Accessory type double pendulum angle milling head driven by alternating-current permanent-magnet synchronous inner rotor torque motor

A technology of double pendulum angle milling head and torque motor, which is applied to machine tool parts, metal processing machinery parts, milling machine equipment, etc., can solve problems such as poor rigidity and complex structure, and achieve good linear characteristics, compact overall structure, and machining range Extended effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

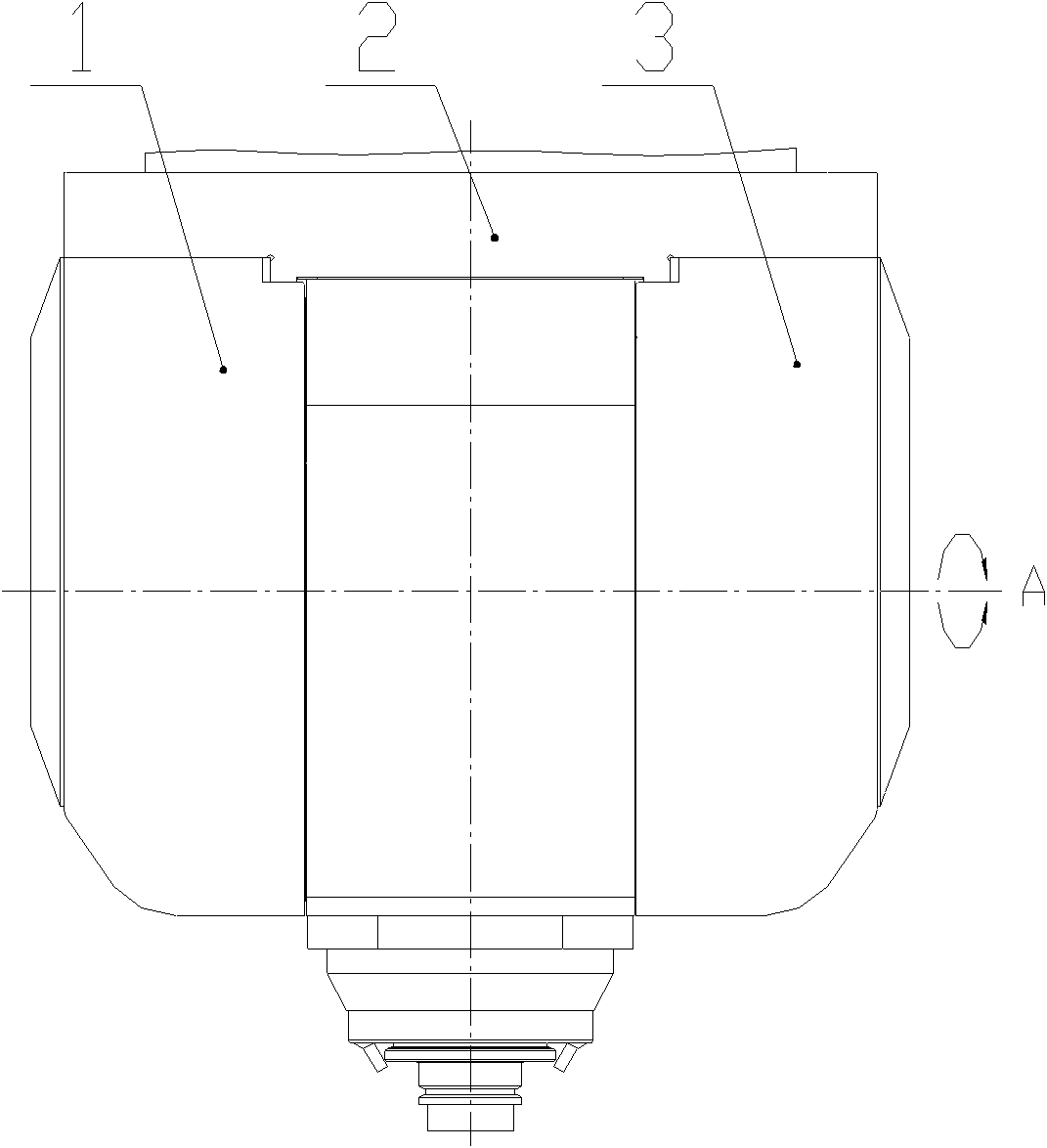

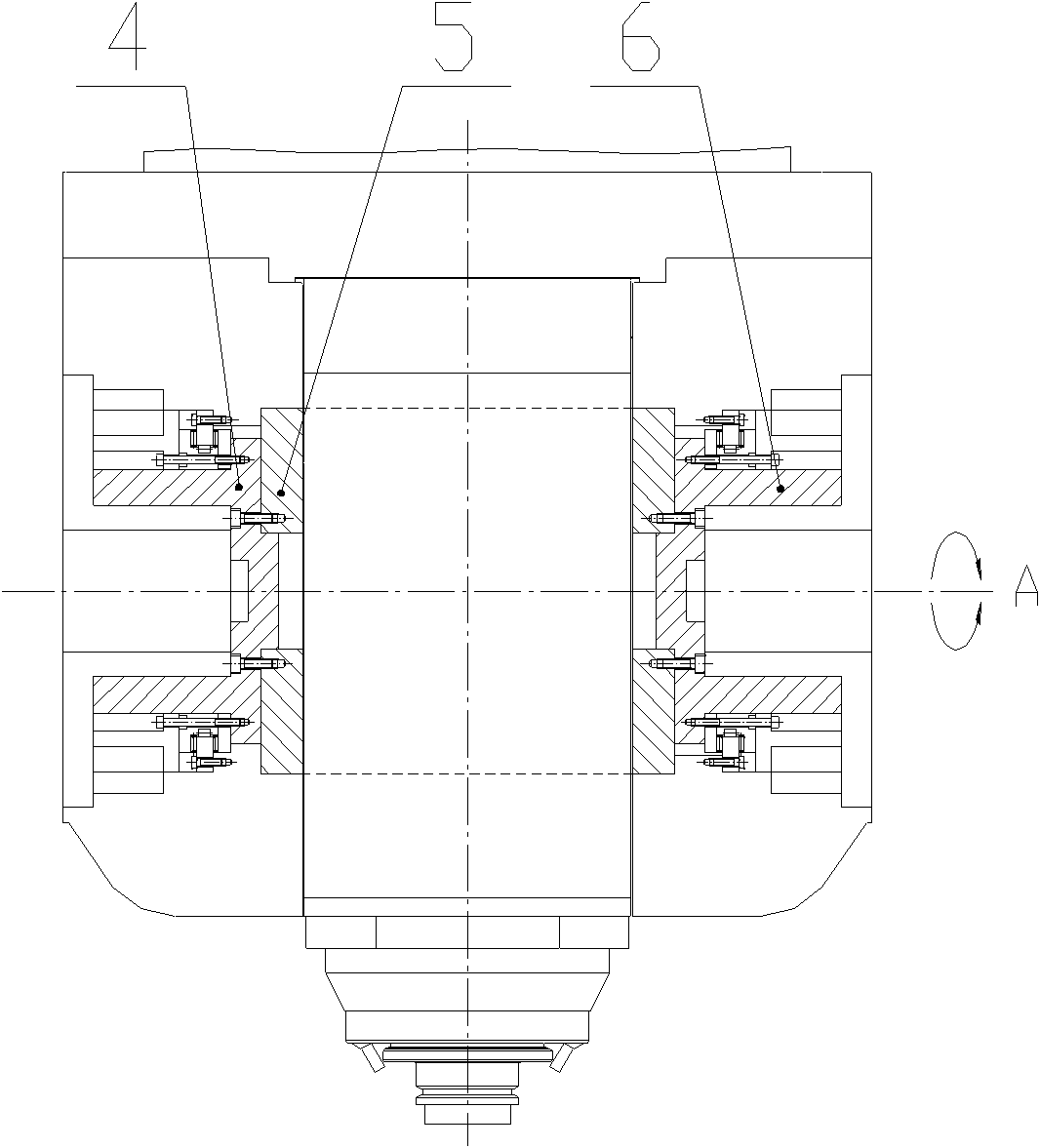

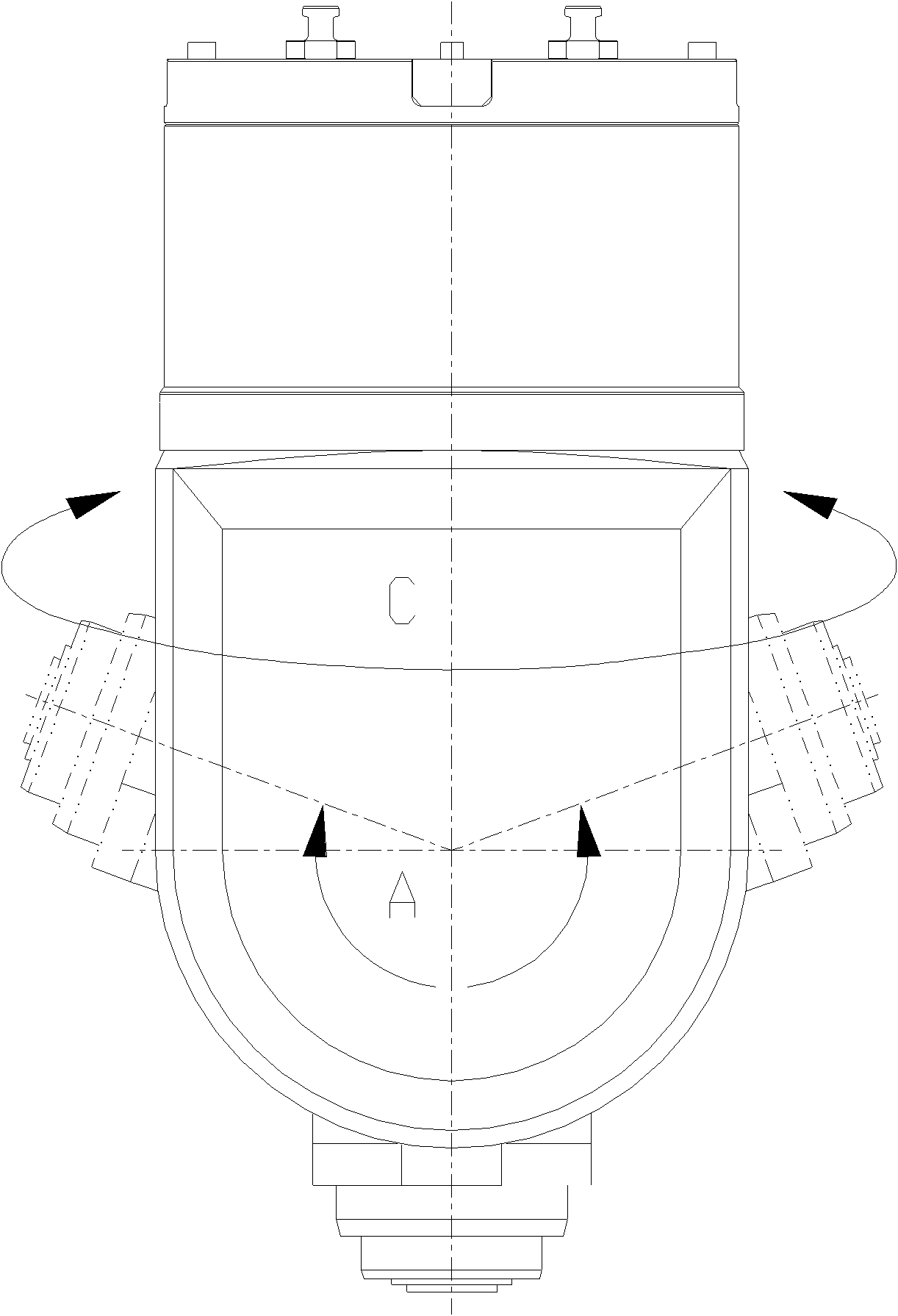

[0016] Depend on Figure 4 combine image 3 , 5 , shown in 6 and 7, a kind of accessory type double pendulum angle milling head driven by AC permanent magnet synchronous inner rotor torque motor, comprises fork frame 22, main shaft 24, rotary joint assembly 20, described fork frame 22 and The main shaft 24 is all one-piece, and its structure will be described in detail below. This one-piece structure is different from the previous split structure, which makes the main shaft more rigid and makes the overall structure more compact. The top of the fork frame 22 has a motor base 10, the top of the motor base 10 is fixed with a connecting plate 8, the upper part of the connecting plate 8 is fixed with a pull stud 7, and the side is provided with a positioning key 19. By increasing the connecting plate 8, the The pull stud 7 and the positioning key 19 can be used to be connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com