Coulomb electric precipitator

A technology of electrostatic precipitator and electric field, which is applied in the field of electromechanical, to achieve the effect of overcoming secondary dust, saving the overall cost, and breaking through re-flooding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

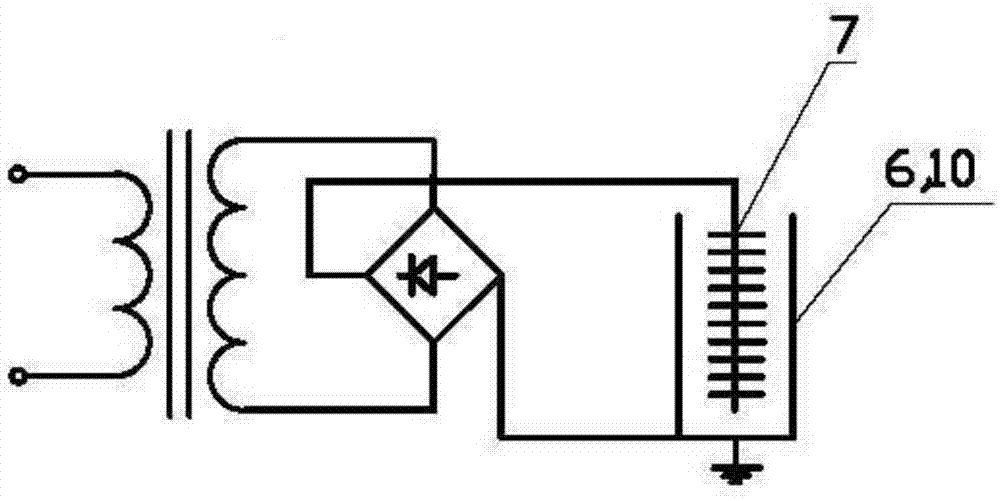

[0027] figure 1 It is the schematic diagram of the present invention, the negative end of the output of the high-voltage DC power transformer is electrically connected to the corona discharge electrode 7, the positive end of the output of the high-voltage DC power transformer is electrically connected to the dust collector such as the anode plate 6 or the housing 10 and grounded.

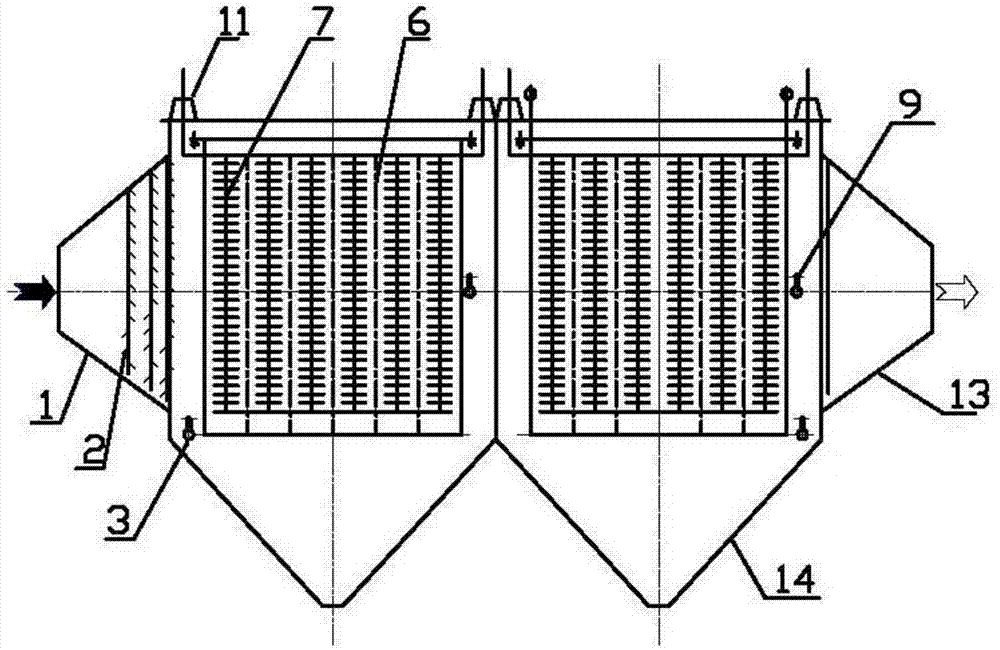

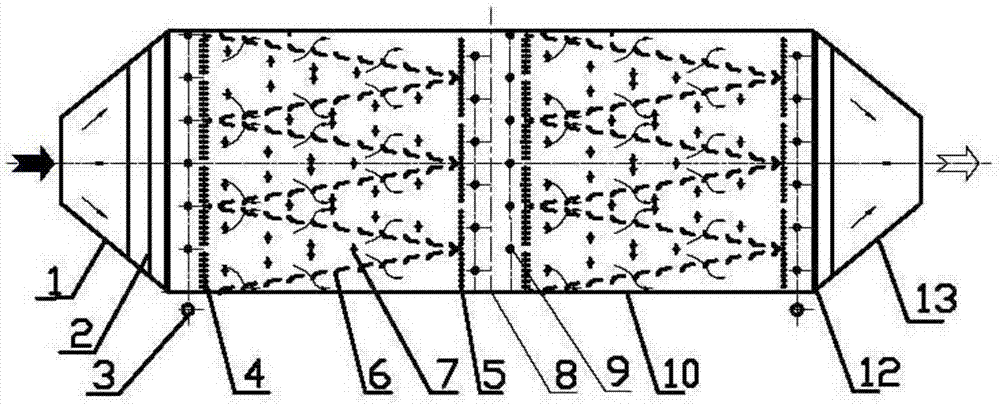

[0028] exist figure 2 Among them, for the overall structure of the present invention, the inlet distribution plate 2 is arranged in the inlet head 1, and the anode plate 6 is set to match the corona discharge electrode 7 in the Coulomb electric field, and the corona discharge electrode 7 is used at the top of the electric field with a high voltage The insulator 11 is electrically insulated from the shell 10, the corona discharge electrode 7 is vibrated by the middle or top cathode 9, the dust collection anode plate is vibrated by the bottom anode 3, the ash falls into the ash hopper 14 for collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com