Loom convenient to move and provided with dust collecting system

A dust collection system and textile machine technology, applied in the field of textile machinery, can solve problems affecting product quality, low dust collection efficiency, dust flying, etc., to achieve the effects of avoiding secondary dust, reducing dust cleaning load, and high dust collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

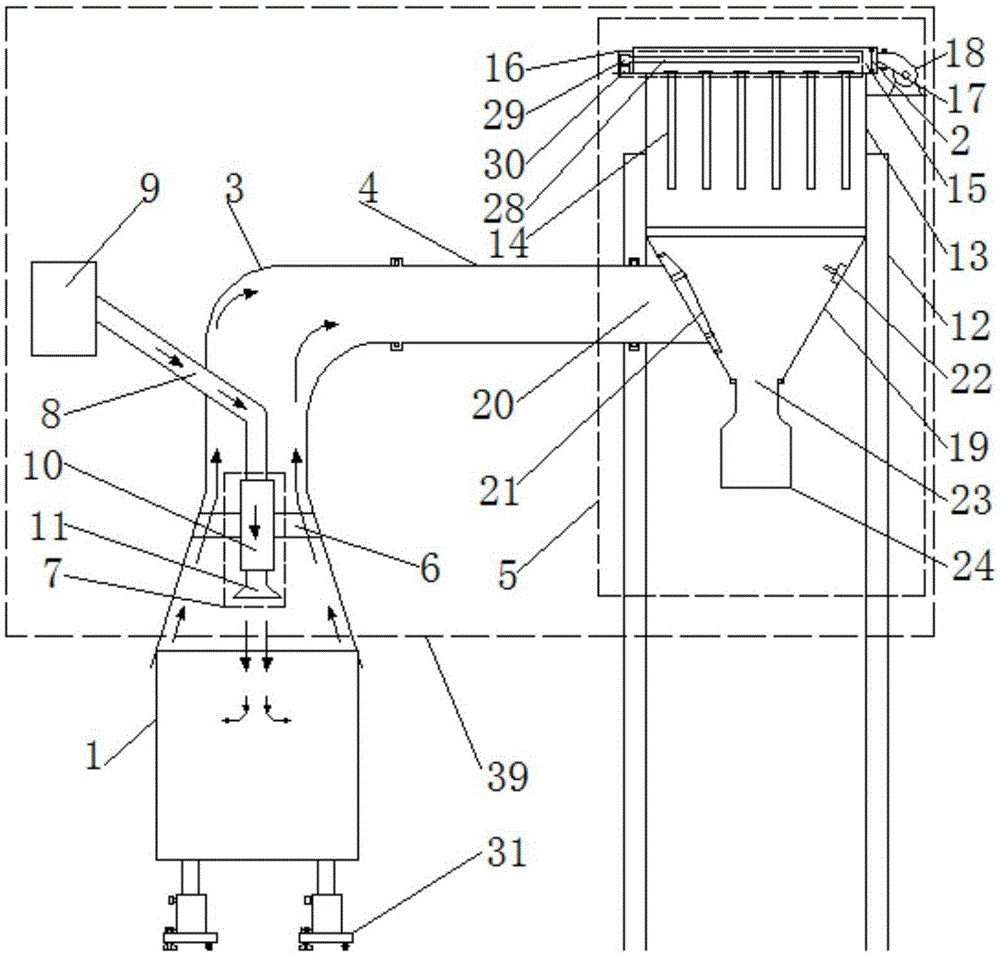

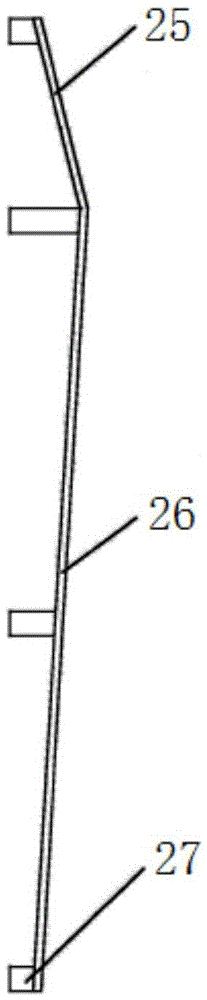

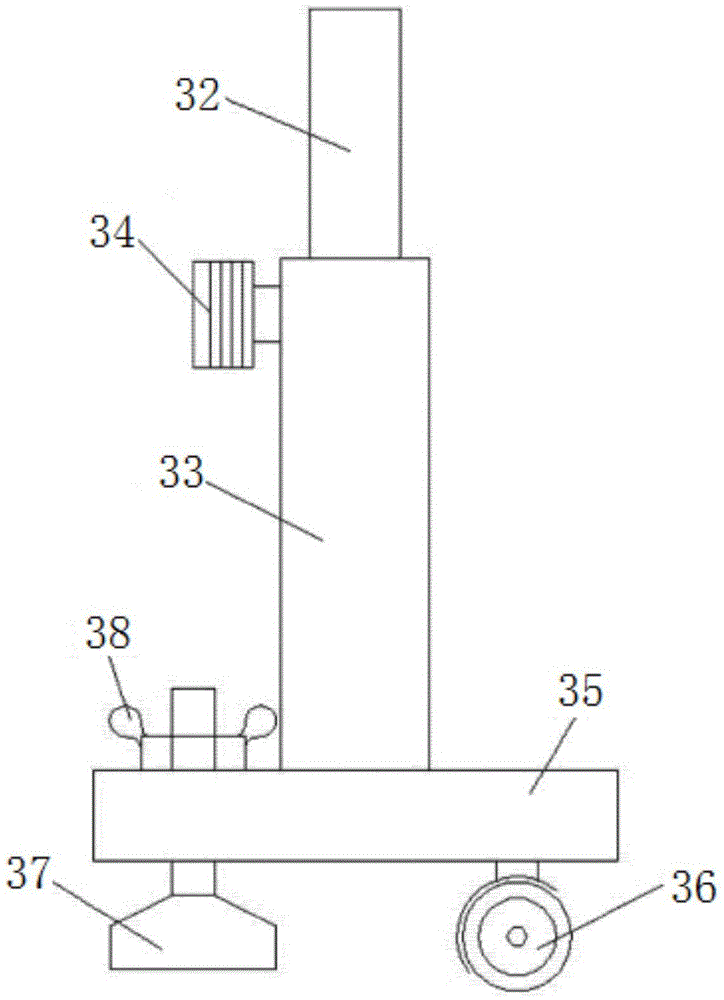

[0020] Example. A textile machine that is easy to move and has a dust collection system, constituted as figure 1 , figure 2 with image 3 As shown, the textile machine 1 is included, and the bottom of the textile machine 1 is provided with a support mechanism 31; the support mechanism 31 includes a support rod 32, and the support rod 32 is arranged on the bottom of the textile machine 1, and the support rod 32 is provided with a sleeve 33, Support rod 32 telescopically is arranged in sleeve pipe 33, and the top of sleeve pipe 33 is provided with fastening bolt 34, and the bottom of sleeve pipe 33 is provided with cross bar 35, and one end of cross bar 35 is provided with universal wheel 36, and the end of cross bar 35 The other end is provided with support foot 37, and support foot 37 is threade...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com