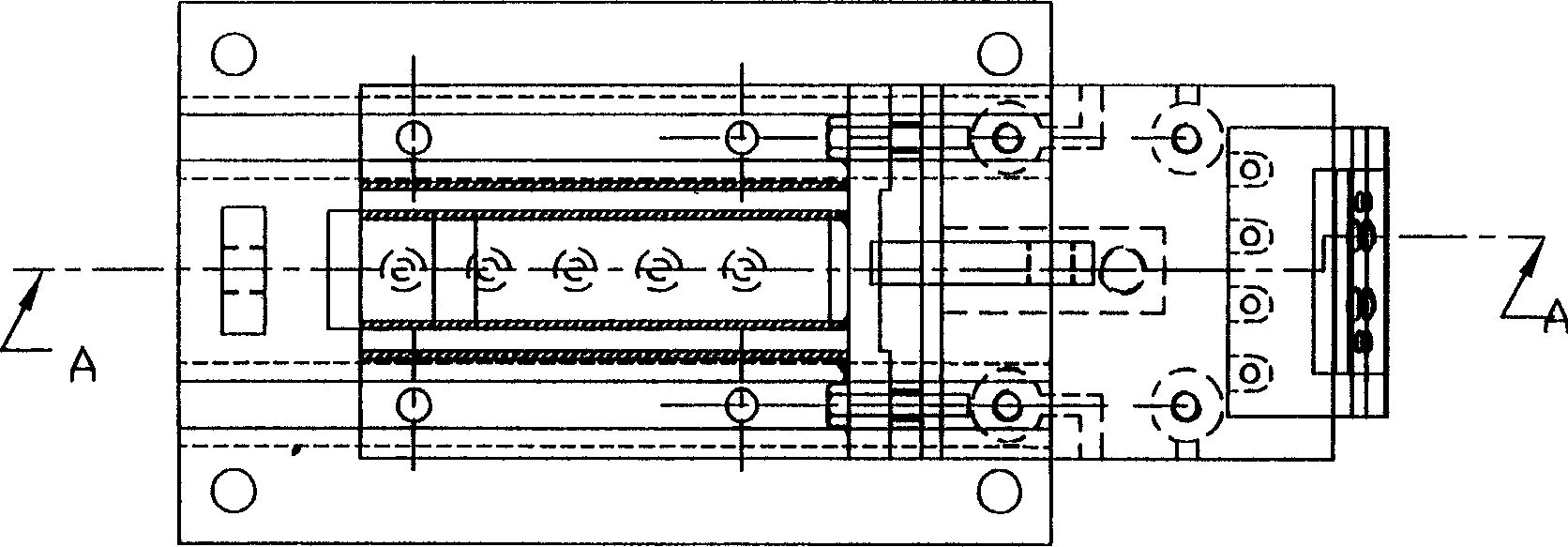

[0037] 2. There is a sample base 1 with a pressing device 11 on the side, the pressing device 11 serves to fix one side of the impact sample; the upper surface of the sample base 1 (the side adjacent to the driven pendulum) has The inclination angle of 0-90° (5° in this embodiment) ensures that no friction or even squeezing occurs with the pendulum and the sample that continue to punch after the sample is punched, see attached figure 1 with figure 2 ;

[0038] 3. It has a driven pendulum composed of a first connecting rod 21 and a pendulum 23 with a pressing device 22 on the side. The pressing device serves to fix the other side o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com