Dry method dust-free dust discharging system

A dust and dry process technology, applied in the field of dry dust-free ash unloading system, can solve the problems of secondary dust, generate a large amount of steam, large drop of ash discharge, etc., to solve the problem of secondary dust, improve the working environment and application prospects. expansive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

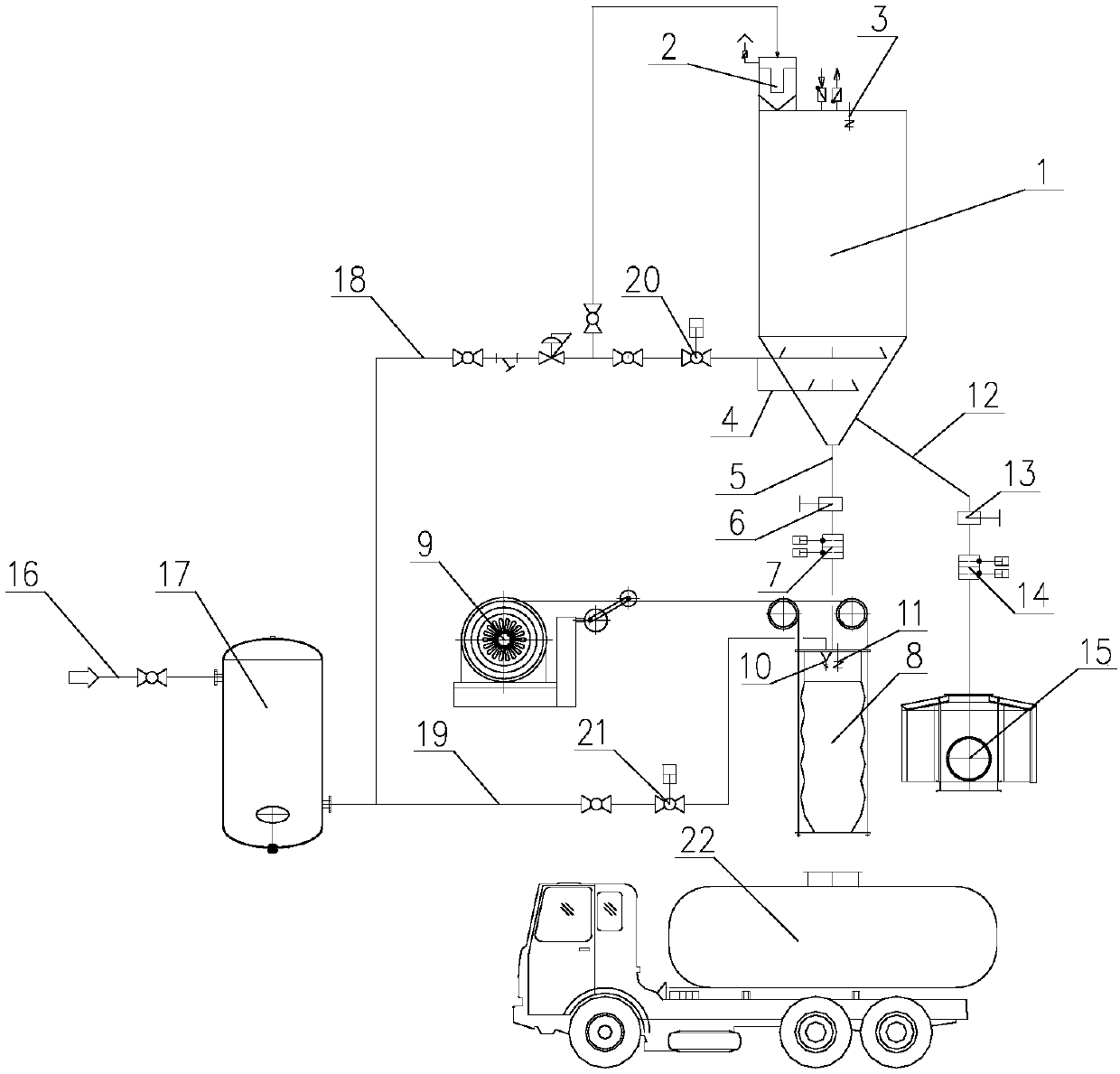

[0020] Such as figure 1 As shown, the dry dust dust-free ash unloading system of the present invention includes a coarse ash bin 1, an ash unloading main pipe 5, a telescopic metal hose 8, a winch 9, an accident ash unloading pipe 12 and a mobile accident ash bin 15.

[0021] The ash unloading port of the coarse ash bin 1 is connected with the telescopic metal hose 8 through the ash unloading main pipe 5, and the ash unloading main pipe 5 is provided with a manual plug valve 6 and a pneumatic double-layer flap valve 7.

[0022] The top of the coarse ash bin 1 is provided with a simple bag filter 2 and a first radar level gauge 3 . The simple bag filter 2 is used to collect the dust discharged from the top of the coarse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com