Double-sided double-pendulum blind-zone-free welding tractor and welding method thereof

A technology of welding trolley and no blind area, which is applied in the direction of welding/welding/cutting items, welding equipment, auxiliary welding equipment, etc., which can solve the problems of affecting welding quality, inability to weld completely, and large blind area of one-time welding, etc. The burden of technicians, the effect of easy double-sided symmetrical welding, and easy double-sided staggered welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

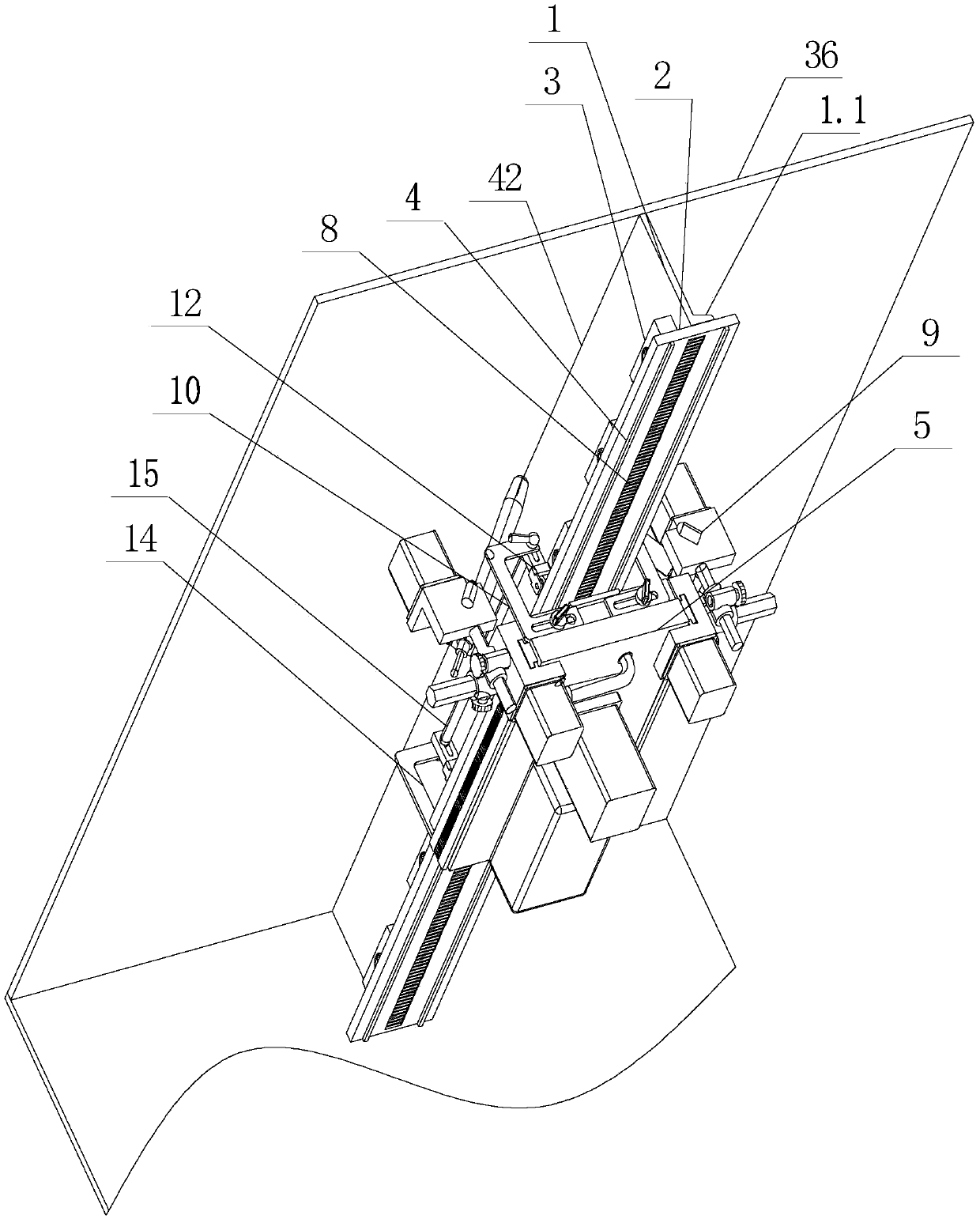

[0023] After the superstructure of the hull is closed up, the flat bulb steel 1 and the vertical hull steel plate 36 are T-shaped vertical fillet welds, and the T-shaped vertical fillet welds are shown in 42 labels.

