Tissue clamping part of linear cutting stapler and its staple cartridge seat

A stapler and tissue clip technology, applied in the field of medical devices, can solve the problems of complex structure of the staple magazine and the nail anvil, high processing cost of the nail magazine and the nail anvil, and achieve the effect of stable tissue, not easy to slip off, and stable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

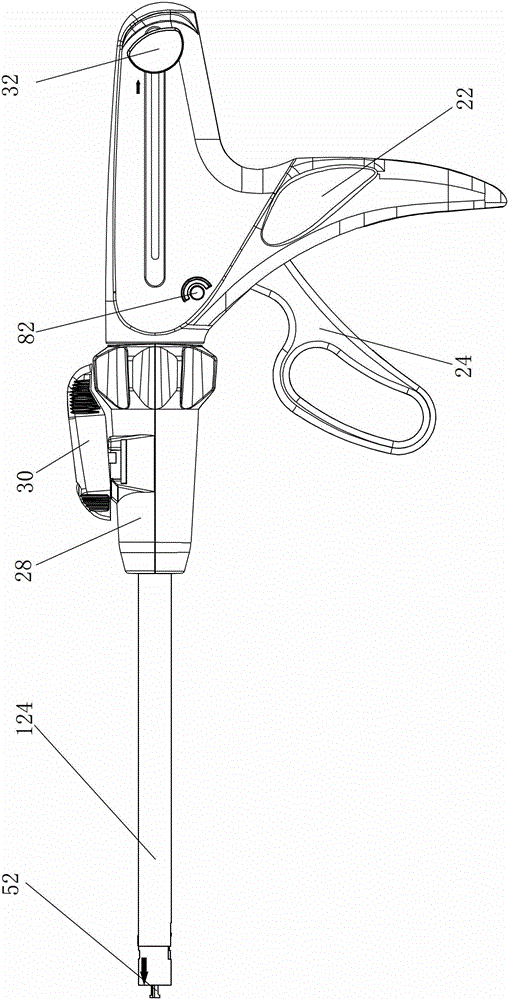

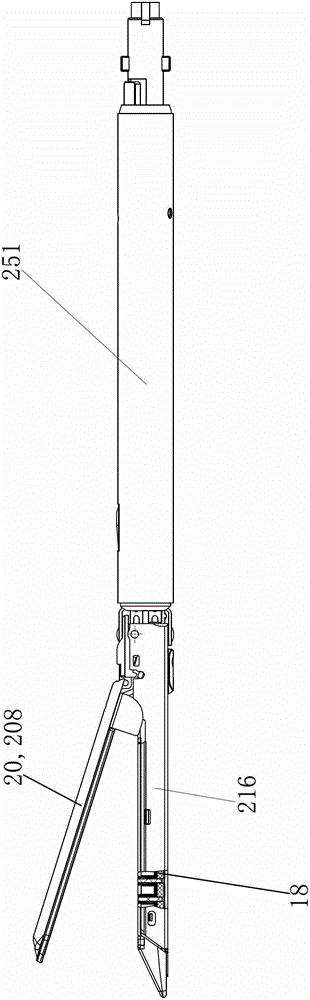

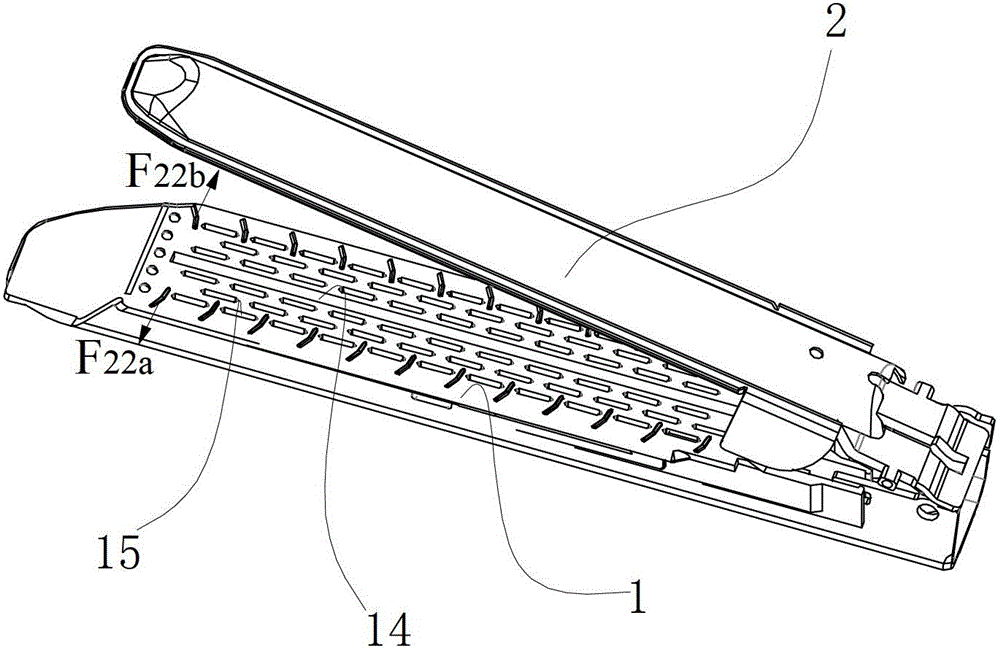

[0059] See image 3 , The tissue clamping part of the linear cutting stapler of this embodiment is composed of a staple cartridge assembly and an abutment seat assembly. The staple cartridge assembly includes a staple cartridge seat 1 , and the nail abutment seat assembly includes a nail abutment seat 2 . The nail bin seat 1 is an integral part of injection molding, and the nail abutting seat 2 is an integral part made of steel.

[0060] The above-mentioned tissue clamping part is mainly composed of a staple cartridge assembly and an anvil seat assembly. In the cartridge assembly, in addition to the cartridge holder 1, the cartridge assembly 18 in US Patent No. 5,865,361 is used. In the nail anvil assembly, the nail anvil assembly 20 in US Patent No. 5,865,361 is used outside the nail anvil 2 .

[0061]The staple cartridge seat 1 includes a staple ejecting surface 11 , a push knife groove 14 and a staple ejecting hole 15 . The nail-exiting surface 11 is arranged along a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com