AC permanent magnet disc type torque motor drived large-torque double-pendulum milling head

A technology of torque motor and high torque, applied in the field of combined mechanism of five-coordinate linkage processing, can solve the problems of increasing the winding space of the motor winding, increasing the volume of the iron core, etc., and achieves high motor efficiency, high magnetic field utilization, and good heat dissipation conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

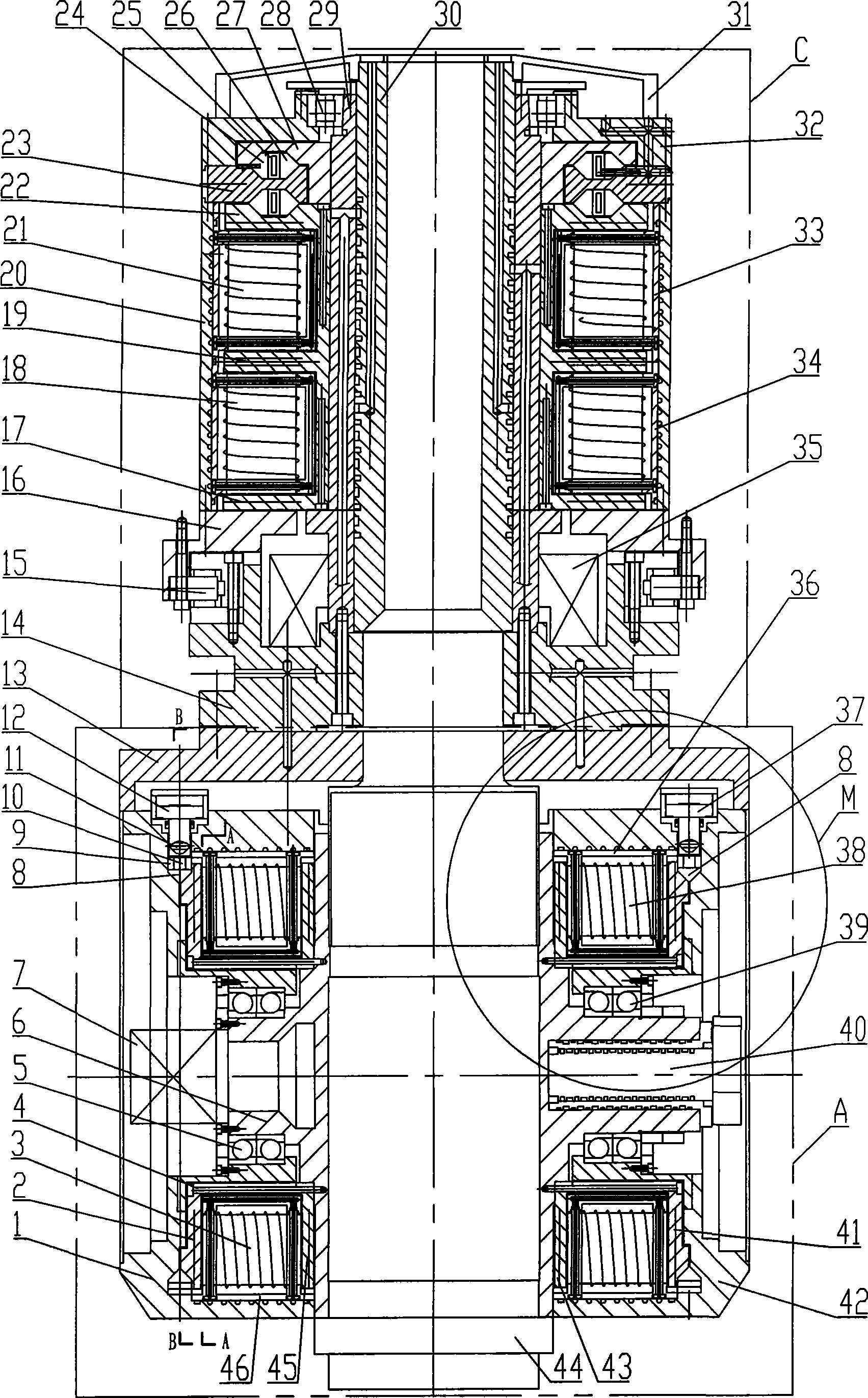

