Dust collection electrode back-flushing filtering electrostatic precipitator

A dust collecting pole and electrostatic precipitator technology, applied in electrostatic separation, electrode structure, electrode cleaning, etc., can solve the problems of increasing the resistance of the dust collector, reducing the advantages of equipment, and not being able to solve the problem of dust removal well, so as to improve the dust removal efficiency , Solve the effect of secondary dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

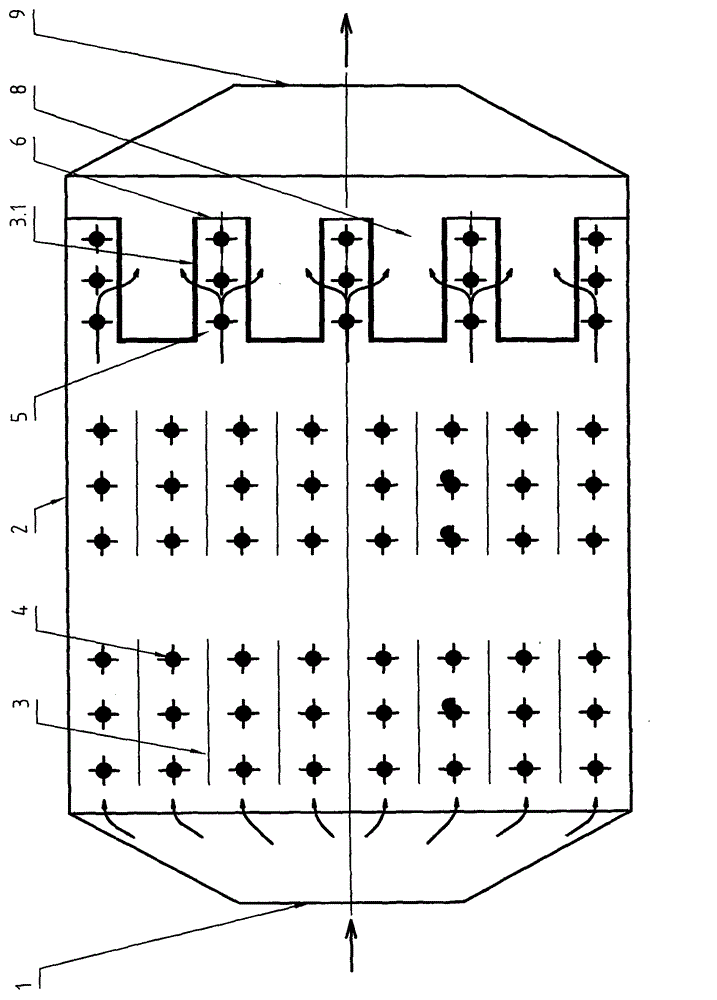

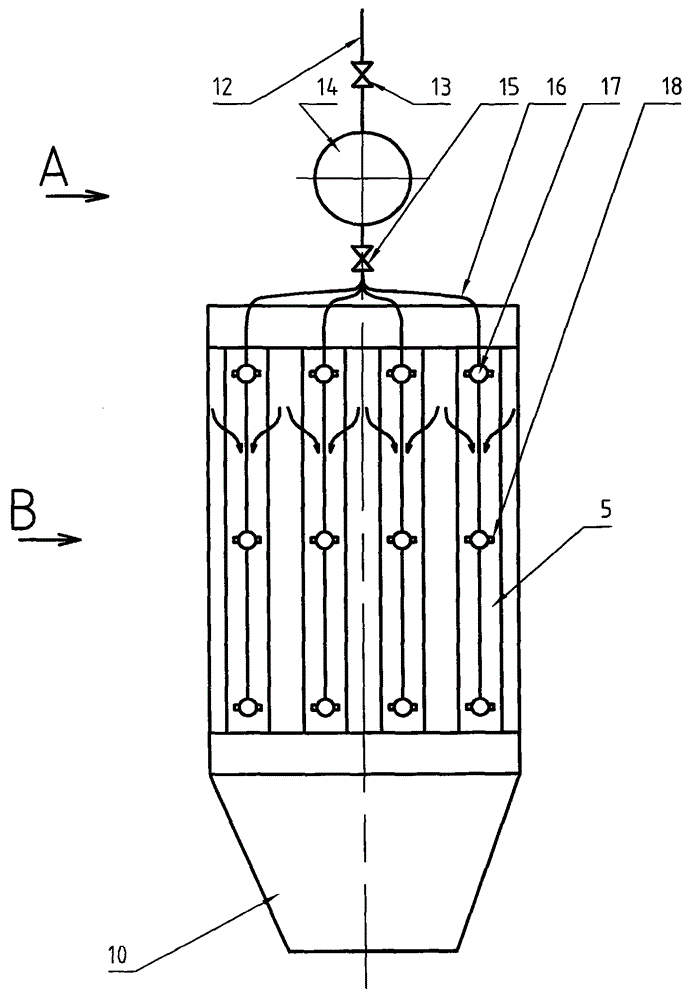

[0037] Example 1, such as Figure 1 to Figure 6 shown.

