Polishing device with two swing shafts for high-gradient aspheric optical parts

A technology for optical parts and polishing devices, applied in the field of optical parts processing, can solve the problems of uneven force, pressure instability, unstable removal function, etc., and achieve the effects of high efficiency, easier realization of precision, and stable removal performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

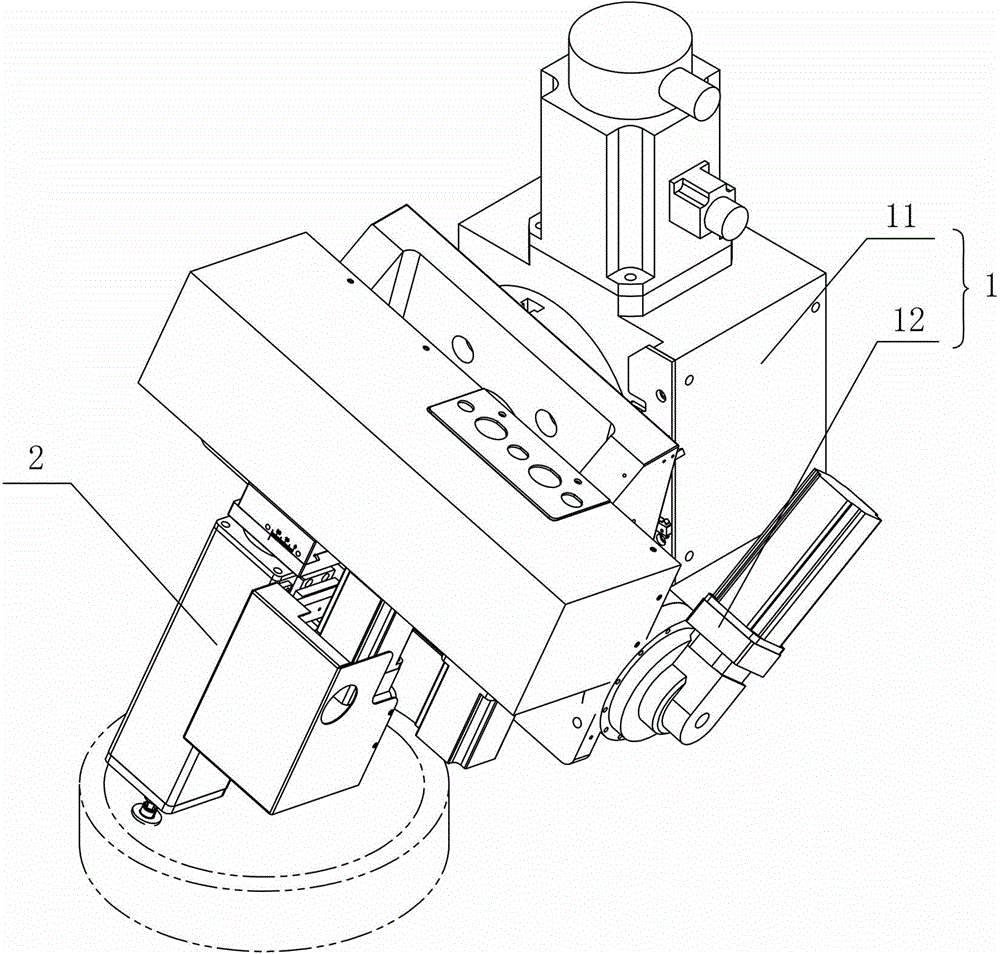

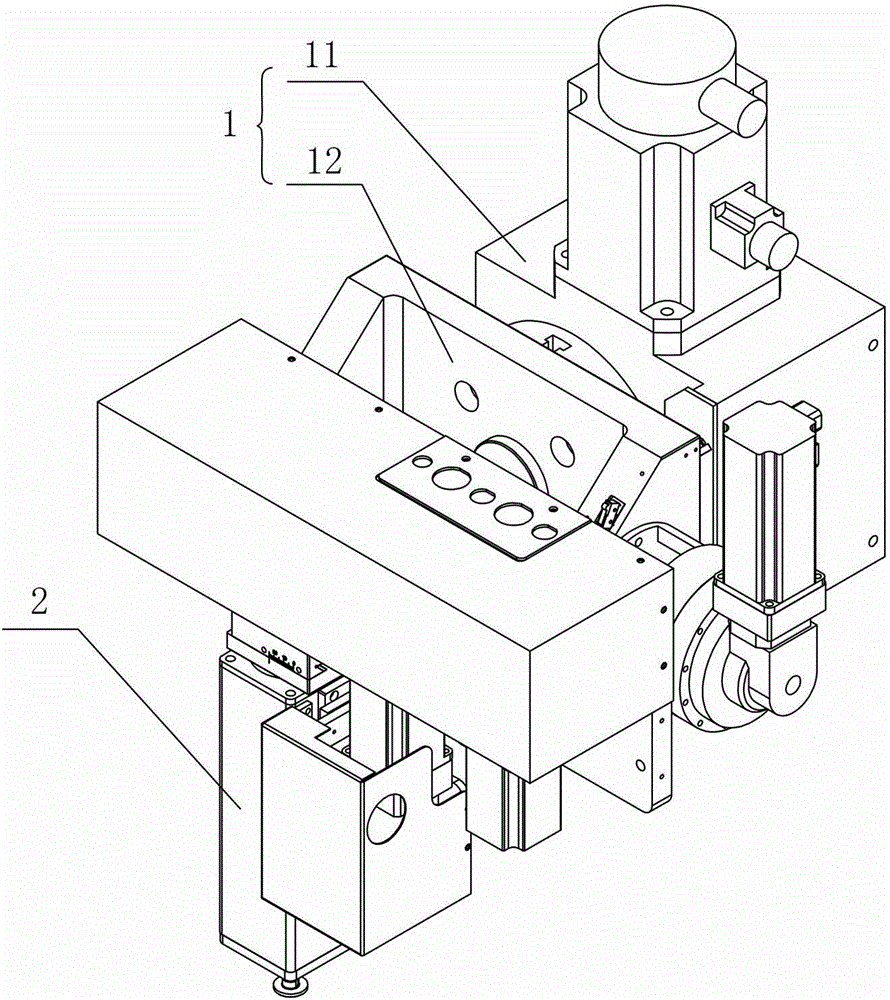

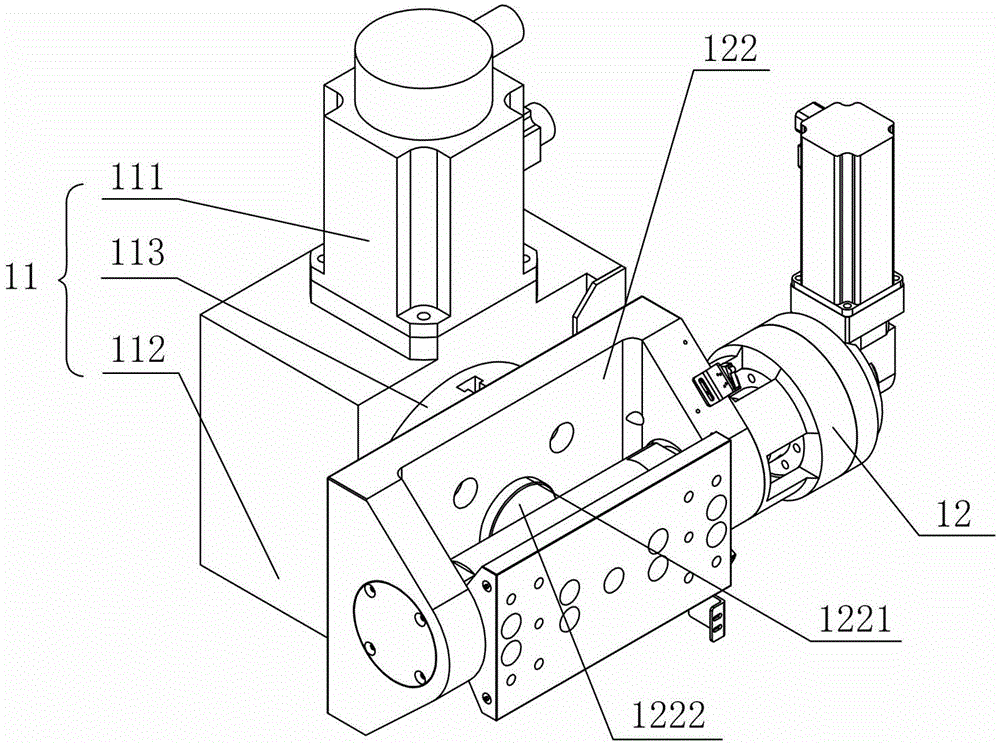

[0029] Figure 1 to Figure 7 Shows an embodiment of the dual pendulum shaft polishing device for high steep aspheric optical parts of the present invention, including a dual pendulum shaft mechanism 1 and a dual rotor polishing mechanism 2, the dual pendulum shaft mechanism 1 includes a deflection assembly 11 and The pitch assembly 12 is installed at the yaw movement output end of the yaw assembly 11, the dual-rotor polishing mechanism 2 is installed at the pitch movement output end of the pitch assembly 12, the yaw axis rotation line of the yaw assembly 11 and the pitch The pitch rotation axis of the assembly 12 is orthogonal. The yaw assembly 11 and the pitch assembly 12 provide a two-dimensional rotation function, and the dual-rotor polishing mechanism 2 generates a Gaussian removal function. The two-dimensional rotation adjustment of the yaw assembly 11 and the pitch assembly 12 can make the axis of the dual-rotor polishing mechanism 2 always Coinciding with the normal dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com