Differential movable type transverse electrode electrostatic precipitator

A transverse electrode and electrostatic precipitator technology, applied in the field of electrostatic precipitators, can solve the problems of unsatisfactory discharge, shrinking dust collection area, and inability to use products to meet standards, etc. The effect of secondary flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

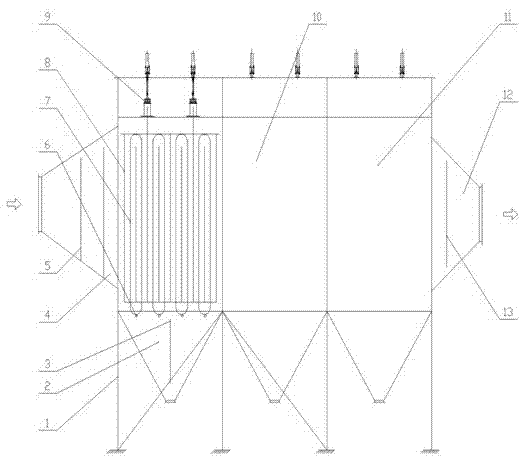

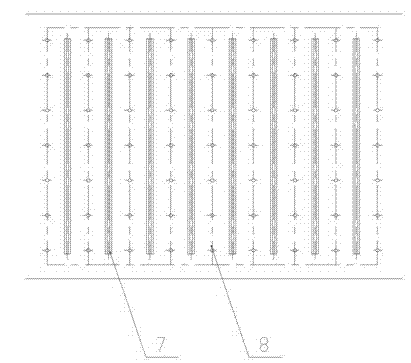

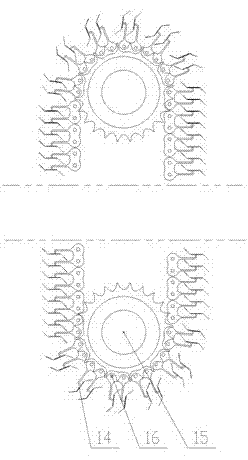

[0027] like figure 1 As shown, the differential mobile horizontal electrode electrostatic precipitator according to the present invention mainly includes a bottom steel frame 1, an ash bucket 2, an ash bucket baffle plate 3, an inlet head 4, an inlet airflow uniform distribution 5, and an anode plate toggle Device 6, anode system 7, cathode system 8, cathode top rapping system 9, casing 10, top cover 11, outlet head 12 and outlet groove plate 13, wherein:

[0028] The bottom steel frame 1 supports the upper shell 10, the two ends of the shell 10 are provided with an inlet head 4 and an outlet head 12, and the lower part is provided with an ash bucket 2, and the ash bucket 2 is equipped with an ash bucket baffle 3, and the inlet head 4 is equipped with an inlet airflow uniform distribution device 5, which can make the flue gas evenly distributed in the box, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com