[0038] The dust-collecting electrode blowback filter electrostatic precipitator of the present invention comprises gas inlet 1, housing 2, anode 3, cathode 4, gas outlet 9, ash hopper 10, power supply system 11 etc.; Anode 3 is plate-type dust-collecting electrode (comprising C-shaped plate, Z-shaped plate, etc.), there are multiple anodes 3 along the length direction of the shell 2, and there are multiple rows of anodes 3 along the width direction of the shell 2, and cathodes 4 are arranged between the anodes 3; the high-voltage power supply system supplies the anodes 3 and The cathode 4 supplies power; the anode 3 and the cathode 4 are fixed on the frame of the housing 2 through a hanging device (not shown).

[0039] The anode constitutes the dust collection pole, and in the direction of the flow of the dust-laden gas, at least a part of the dust collection pole at the rear of the anode 3 is a mesh dust collection pol...

Embodiment 2

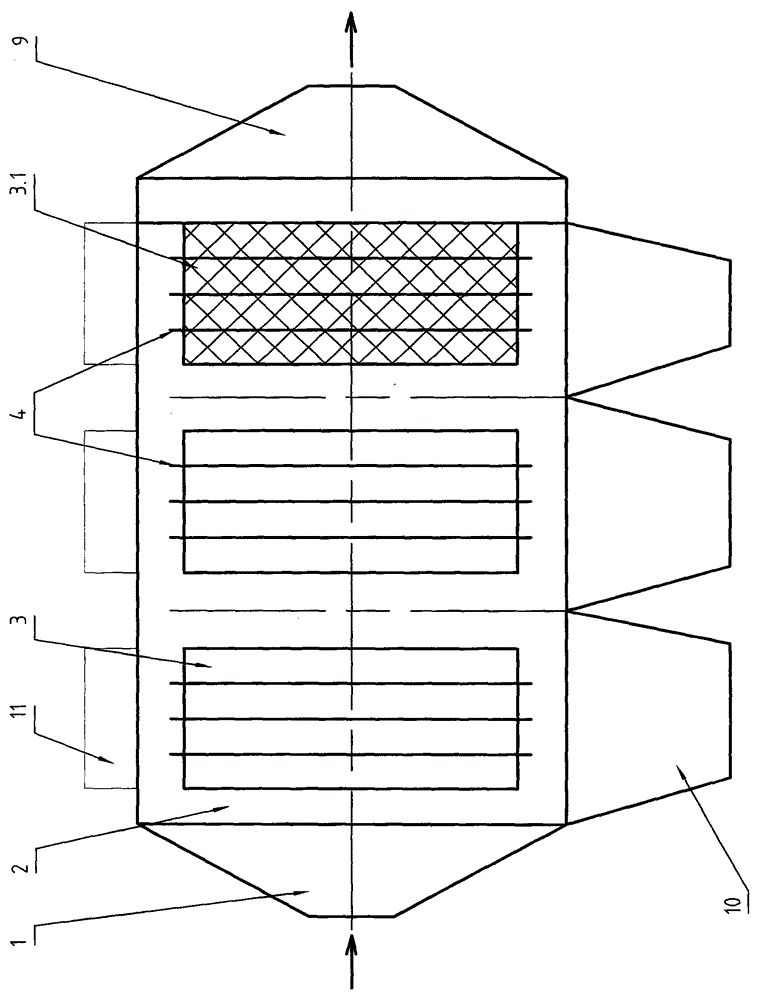

[0044] Example 2, Figure 7 shown.

[0045] This embodiment is a change carried out on the basis of Embodiment 1, the difference is:

[0046] In the flow direction of the dusty gas, all the dust collecting poles are mesh dust collecting poles 3.1. In the width direction of the casing 2, there are two rows of mesh dust collecting poles 3.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com