Steel plate punching clamping mechanism

A clamping mechanism and punching technology, applied in the direction of feeding device, manufacturing tool, positioning device, etc., can solve the problems of infirmity, inaccurate punching position, troublesome fixing, etc., achieve good effect, accurate punching, clamping hold firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

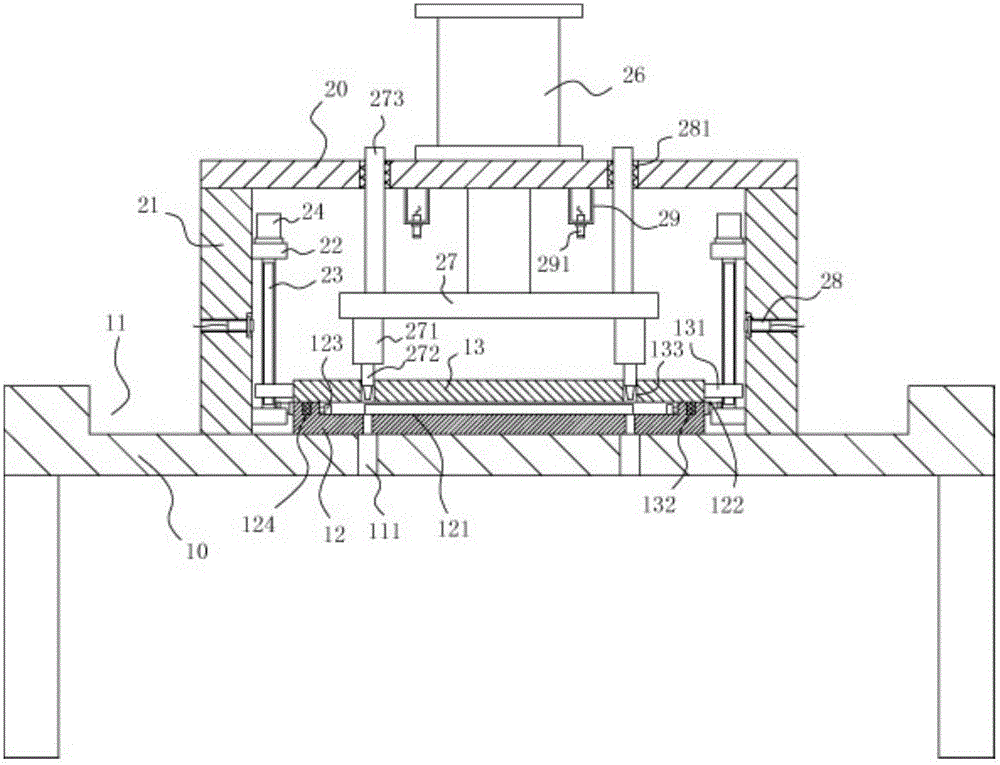

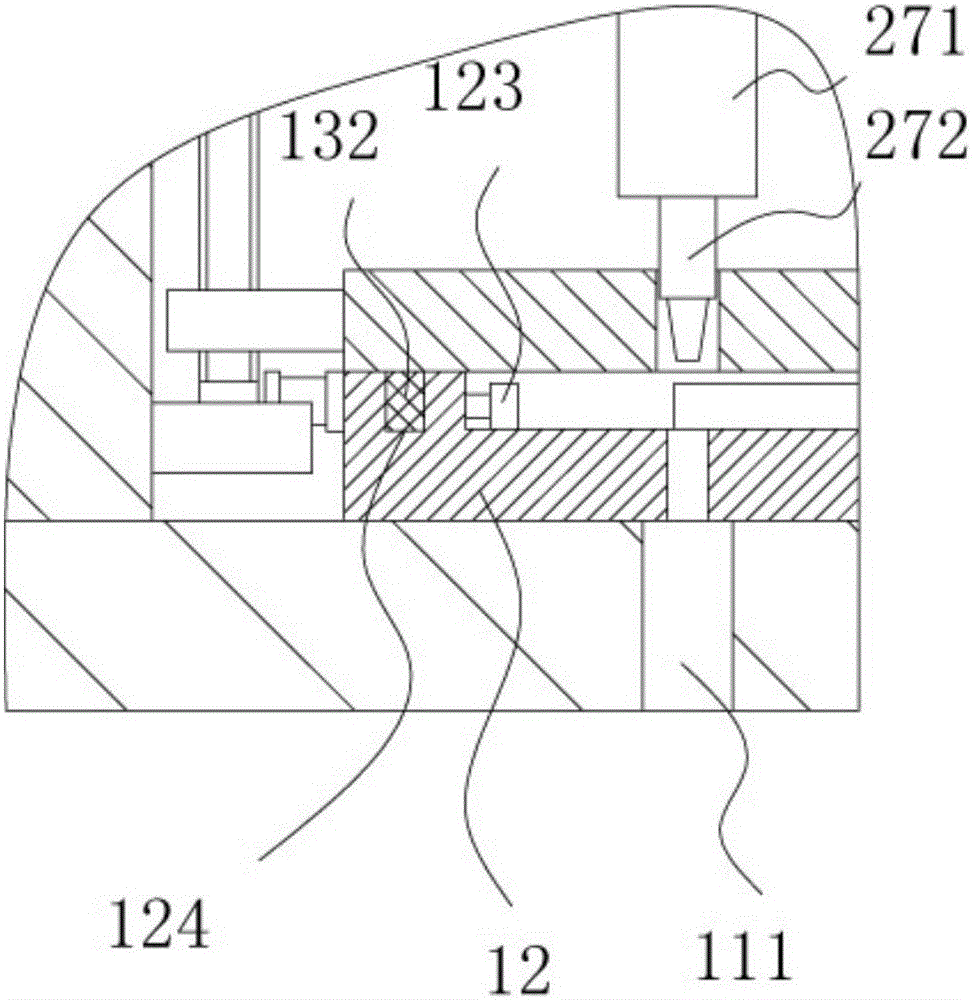

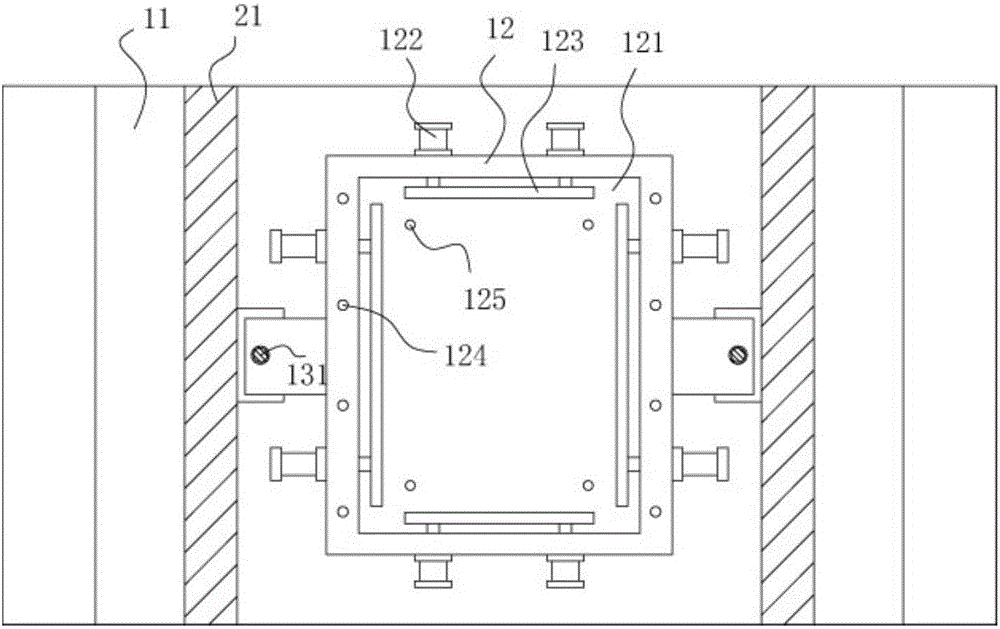

[0017] Example: see Figure 1 to Figure 3 As shown, a steel plate punching and clamping mechanism includes a frame 10, the top surface middle part of the frame 10 has a main groove 11, the middle part of the main groove 11 is fixed with a bottom placement block 12, and the bottom placement block 12 There is a placement groove 121 in the middle, and a push cylinder 122 is fixed on the four outer sidewalls of the bottom placement block 12, and the push rod of the push cylinder 122 extends into the placement groove 121 and is fixed on the corresponding clamping plate 123, clamping The plate 123 is parallel to the corresponding inner side wall of the placement groove 121, the main connecting frame 20 is fixed on the bottom surface of the main groove 11, and the upper and lower parts of the inner side walls of the two vertical support plates 21 of the main connecting frame 20 are fixed with Connecting plate 22, the two ends of transmission screw rod 23 are hinged on two connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com