Brooming device for upper surface of prefabricated laminated slab

A technology of stacking plates and sweeping hair, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of low efficiency, difficult to guarantee quality, and high cost of chemical treatment methods, and achieve the goal of improving work efficiency, strong adaptability, and achieving continuity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

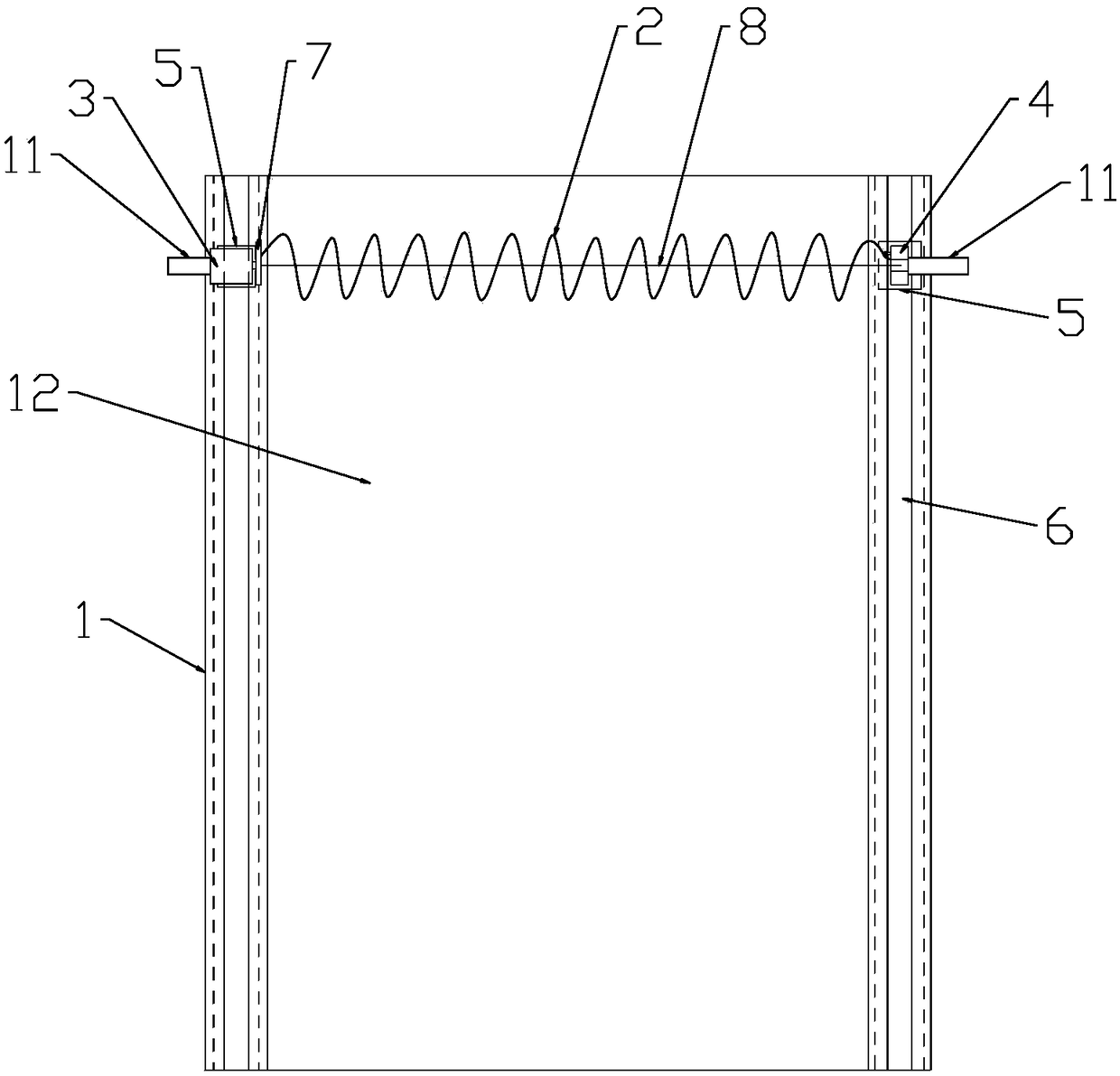

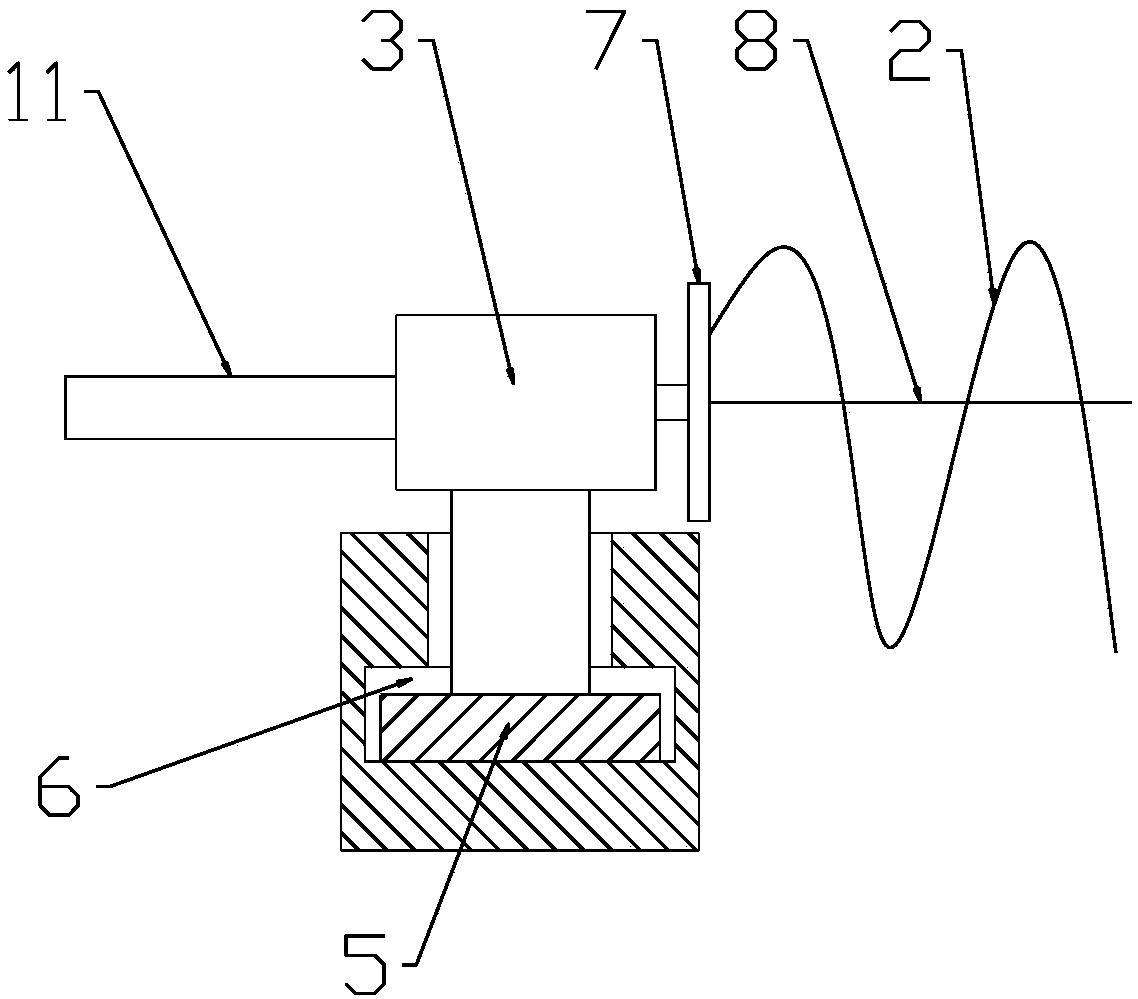

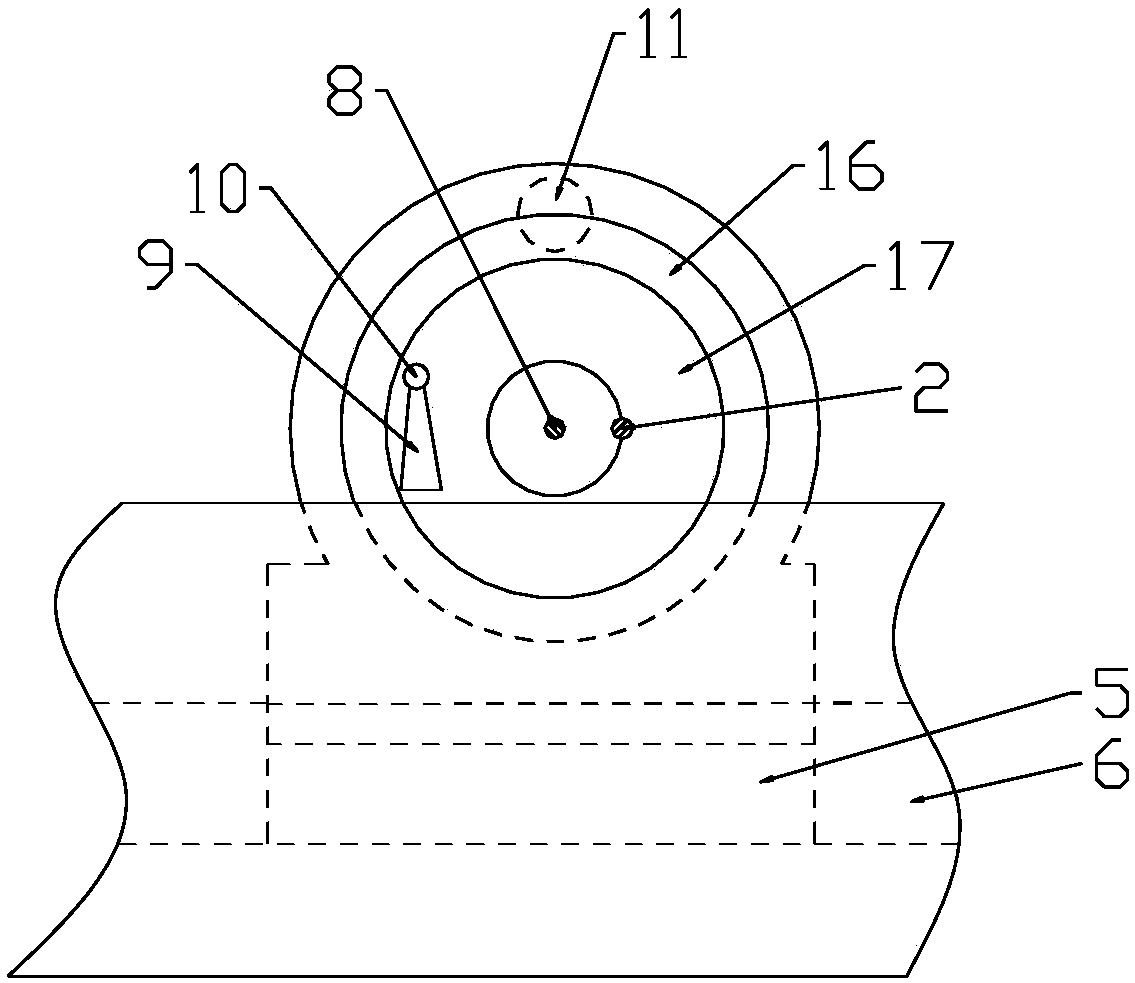

[0025] Such as Figure 1 to Figure 4 As shown, a device for sweeping the surface of a prefabricated laminated board includes a walking track 1 and a sweeping assembly. There is a chute 6, the groove of the running track is parallel to the surface of the prefabricated laminated board 12, and the brushing assembly includes