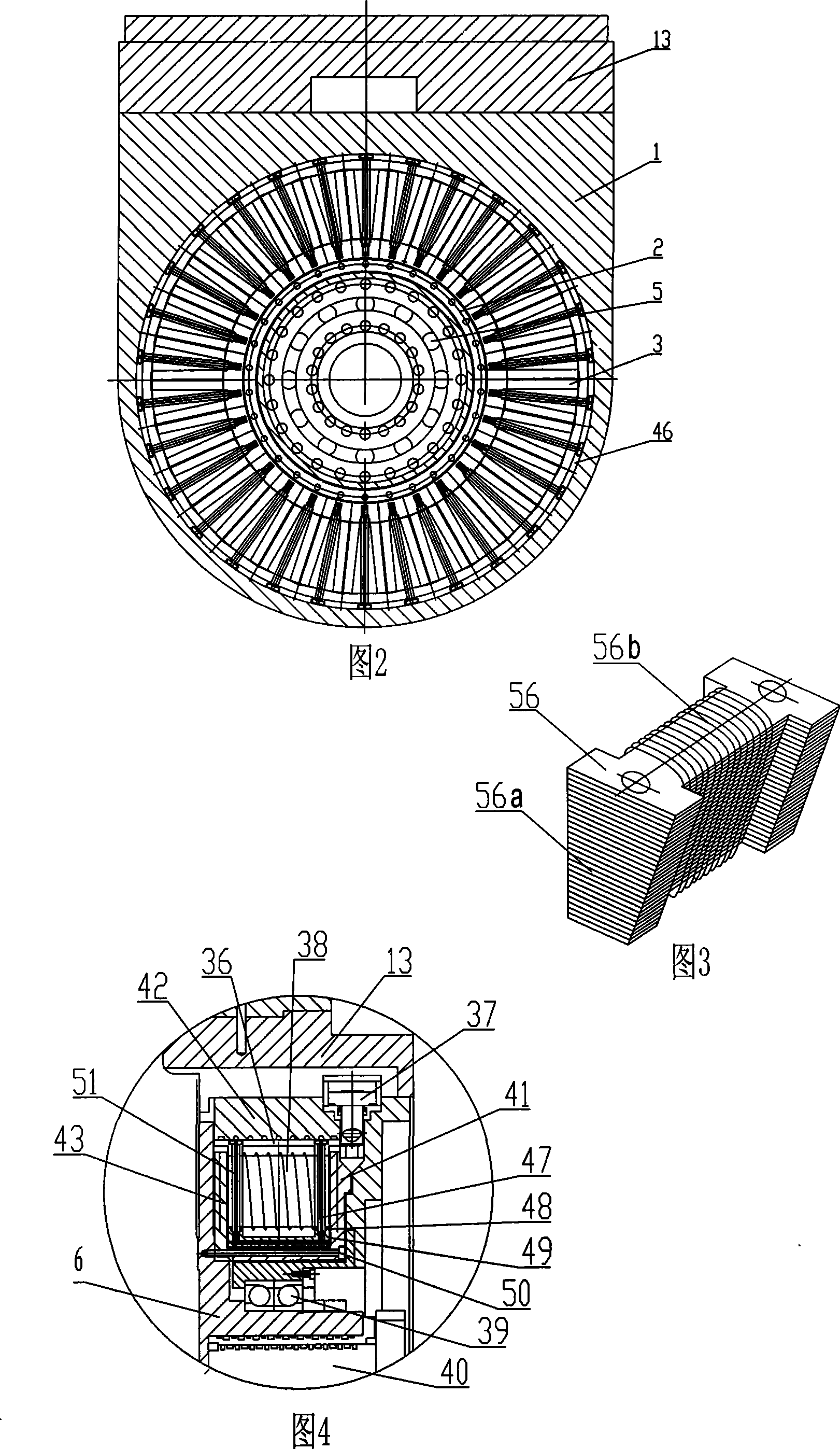

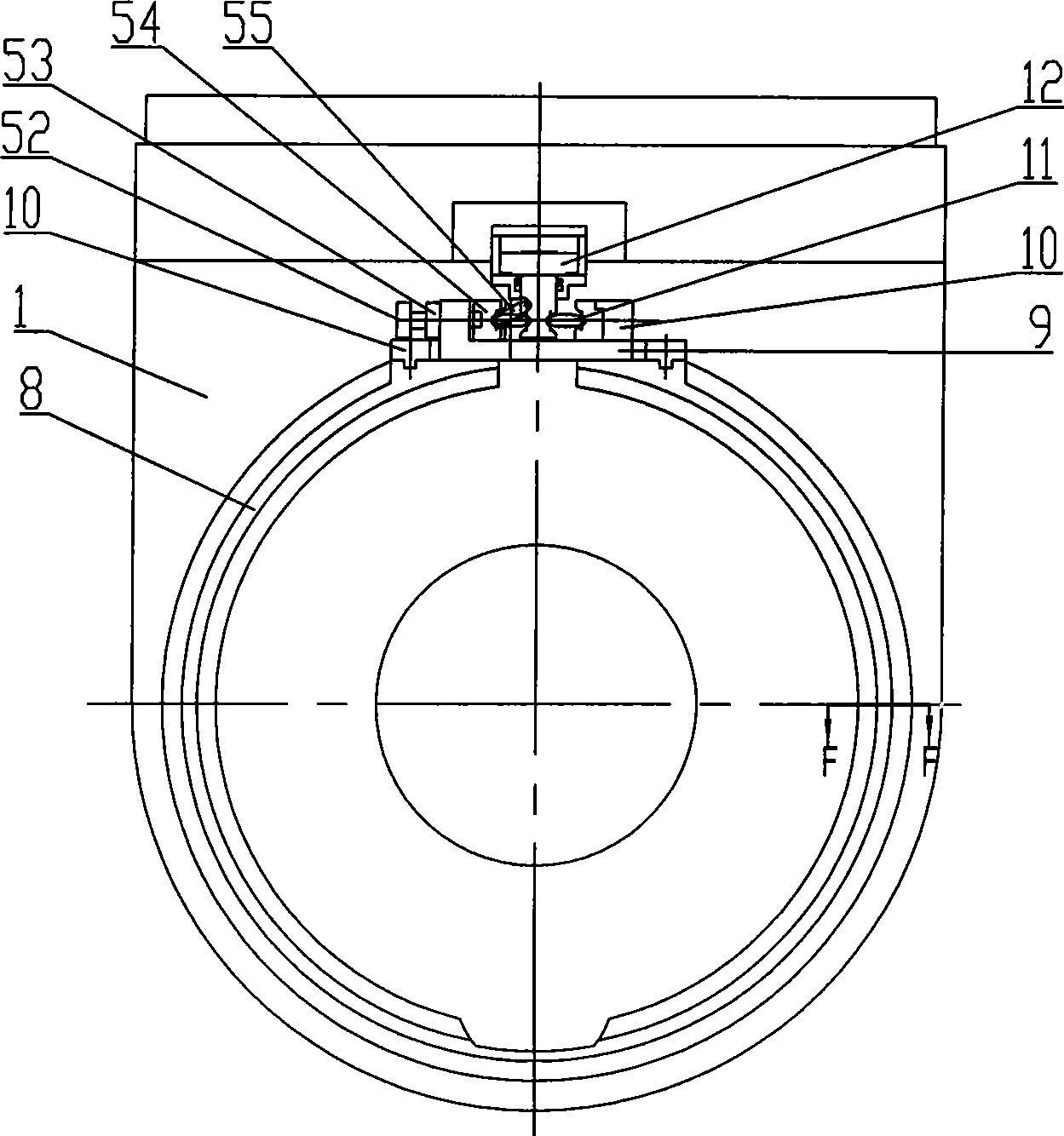

[0028] figure 1 A cross-sectional view of a high-torque double pendulum milling head driven by an AC permanent disk torque motor is shown. The high-torque double pendulum milling head is composed of a C-axis part and an A-axis part, and is mounted on a CNC machine tool ram through a turntable support seat 16 with bolts. The A-axis part can rotate around the axis of the C-axis, and the main shaft 44 can rotate around the axis of the A-axis, so that the main shaft can rotate around the A-axis and the C-axis. It provides a good functional component for the five-coordinate linkage of the machining center, and becomes a symbolic component reflecting the advanced technology of modern high-end CNC machine tools.

[0029]The fixed sleeve 20 of the C-axis part is connected to the turntable support seat 16 with bolts, and the double disc type torque motor of the C-axis is housed inside it, and the first stator iron core 18 is housed in the first stator cover 34. The second stator core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com