Method for detecting linkage accuracy of C-shaft of multi-shaft linkage double-pendulum numerical control milling machine

A CNC milling machine and multi-axis linkage technology, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of repeated inspection times, unable to objectively reflect the accuracy of C-axis linkage, and low degree of automation. Achieve direct and effective detection results, fast and effective analysis, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

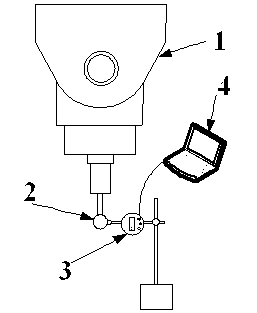

[0015] figure 1 It is a detection method of the C-axis linkage accuracy of a multi-axis linkage double-oscillating head CNC milling machine of the present invention, including the following steps: installing the standard ball head 2 on the main shaft of the machine tool, and setting the working length L of the standard ball head 2 in the machine tool system and the diameter of the ball head D; a digital display dial gauge 3 with data acquisition and output is set up on the machine bed, and the probe of the digital display dial gauge 3 is pressed into a certain distance d after contacting the standard ball head 2, and the current data Reset the position of the display dial indicator 3 to zero; turn on the RTCP movement mode of the machine tool to make the C-axis 1 rotate around the center of the standard ball head 2; Displacement deviation △l, the value of displacement deviation △l at different rotation angles is the linkage accuracy of C-axis 1 of the multi-axis linkage double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com