a tension spring 2 located between the running rails 1, and the tension spring 2 is in contact with the surface of the prefabricated laminated board 12, and the two walking A traveling device that can walk along the chute 6 is respectively provided on the track 1. The main driving device and the driven device are respectively installed on the two traveling devices. The two ends of the extension spring 2 are respectively connected with the main driving device and the driven device. The driving device includes a motor 3, the driven device includes a bearing one 4, and the running device on the two running rails 1 is respectively a slider 5 fixed on the lower par...

Embodiment 2

[0030] Such as Figure 5 , Image 6 As shown, a prefabricated laminated board surface sweeping device, wherein, including a walking track 1 and a sweeping assembly, the walking track 1 is two, and the sweeping assembly includes a tension spring 2 between the walking tracks 1, and the walking track 1 A walking device that can walk along the walking track 1 is respectively arranged on the top, and a driving device that drives the extension spring 2 to rotate is installed on the walking device, and the two ends of the extension spring 2 are respectively connected with the corresponding driving device.

[0031] Driving device comprises bearing two 13, and traveling device comprises the roller 14 that is sleeved on the bearing two 13, and roller 14 is positioned at the chute 6 that establishes on the walking track 1, and the outer ring of roller 14 and bearing two 13 is rotationally connected, and extension spring The two ends of 2 are respectively fixedly connected with the outer r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com