Glass product sweeping device and method

A product, glass technology, applied in the field of glass product sweeping equipment and light sweeping, can solve the problems of not in place, foaming of grinding water, uneven sweeping, etc., to achieve improved production efficiency, high yield, and smooth sweeping high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

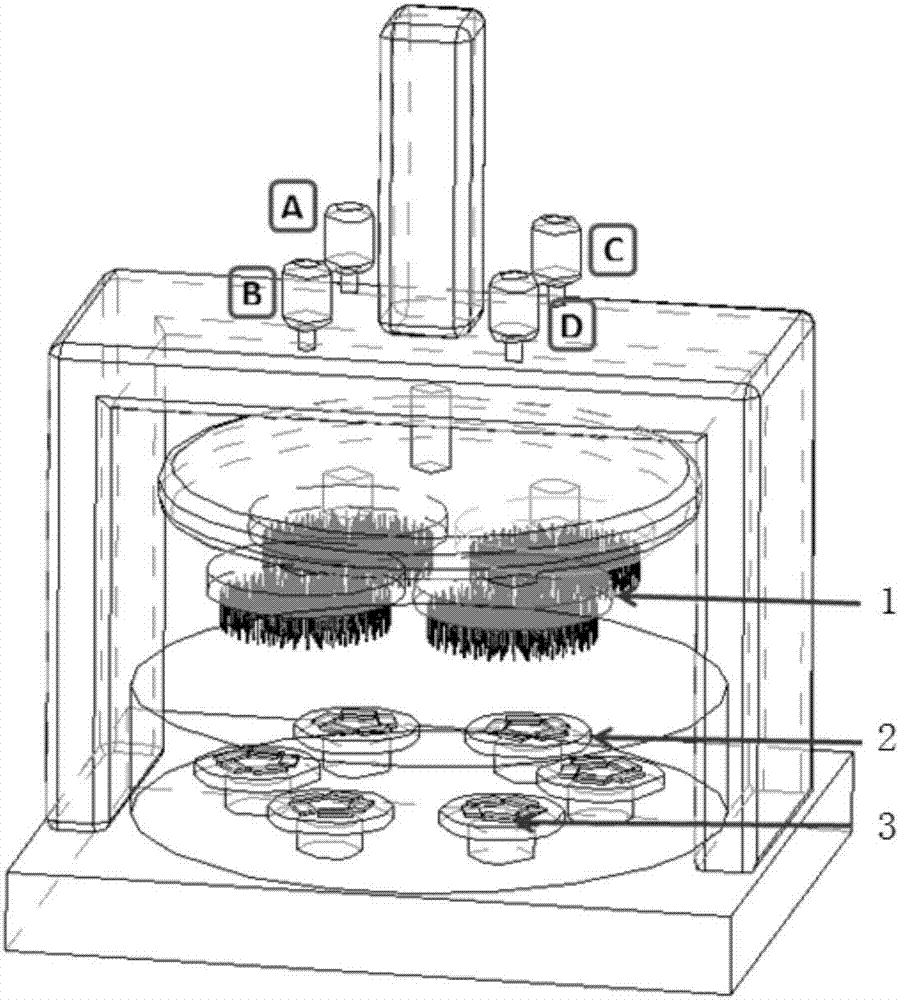

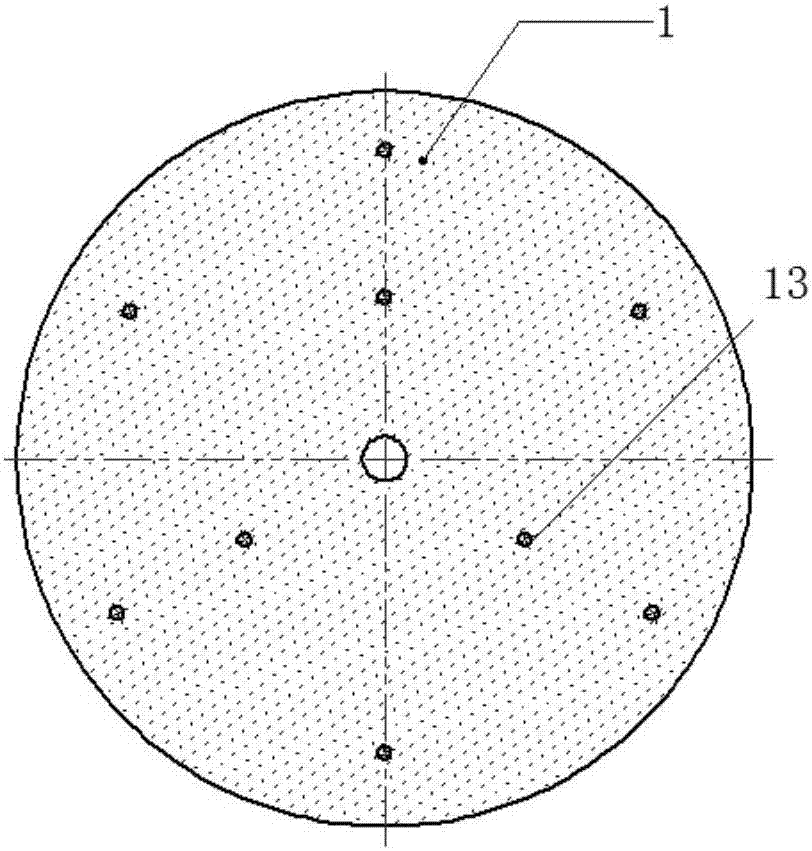

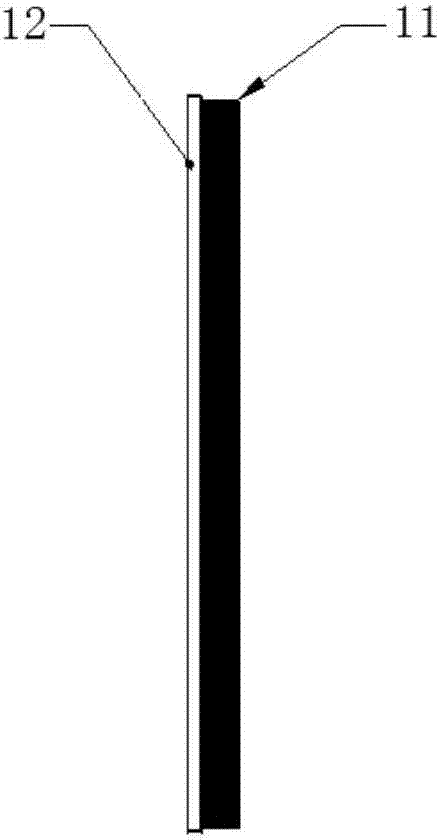

[0026] refer to figure 1 , in one embodiment, a kind of optical scanning equipment for glass products, comprising at least one upward scanning optical disc 1 and a plurality of lower bearing discs 2 arranged below the upper scanning optical disc 1, each lower bearing disc 2 is equipped with multiple A product placement tray 3, the upper scanning optical disc 1 is driven to rotate by an upper drive motor, and the plurality of lower carrier trays 2 are driven by different lower drive motors to rotate independently of each other, and the products to be scanned are placed on the The product is placed on the tray 3, and the upper scanning optical disc 1 has bristles 11. During the rotation, the upper scanning optical disc 1 moves relative to the plurality o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com