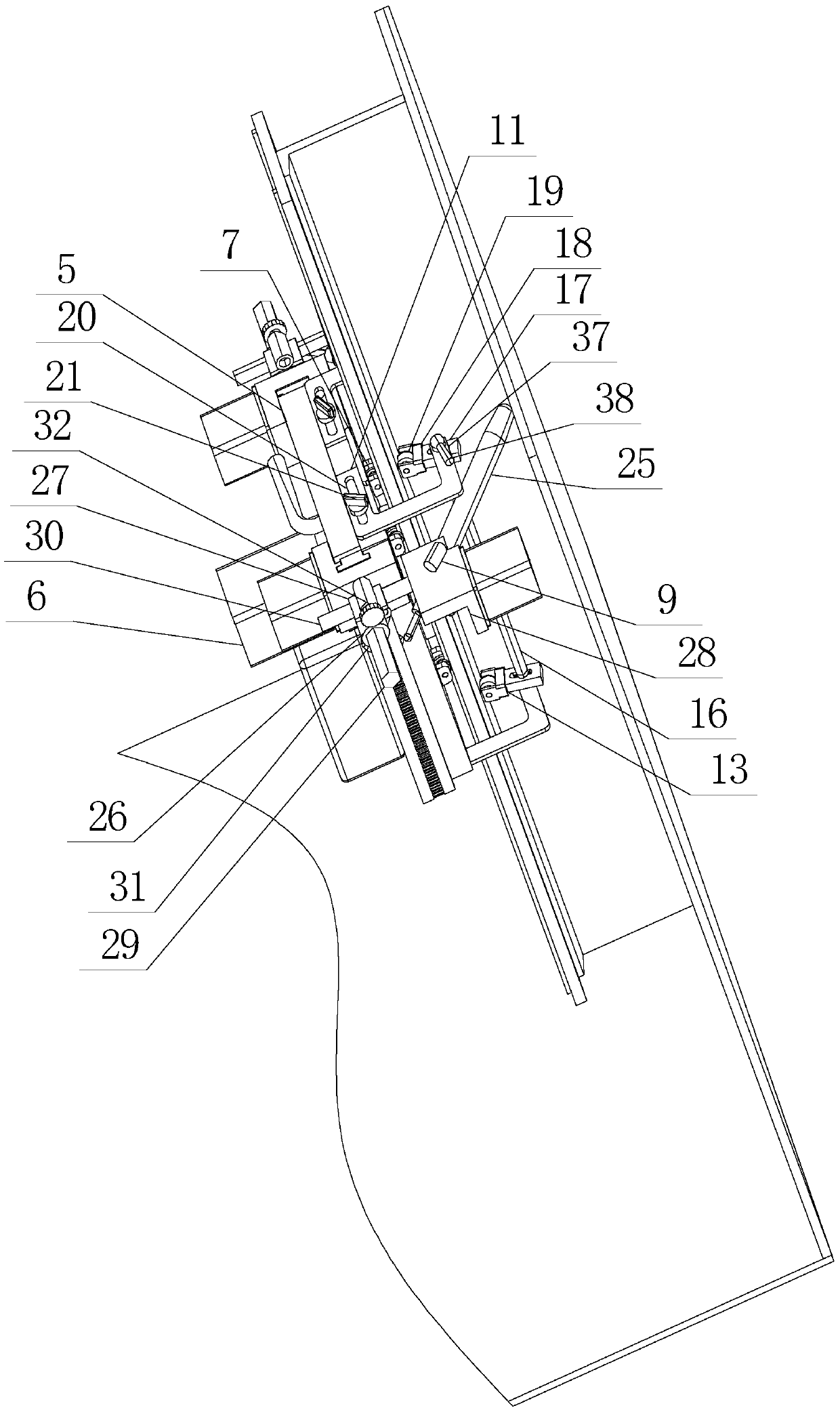

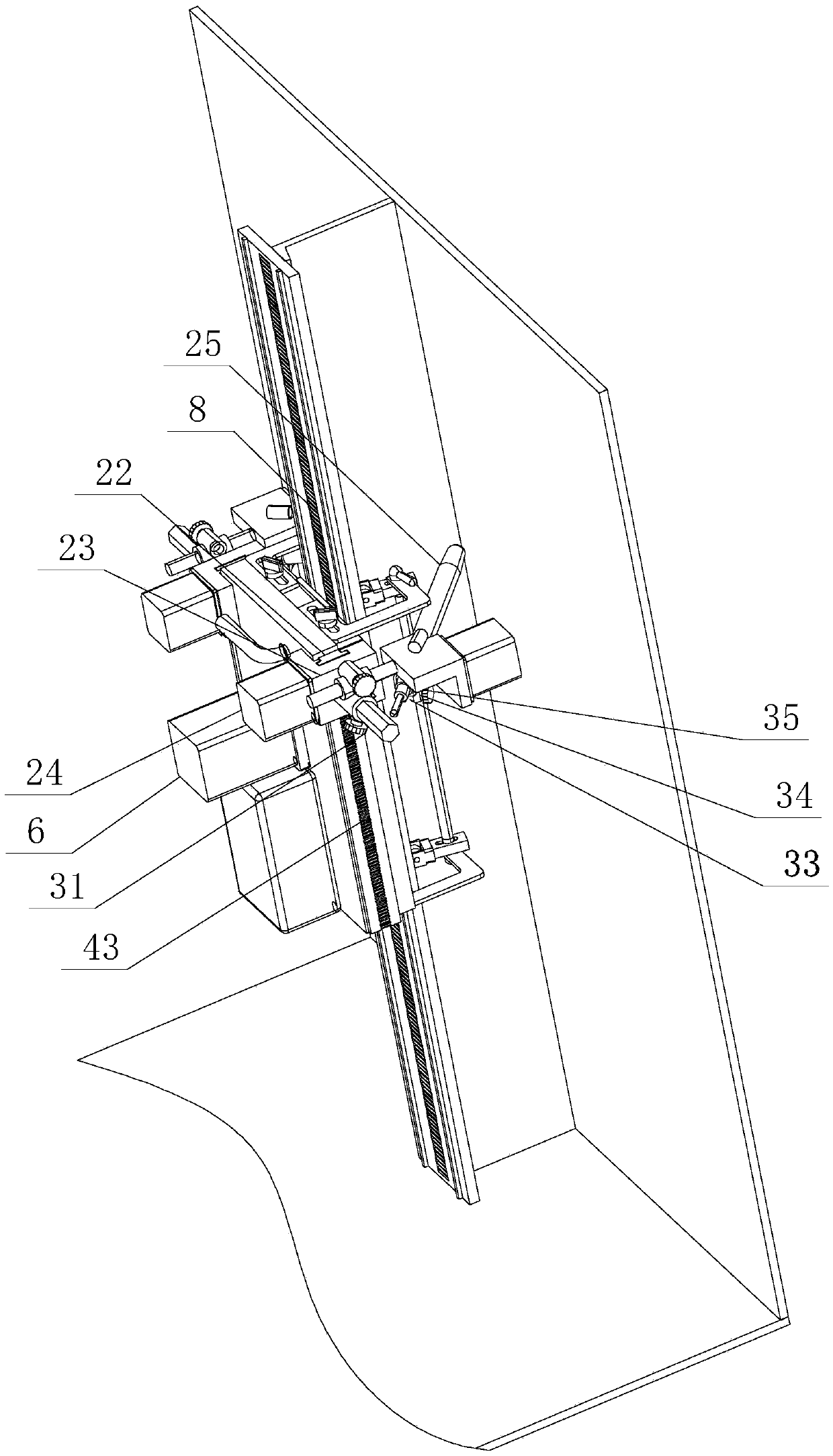

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, a double-sided double-pendulum welding trolley without blind spots of the present invention includes a rail climbing device, a welding device, a monitoring device for monitoring and real-time adjustment of welding parameters, and a linear track arranged on the flat bulb steel 1; The linear track includes a square flat plate 2 closely attached to the outer end surface of the ball head 1.1 of the spherical flat steel 1 and a plurality of magnetic adsorption blocks 3 closely attached to the side surface of the spherical flat steel 1. The blocks 3 are all arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com