Coulomb electric precipitator

An electrostatic precipitator and electric field technology, applied in electrode structure, electrostatic separation, electrode cleaning, etc., can solve problems such as high cost and inability to maintain high dust removal efficiency, and achieve the effect of saving energy, saving overall cost and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

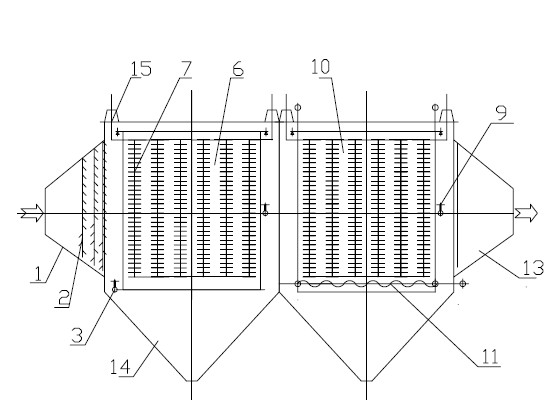

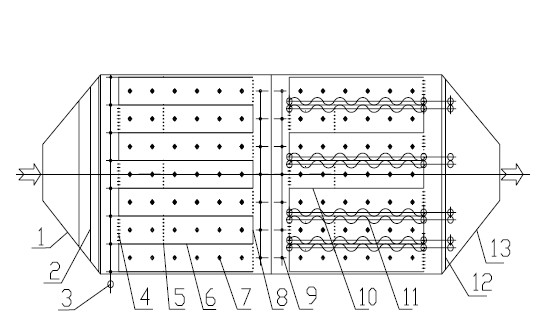

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

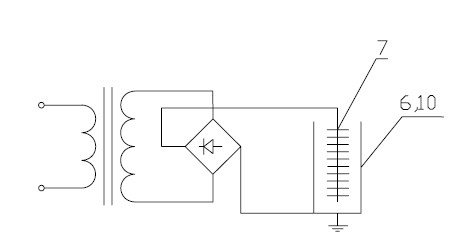

[0033] refer to Figure 1 to Figure 14 , a Coulomb electrostatic precipitator, including a dust removal box, the two ends of the dust removal box are installed with an air inlet box 1 and an exhaust box 13, and the dust removal box is provided with a front electric field near the side of the air inlet box. The front electric field includes fixed pole plates 6 and corona discharge electrodes 7 arranged alternately, the bottom of the fixed pole plates 6 is provided with anode rapping 3, and the corona discharge electrode 7 is provided with cathode rapping 9, and the fixed pole plates 6 are provided with cathode rapping 9. There are fixed plate ventilation holes on the plate 6 for flue gas to pass through, and electric field channels are formed between adjacent fixed plates. Among them, the inlet ends of the odd-numbered electric field channels are open and the outlet end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com