Cleaning device for insulator

A technology for cleaning devices and insulators, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of electric shock hazard, manual cleaning efficiency cannot meet requirements, manual cleaning cannot ensure effective safety distance, etc., to prevent dust from flying. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

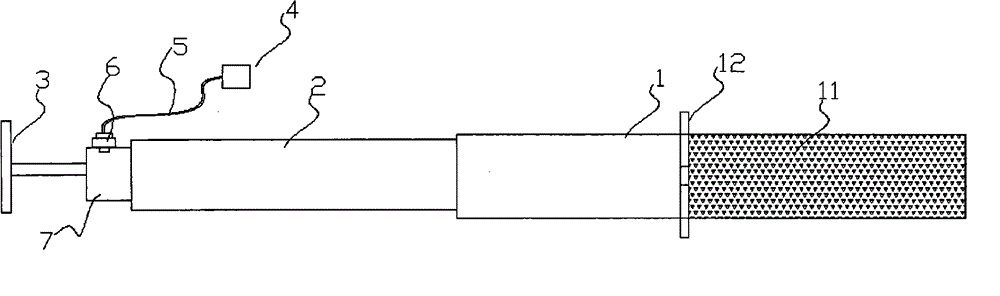

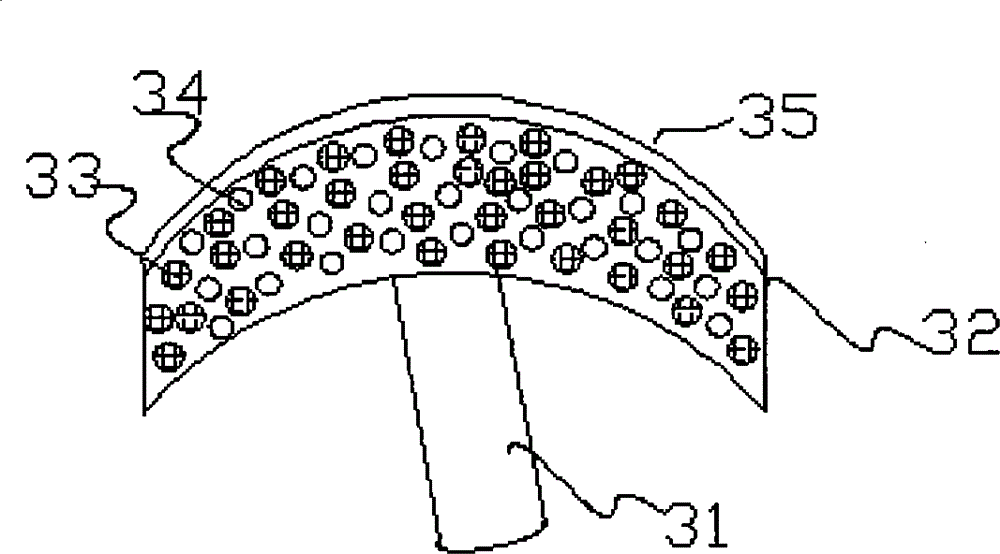

[0013] see figure 1 , 2, an insulator cleaning device, including a telescopic rod, the telescopic rod includes a first rod body 2 and a second rod body 1, and the first rod body 2 is movably socketed on the second rod body 1 through a rotating telescopic control device Inside, the front end of the first rod body 2 is detachably connected with a hollow T-shaped frame 3, the T-shaped frame includes an arc-shaped plate 32 with a cavity inside, connected with a hollow tube 31, the arc The inner arc surface of the shaped plate 32 is planted with bristles 33, and the outer arc surface 35 is glued with a cleaning sponge or cleaning cloth. The bristles 33 are provided with suction holes 34. The cavity of the arc-shaped plate is connected to the air pipe 5 , and the other end of the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com