Converter dry method dust-removing explosion-venting control method

A converter dry dust removal and control method technology, applied in the manufacture of converters, etc., can solve the problems of low automation and incomplete measures, reduce the number of explosion vents, avoid human interference, and solve the effect of high explosion venting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

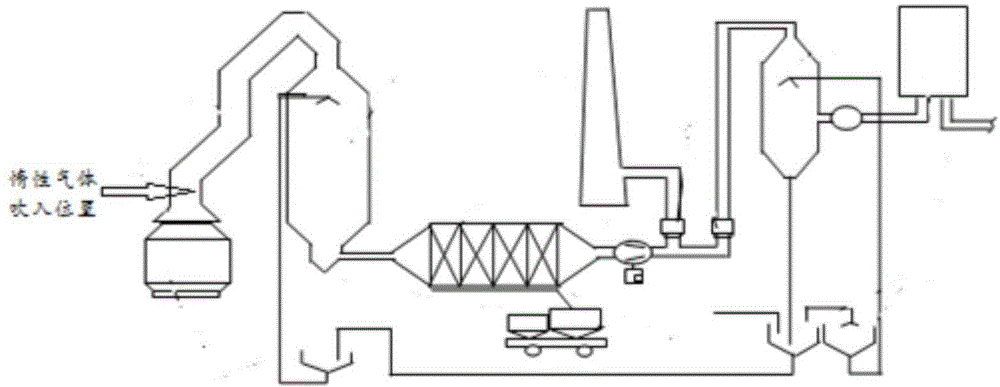

[0027] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

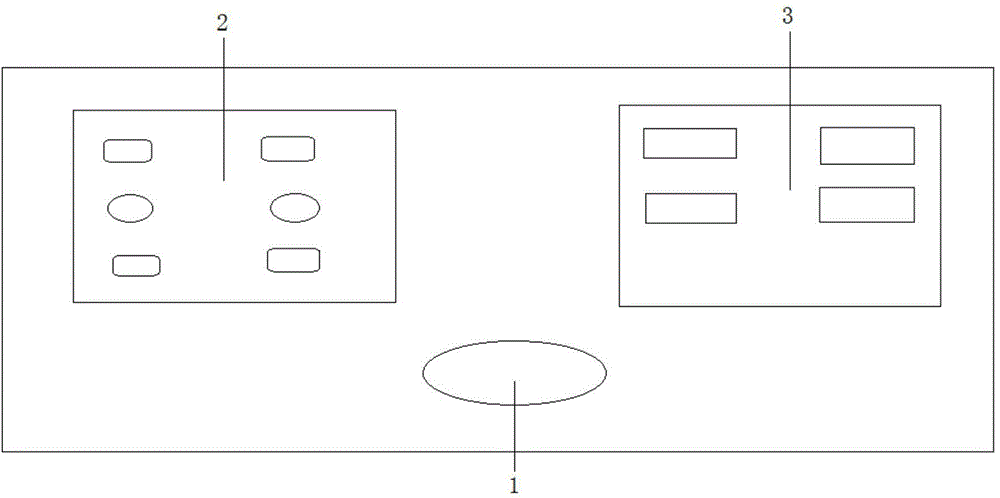

[0028] In this embodiment, a control method for dry dust removal and explosion relief of a converter is provided. The control method for dry dust removal and explosion relief of a converter includes an automatic control method for explosion relief and an auxiliary operation method. The automatic control method for explosion relief is set in the automatic control system of the converter The explosion venting automatic control system is controlled by fan speed control, converter smoke hood lifting control, inert gas blowing setting, oxygen lance flow program setting, feeding frequency and feeding amount control during the converter blowing process and converter blowing process. , Electrostatic precipitator double pendulum valve setting, electrostatic precipitator oxygen content monitoring, implementation of explosion venting control measures during converter blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com