High-cleanness automatic compensation type sweeper

An automatic compensation and cleaner technology, which is applied in the field of cleaners, can solve problems such as unclean cleaning, simple structure, and conveyor belt deviation, and achieve remarkable cleaning effect, good cleaning effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

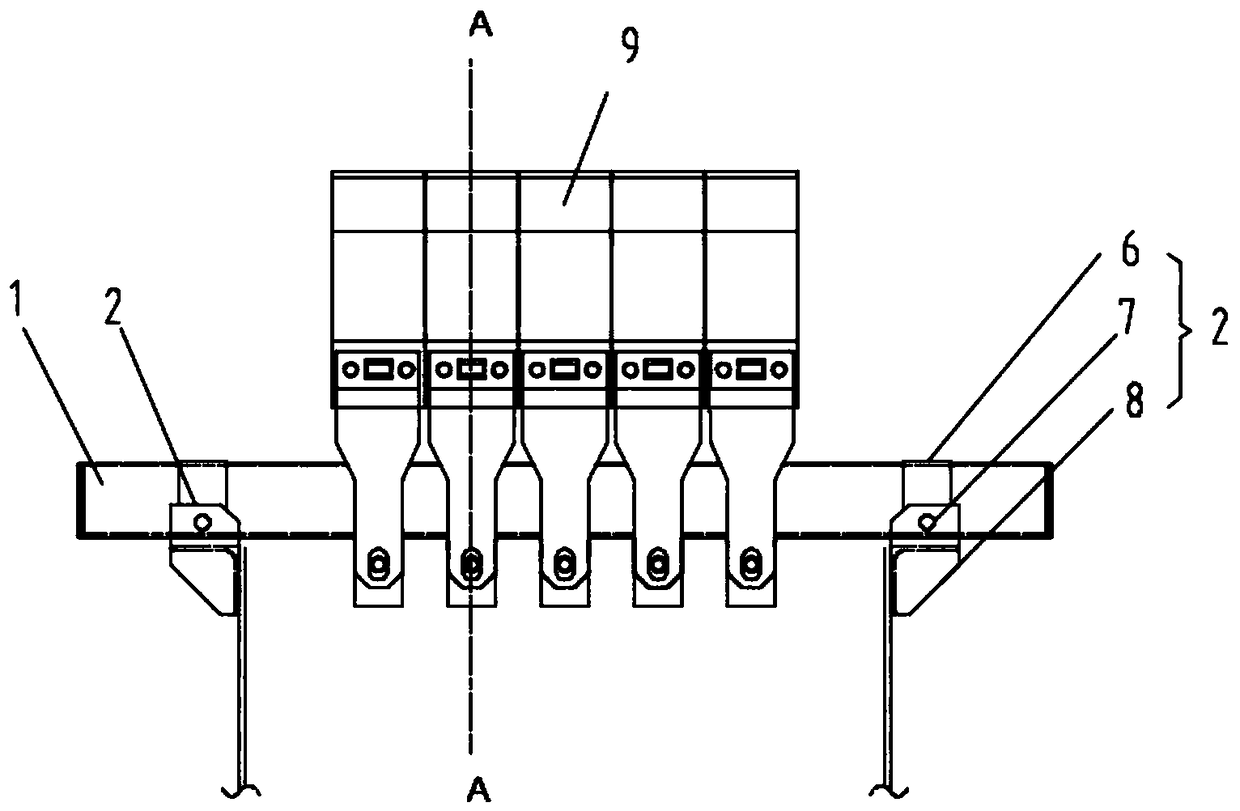

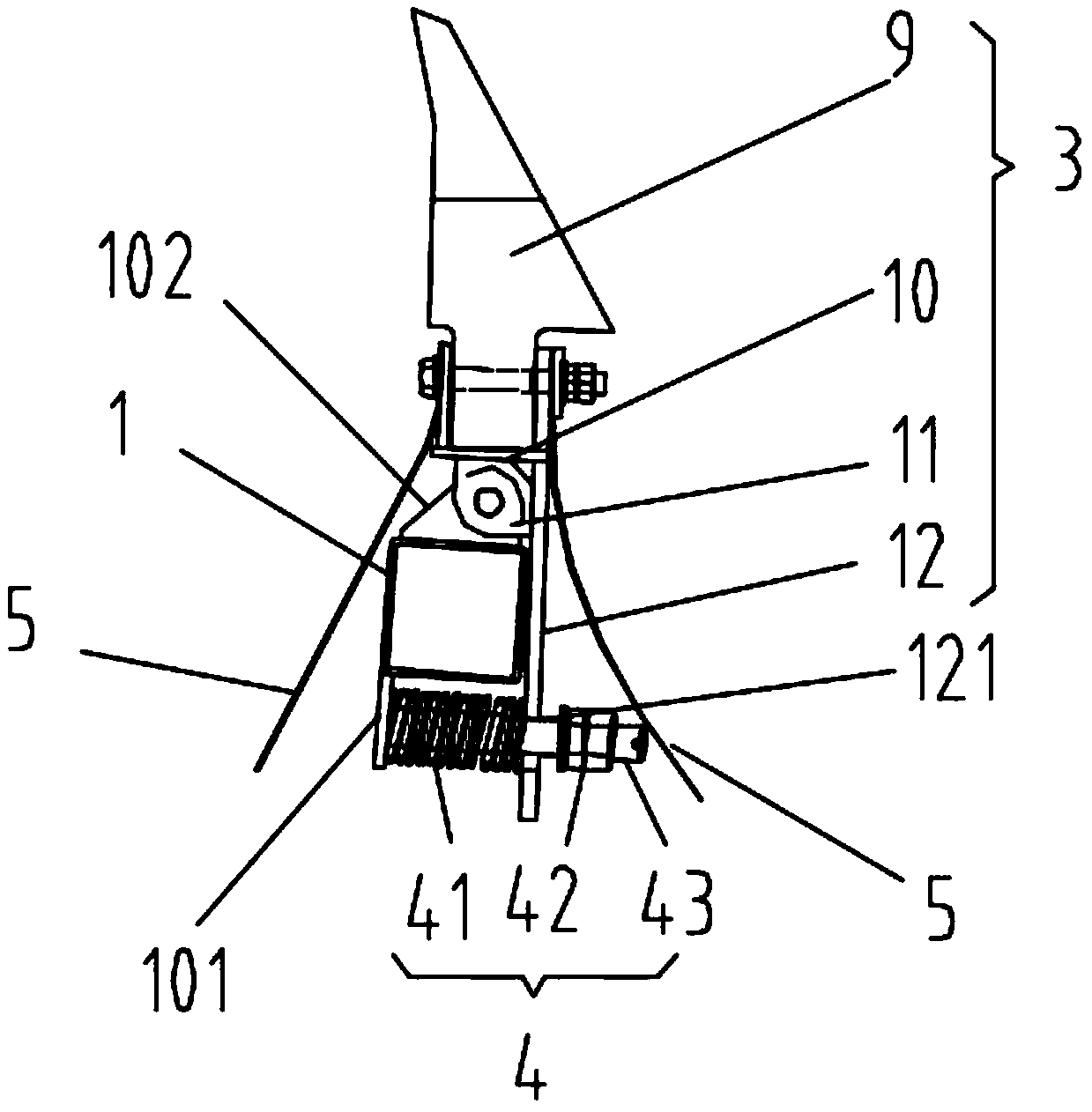

[0025] Such as Figure 1 to Figure 4 As shown, a high-cleanliness automatic compensation type cleaner described in this embodiment includes a beam 1, the left and right ends of the beam 1 are fixedly equipped with fixing seats 2, the upper surface of the beam 1 is equipped with a scraper mechanism 3, the beam 1 The lower