High-concentration pulping machine

A high-consistency refiner and casing technology, applied in pulp beating/refining methods, textile and papermaking, fiber raw material processing, etc., can solve the problems of low physical indicators such as tensile strength, mill clogging, and high pulp concentration , to achieve the effect of improving the quality of the end product, increasing the tensile strength, and increasing the beating concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

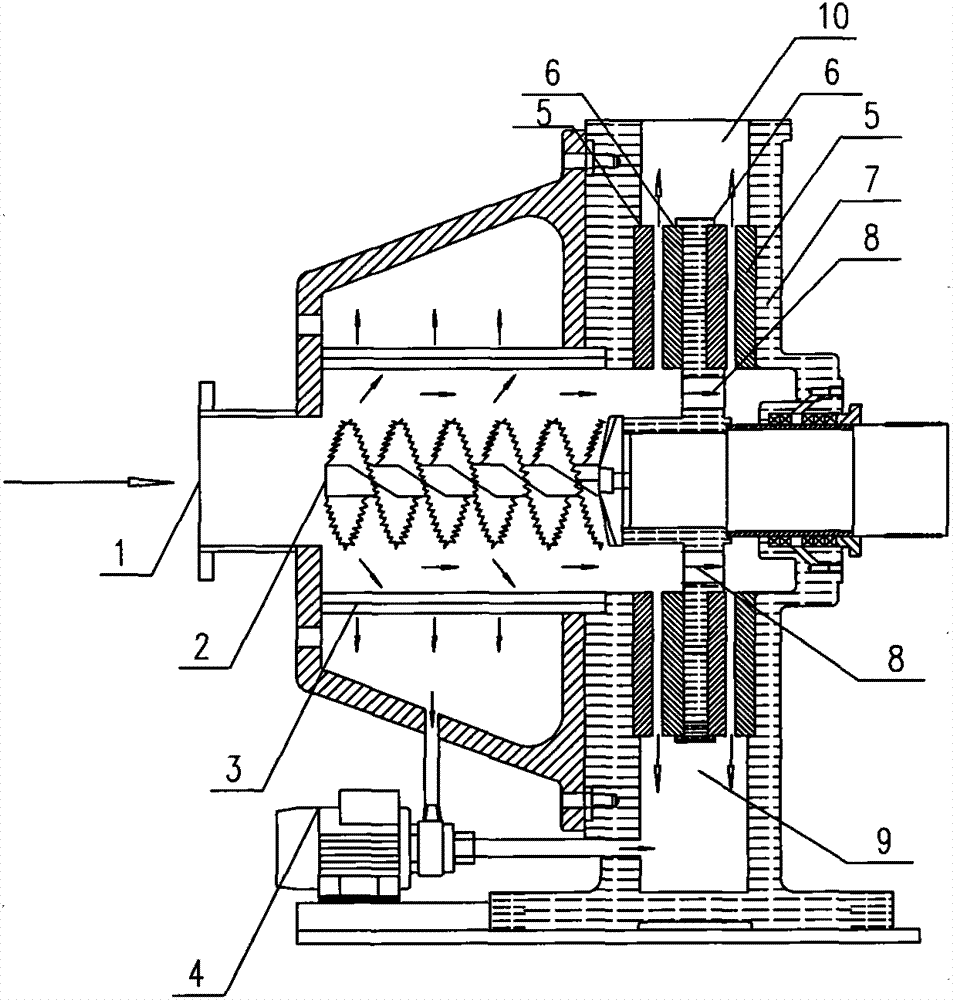

[0017] A high-consistency refiner, comprising a casing 10, a dewatering screen drum 3, a conveying impeller 2, a grinding shell 7, and a grinding disc 12, wherein the conveying impeller 2 includes a drive shaft and a helical blade fixedly connected to the drive shaft, and the conveying impeller 2 It is located in the dehydration screen drum 3, and the dehydration screen drum 3 is located in the casing 10; an opening is provided on the casing 10 as a pulp inlet 1, and the position of the pulp inlet 1 corresponds to the front end of the conveying impeller 2, thereby dehydrating The screen drum 3 communicates with the outside of the casing 10 through the slurry inlet 1; the casing 10 is also provided with a connection port of the grinding casing 7, and the grinding casing 7 communicates with the casing 10 through the connection port of the grinding casing 7. Inside the grinding casing 7, there is a Grinding disc 12, which is coaxially connected with the delivery impeller 2, the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com