Simulation test device for thrust force of large-thrust-force double-pendulum engine

A technology of double pendulum engine and simulation test, which is applied in the direction of engine test, measuring device, machine/structural component test, etc., to achieve the effect of simple structure, convenient adjustment, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

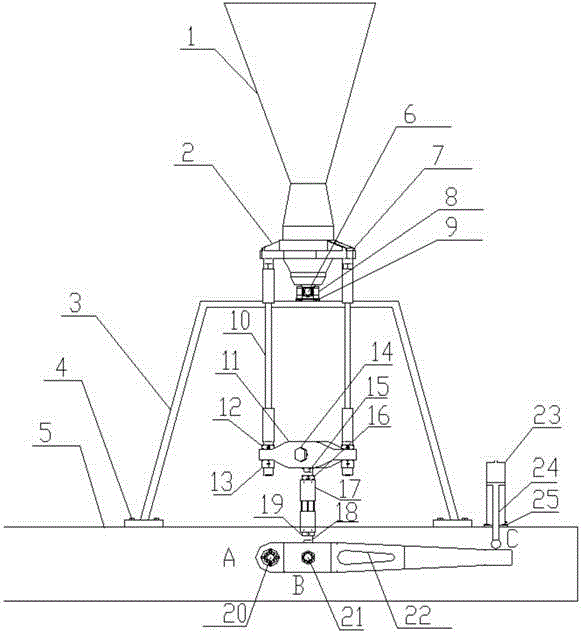

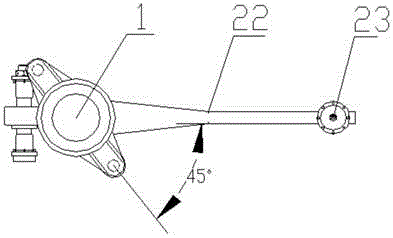

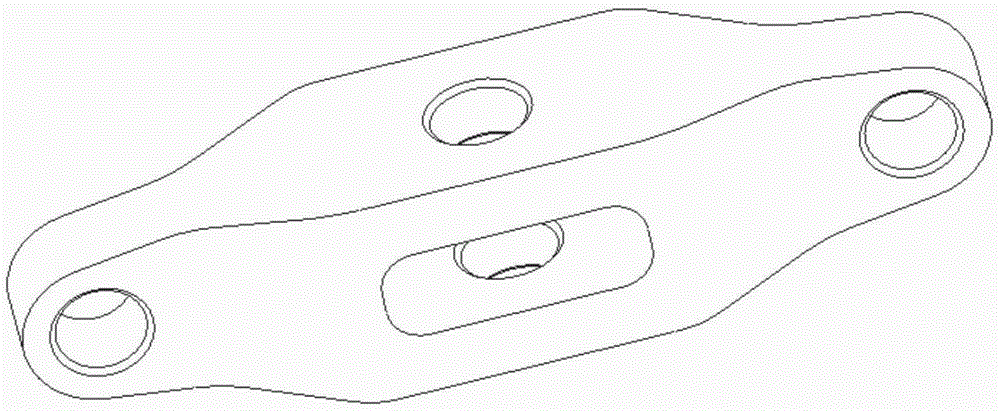

[0024] Such as figure 1 As shown, a high-thrust double pendulum engine thrust simulation test device, the device includes two bearing lugs 2, engine frame 3, bolts 4, base 5, swing cross shaft 6, backup nut 7, gimbal 8. Bolt 9, two wire ropes 10, connecting block 11, back-up nut 12, back-up nut 13, first pin shaft 14, first joint bolt 15, back-up nut 16, adjustment pull rod 17, second joint bolt 18 , back-up nut 19, the second bearing pin 20, the 3rd bearing pin 21, lever 22 and loading hydraulic cylinder 23; The two ends of steel wire rope 10 have thread;

[0025] The engine 1 is connected to the gimbal 8 through the swing cross shaft 6, the gimbal 8 is fixedly connected to the engine frame 3, and the engine frame 3 is fixedly connected to the base 5;

[0026] Two load-bearing lugs 2 are fixedly connected to both sides of the main load-bearing part of the engine 1, and the upper ends of the two steel wire ropes 10 are respectively threaded with one load-bearing lug 2;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com