surface of 1 is fixedly equipped with a spring compensation adjustment mechanism 4, and the lower end of the scraper mechanism 3 is connected with the spring compensation adjustment mechanism 4.

[0026] The beam 1 is fixed on the external equipment through the fixing seat 2, so that the scraper mechanism 3 is in contact with the surface of the conveyor belt, and the spring compensation adjustment mechanism 4 can make the scraper mechanism 3 always in good contact with the surface of the conveyor belt, thereby achieving a better sweeping effect.

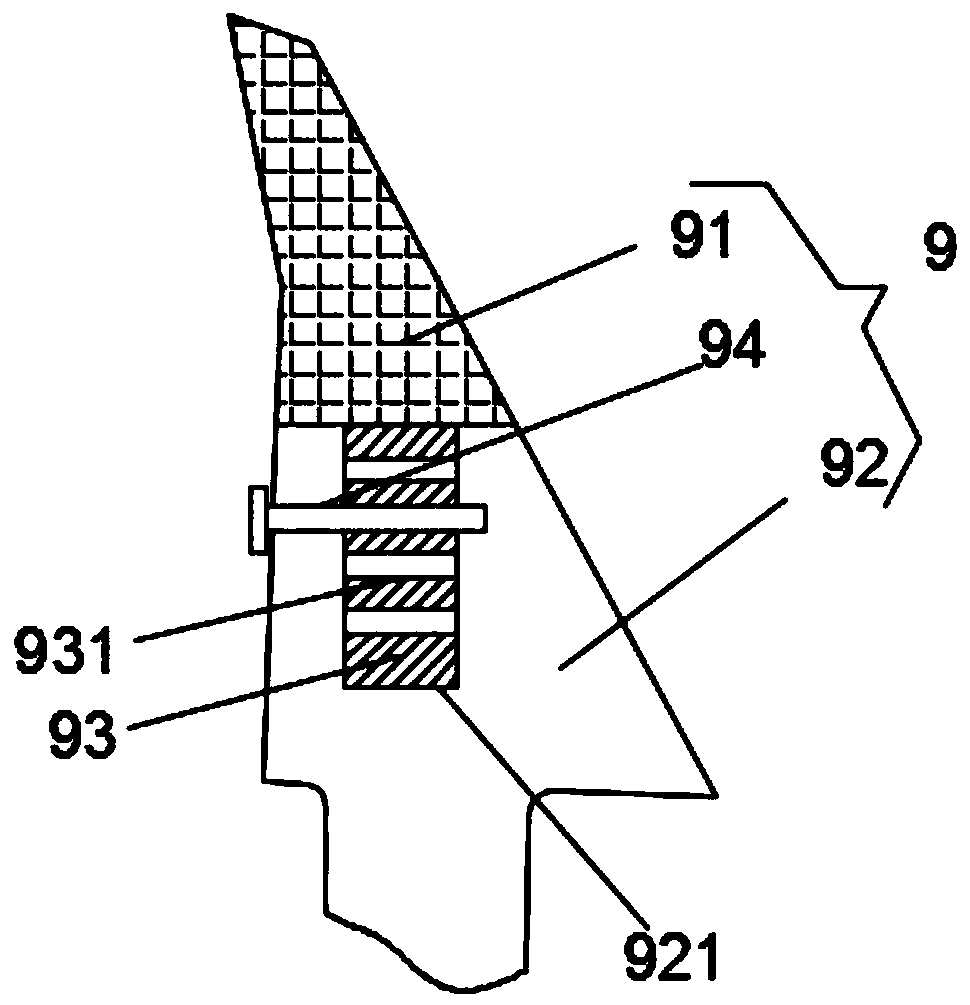

[0027] The scraper mechanism 3 includes a scraper 9 and a scraper mounting base 10, the scraper 9 is fixedly mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com